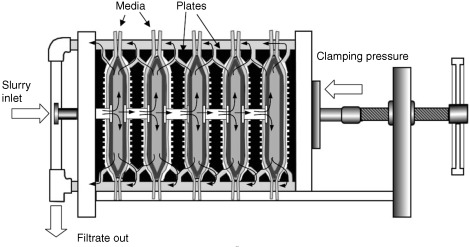

Plate frame pressure filter is a kind of intermittent solid-liquid separation equipment,use electromechanical integration design,reasonable structure,simple and convenient operation;can achieve filter platecompaction,keeping pressure,fiter plate release and other processes.The filter chamber is made of box plate and the filter frame,the effect of the pressure feed pump will be expected to be sent into the filter chamber,solid and liquid separation by filtration matter.Widely used in mining,chemical metallurgy and.

Plate frame pressure filter Main technical parameters:

| Model | Filtering area(m²) | Filter chamber quantty (pcs) | Filter plate model (mm) | Filter cake thickness (mm) | