The ball mill is an important fine grinding equipment, widely used in the cement industry.

Due to its relatively long cylinder, this type of mill allows materials to be ground for an extended period inside, resulting in a higher fineness of the finished product.

The specifications of a ball mill are expressed as the product of the inner diameter (D) of the cylinder and its length (L), such as a Φ3.2x4.5 ball mill.

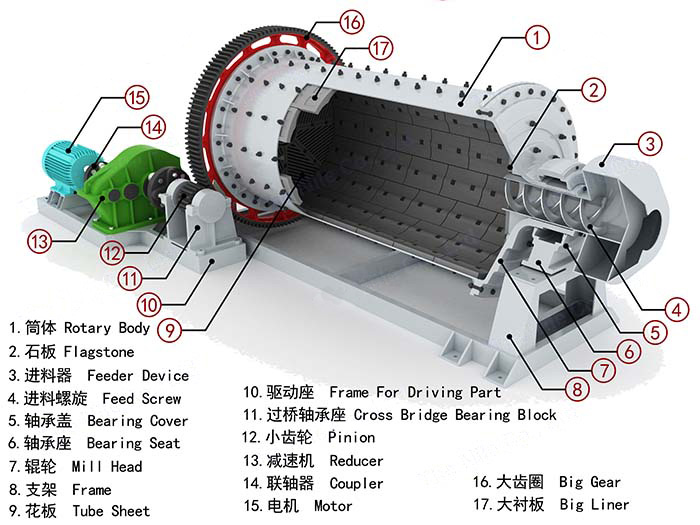

Although ball mills are classified into various types based on differences in production methods, specifications, discharge mechanisms, support structures, and drive systems, they generally share a similar structure, primarily consisting of the following basic components:

-

Feed Device: This includes a feed hopper, a screw feed cylinder, or a feed conical cylinder.

-

Support Device: Support can be provided by main bearings at both ends, a hybrid support system (combining main bearings and slide shoes), or slide shoe supports at both ends.

-

Rotating Section: This comprises the hollow shaft, the mill cylinder, and internal components such as diaphragm plates, liners, and retaining rings.

-

Discharge Device: Discharge can occur at the periphery, center, or intermediate points.

-

Drive System: This includes two forms: peripheral drive and central drive, encompassing the main motor, auxiliary motor, reducer, drive shaft, and the large and small gears for peripheral drive systems.