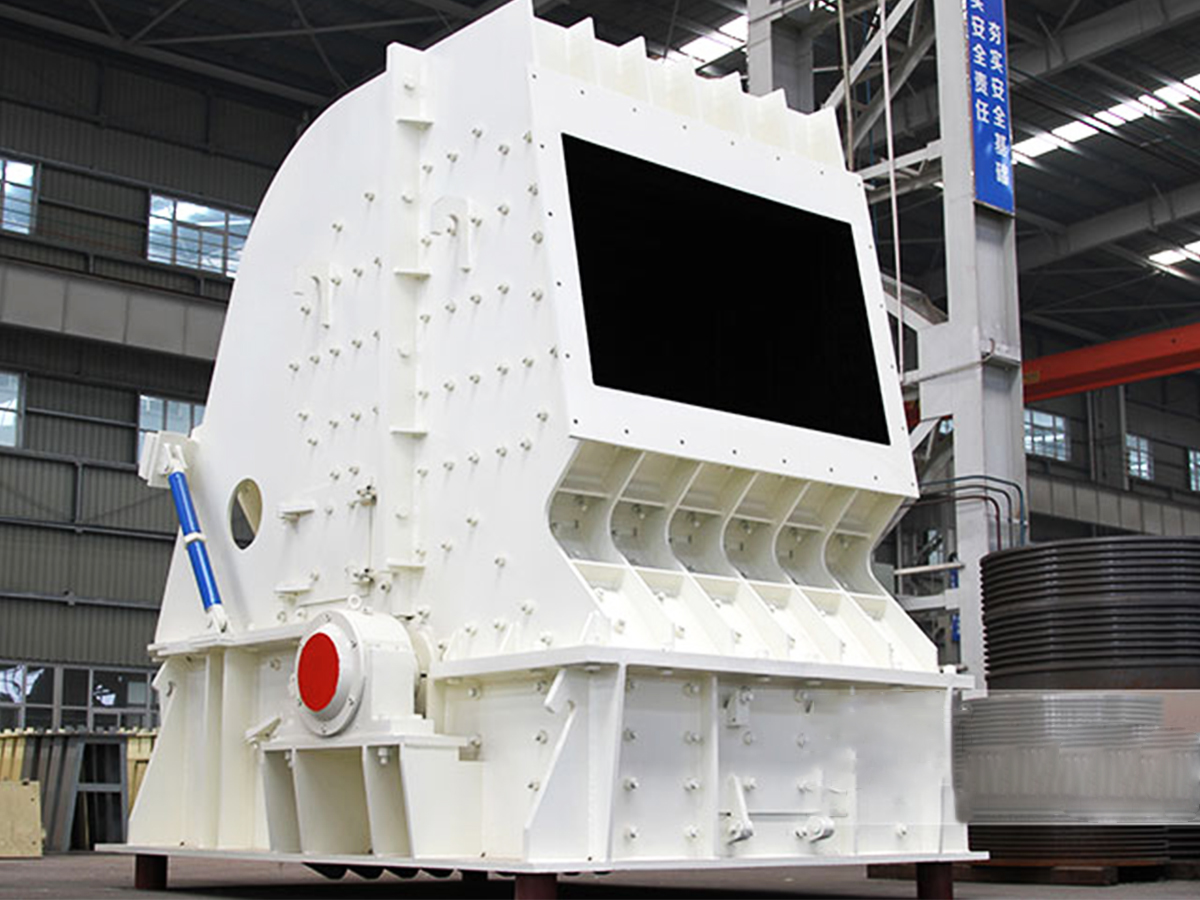

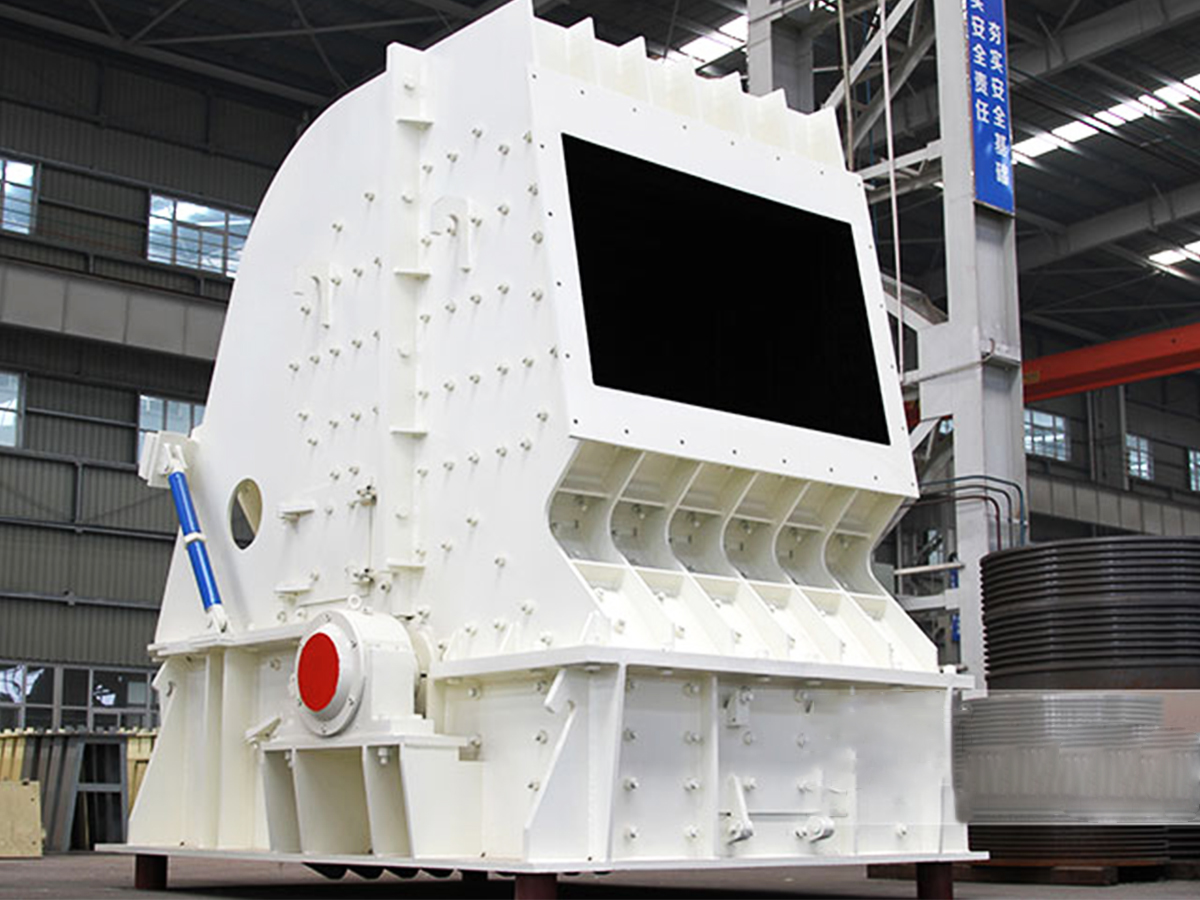

The application of crushing equipment in mineral processing

Time:2026-01-14

Author:

Crushing equipment plays a pivotal role in the mineral processing technology, serving as the initial step in the entire mineral processing flow and exerting a profound impact on the efficiency, costs, and final product quality of subsequent operations. The following provides a detailed explanation of the functions of crushing equipment in mineral processing from multiple aspects:

I. Reducing Particle Size to Meet Requirements for Subsequent Operations

- Creating Conditions for Grinding Operations:

- Crushing equipment uses mechanical force to break raw ore into an appropriate particle size, providing suitable feed for grinding operations. Grinding operations require further refinement of ores to enhance mineral liberation and facilitate subsequent separation operations. If the particle size of the raw ore is too large, grinding equipment will struggle to process it effectively, resulting in low grinding efficiency and increased energy consumption.

- Through multi-stage crushing (such as coarse, medium, and fine crushing), crushing equipment gradually breaks raw ore into the particle size range required by grinding equipment, ensuring the smooth progress of grinding operations.

- Adapting to Requirements of Different Separation Equipment:

- Different separation equipment has varying requirements for particle size. For example, flotation equipment typically requires finer particle sizes to enable sufficient contact and attachment of mineral particles to bubbles, while gravity separation equipment may have specific particle size range requirements to ensure effective separation.

- By adjusting the reduction ratio and discharge particle size, crushing equipment can meet the needs of different separation equipment, providing suitable material conditions for subsequent operations.

II. Improving Mineral Processing Efficiency and Reducing Production Costs

- Increasing Mineral Liberation:

- Through crushing operations, the connections between valuable minerals and gangue minerals in ores are broken, increasing mineral liberation. This facilitates the recovery of valuable minerals and the separation of gangue minerals in subsequent separation operations, improving mineral processing recovery rates.

- The efficient crushing capability of crushing equipment ensures thorough liberation of ores, providing high-quality materials for subsequent operations.

- Reducing Energy Consumption and Wear:

