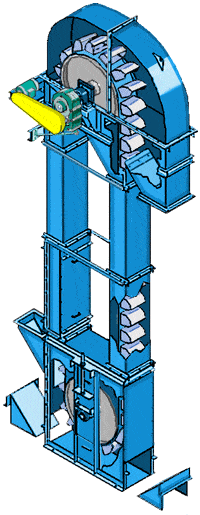

Bucket elevator is suitable for conveying powdery,granular and small lump materials with low or no abrasiveness,such as cement,coal,limestone,dry clay,clinker and the materials temperature can not exceed 250℃.The materials directly enter into bucket elevator and can be guided to discharge.Materials is raised to the top by the chain and bucket and discharged under its own gravity.Bucket elevator has obvious advantages of simple structure,low consumption,small size,saving floor space,operating in a fully enclosed environment,good seal,no dust,avoiding pollution of the environment,big capacity,high lifting height,and

Bucket elevator Main technical parameters:

| 规格 Model | 处理量(m³/h) Capacity | 链速(m/min) Chain speed | 物料粒度(mm) Material size | 料斗Hopper | 斗距(mm) Distance of bucket | |

| 斗容(L) Bucket capacity |

斗宽(mm) Bucket width | |||||

| TH160 | 16 | 69.7 | <20 | 1.9 | 160 | 500 |

| TH210 | 18 | 63.2 | <30 | 2.4 | 210 | 500 |

| TH315 | 35 | 42.5 | <30 | 6 | 315 | 512 |

| TH350 | 42 | 40.1 | <30 | 7.2 | 350 | 512 |

| TH400 | 58 | 37.6 | <30 | 9.5 | 400 | 512 |

| TH500 | 73 | 35.8 | <40 | 15 | 500 | 688 |

| TH630 | 114 | 31.8 | <40 | 23.6 | 630 | 688 |

the traction member surrounds the driving wheel and the follower wheel to form a closed circuit, the hopper is uniformly fixed on the traction member according to the preset spacing, and the shell seals the dustpan and the traction belt. The material enters the running hopper through the inlet, and is vertically transported along the elevator cylinder with the traction member to the top driving wheel, where the material is thrown off under the effect of centrifugal force, and finally discharged out of the equipment through the discharge port.

Product Structure:The bucket elevator is mainly composed of shell, driving wheel (head wheel), driven wheel (bottom wheel), traction components (belt or chain) and hopper and other core components.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

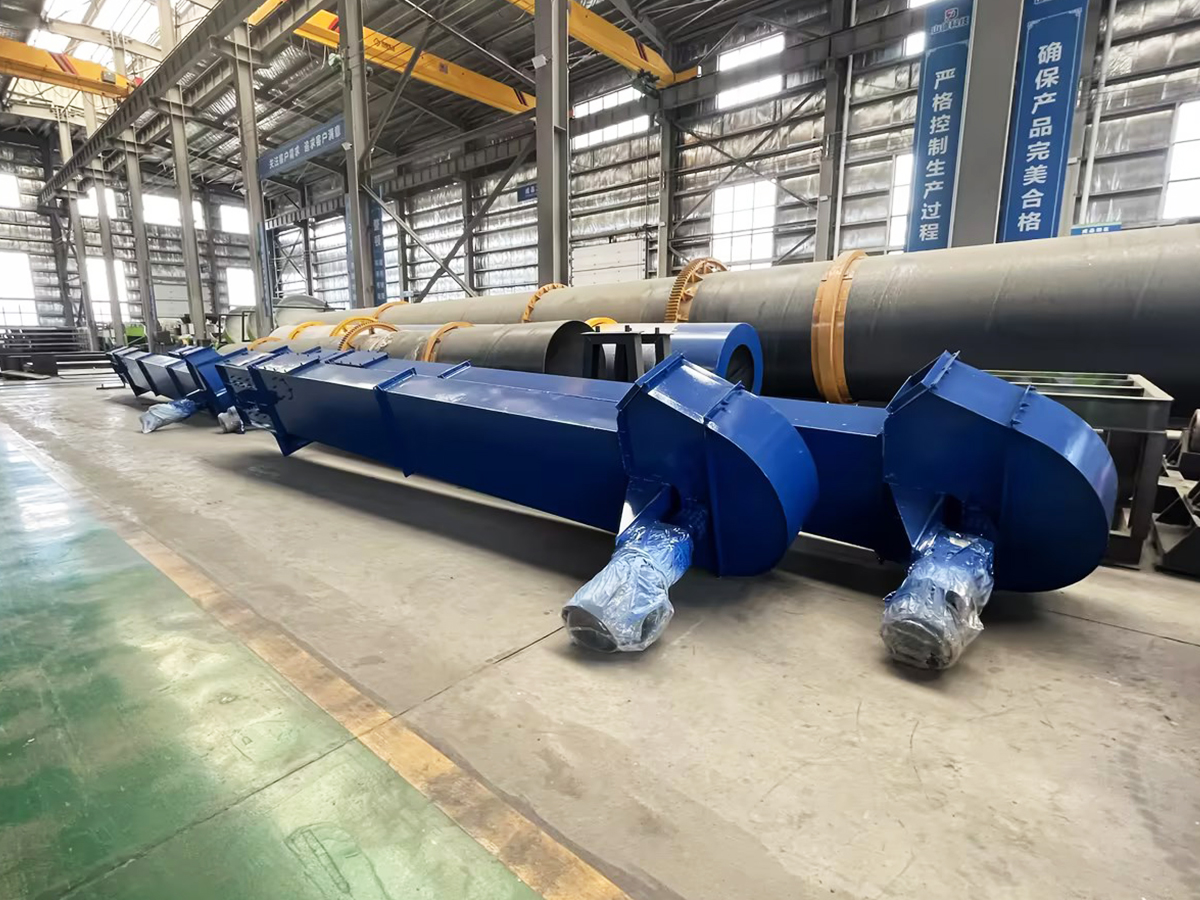

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine