What are the respective roles of cone crushers and jaw crushers in the gold ore beneficiation proces

Time:2026-01-15

Author:

In gold ore beneficiation, cone crushers and jaw crushers play pivotal roles in multi-stage crushing, progressively reducing ore particle sizes to meet the feed requirements of subsequent grinding and separation processes. Below is an analysis of their functions, equipment characteristics, and application scenarios:

I. Functional Stages: Sequential Cooperation in Multi-Stage Crushing

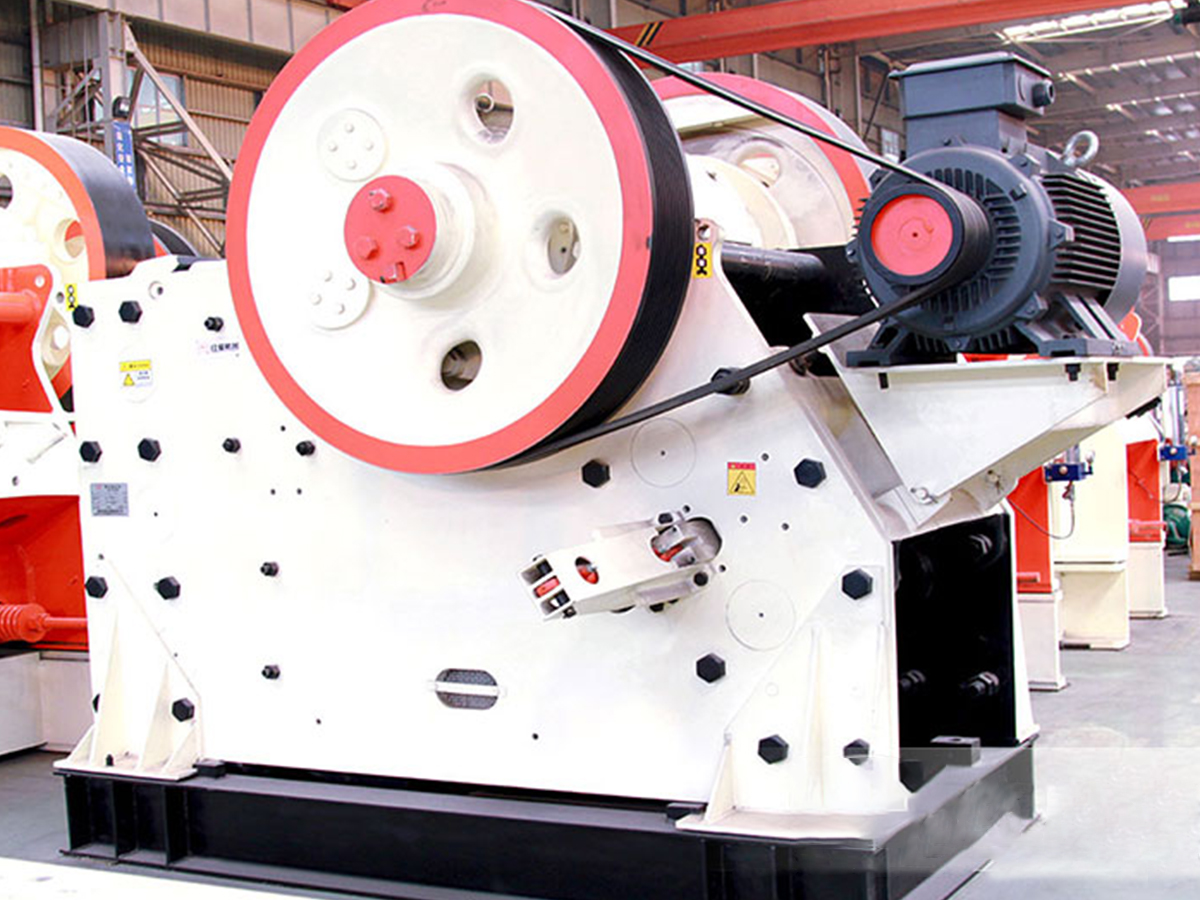

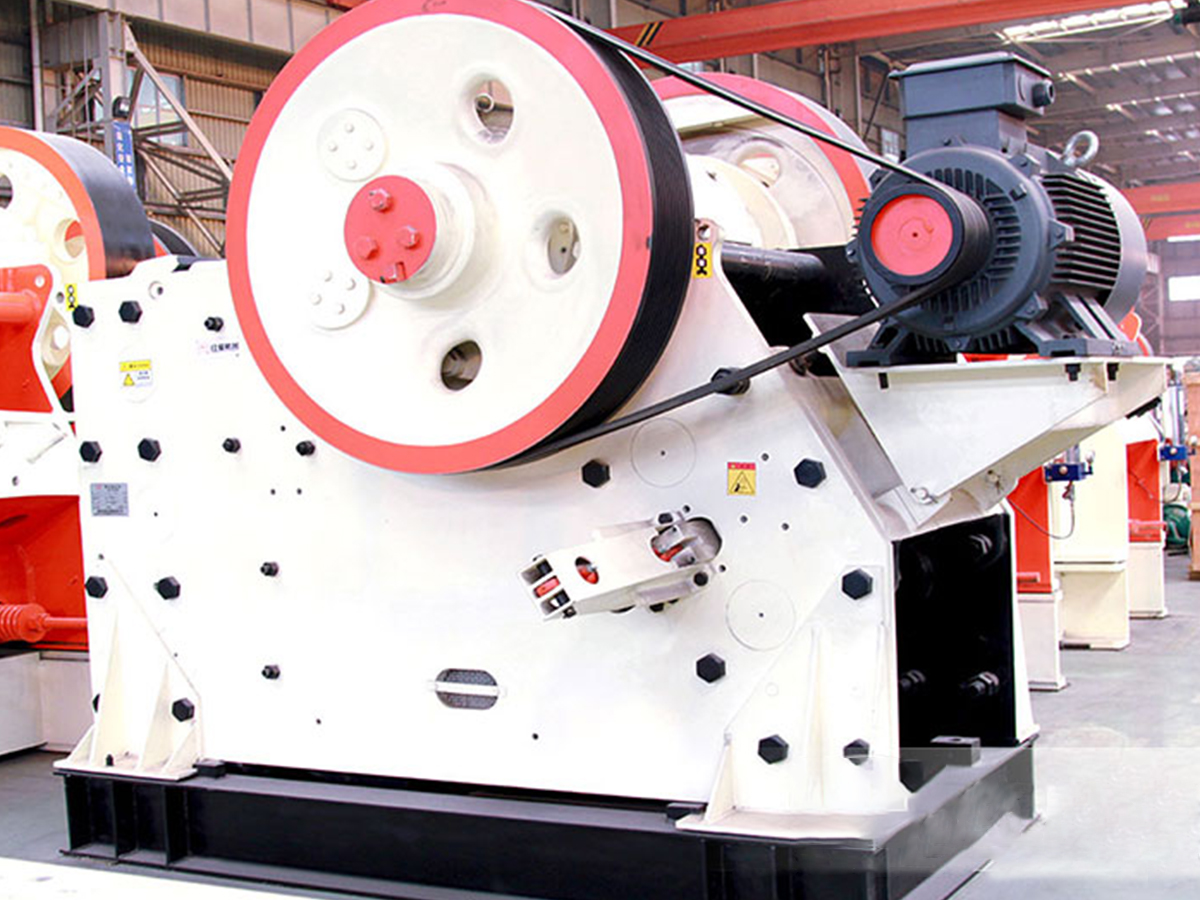

- Jaw Crushers: Core Equipment for Primary Crushing

- Functional Positioning: As the "first line of defense" in beneficiation, jaw crushers break large raw ores (typically 500–1,500 mm in diameter) into medium-sized particles (100–300 mm), providing suitable feed for secondary and tertiary crushing.

- Typical Application: In open-pit gold mining, jaw crushers reduce ore with a maximum particle size of 1,200 mm to 150–250 mm, preventing blockages in downstream equipment (e.g., cone crushers) and ensuring process continuity.

- Data Support: A quartz vein-type gold beneficiation plant achieved a 95%+合格率 (pass rate) for primary crushed products (particle size ≤250 mm) using jaw crushers, stabilizing operations for secondary crushing.