- By optimizing the crushing chamber shape and crushing method, crushing equipment can improve crushing efficiency and reduce energy consumption. For example, crushing equipment utilizing the lamination crushing principle can reduce energy consumption while ensuring effective crushing results.

- Wear-resistant components of crushing equipment (such as crushing walls and bowl liners) are made of high-wear-resistant materials, extending equipment lifespan and reducing replacement frequency and maintenance costs.

III. Adapting to Different Ore Properties and Achieving Flexible Production

- Handling Various Ore Types:

- Crushing equipment can process ores of various hardness levels, including high-hardness ores (such as iron ore and copper ore) and soft ores (such as coal and limestone). By selecting appropriate crushing equipment and processes, efficient crushing of different ore types can be achieved.

- Crushing equipment can also handle raw ores of different particle sizes, including large ore blocks and fine-grained ores. By adjusting the feed and discharge port sizes of crushing equipment, it can adapt to the processing needs of raw ores with different particle sizes.

- Implementing Multi-stage Crushing and Flexible Adjustment:

- Crushing equipment typically employs a multi-stage crushing process, including stages such as coarse, medium, and fine crushing. This multi-stage crushing process can be flexibly adjusted based on ore properties and subsequent operational requirements to achieve optimal crushing results.

- During production, parameters of crushing equipment (such as rotational speed and discharge port size) can be adjusted according to actual conditions to adapt to changes in ore properties and production volume requirements.

IV. Ensuring Production Safety and Reducing Environmental Pollution

- Ensuring Production Safety:

- Crushing equipment is designed and manufactured with production safety factors in mind. For example, the use of protective devices and safety interlock systems can prevent accidental incidents during equipment operation, ensuring the safety of operators.

- Crushing equipment is also equipped with dust removal systems to reduce dust pollution generated during the crushing process and improve the working environment.

- Reducing Environmental Pollution:

- Noise and vibration generated during the crushing process can be reduced through the adoption of noise reduction and vibration mitigation measures, minimizing the impact on the surrounding environment.

- Crushing equipment can also be used in conjunction with environmental protection equipment such as dust removal equipment and wastewater treatment equipment to achieve green and sustainable mineral processing production.