- Cone Crushers: Dominant Equipment for Secondary and Tertiary Crushing

- Functional Positioning: Cone crushers are divided into standard types (for secondary crushing) and short-head types (for tertiary crushing), further reducing ore particle sizes to 30–40 mm and 5–15 mm, respectively, to meet grinding mill feed requirements.

- Typical Application: A copper mine adopted a "jaw crusher (primary) + standard cone crusher (secondary) + short-head cone crusher (tertiary)" flowsheet, achieving a final particle size of <10 mm. This reduced ball mill grinding time by 30% and energy consumption by 25%.

- Data Support: A gold mine in Luanchuan, Henan, used a GYP-900 cone crusher to produce 80% of its output in the -10 mm fraction with a weighted average particle size of 6.4 mm, significantly improving grinding efficiency.

II. Equipment Characteristics: Structural Advantages and Performance Differences

- Jaw Crushers: High Adaptability and Low Maintenance Costs

- Structural Features: Crushing is achieved through the periodic squeezing and releasing motion of movable jaws, with key components including fixed jaw plates, movable jaw plates, and eccentric shafts. The design ensures simplicity and durability of wear parts (e.g., jaw plates).

- Performance Advantages:

- Strong Adaptability: Handles hard rock gold ores (e.g., granite-type) with compressive strengths ≤320 MPa. Wear part lifespan exceeds that of impact crushers by 30%+.

- Easy Maintenance: Supports standalone or multi-machine串联 (tandem) operations. The discharge port gap is adjustable (via shim plates) to meet varying particle size requirements for coarse ores.

- Case Study: A hard-rock gold mine reduced over-crushing (excessively fine particles) to <5% and improved particle size uniformity by 20% using jaw crushers.

- Cone Crushers: Energy Efficiency and Precise Particle Size Control

- Structural Features: Continuous crushing is achieved through the periodic squeezing motion between the crushing cone and concave, with key components including wear-resistant crushing walls, concaves, and eccentric sleeves. The design emphasizes "inter-particle crushing" mechanisms.

- Performance Advantages:

- Energy Savings: Reduces grinding energy consumption via "more crushing, less grinding." A tungsten-molybdenum ore plant shortened grinding time to 25 minutes and cut unit energy consumption by 30% using short-head cone crushers.

- Precise Particle Control: Adjustable parameters (e.g., eccentric static moment, discharge gap) enable precise control over product size. A graphite mine achieved 98% of its output in the -2 mm fraction (with optional control to <1 mm) using a GYP-300 cone crusher while preserving flake structures.

- Case Study: A graphite beneficiation plant used short-head cone crushers for fine crushing, achieving 98% particle size compliance and intact flake morphology.

III. Application Scenarios: Selection Based on Ore Properties and Process Needs

- Jaw Crusher Applications

- High-Hardness Ores: Effective for granite- or amphibolite-type gold ores due to their "squeezing crushing" mechanism, which minimizes equipment wear.

- Large-Scale Production: Suitable for plants processing 500–10,000 t/d of ore, supporting multi-machine tandem operations for high throughput.

- Primary Crushing Pre-Treatment: Provides stable feed for secondary/tertiary crushers (e.g., cone crushers) by preventing large ore blockages.

- Cone Crusher Applications

- Secondary/Tertiary Crushing Needs: Standard types are used for secondary crushing (e.g., reducing primary crushed ore to 30–40 mm), while short-head types handle tertiary crushing (e.g., reducing secondary crushed ore to 5–15 mm).

- Energy-Saving Goals: Reduces grinding energy costs via "more crushing, less grinding," ideal for cost-sensitive beneficiation plants.

- High-Precision Particle Control: Essential for scenarios requiring uniform particle sizes, such as metal concentrate crushing or non-metallic mineral deep processing.

Summary: Synergistic Effects Enhancing Beneficiation Efficiency

Jaw crushers and cone crushers form a "primary-secondary-tertiary" crushing relay in gold ore beneficiation:

- Jaw crushers excel in primary crushing with high adaptability and low maintenance, providing stable feed for downstream processes.

- Cone crushers enhance secondary/tertiary crushing efficiency through energy savings and precise particle control, significantly reducing grinding energy consumption and improving separation accuracy.

Their synergistic operation optimizes particle size distribution, energy efficiency, and cost control, making them indispensable for modern beneficiation plants aiming for high-efficiency, eco-friendly production.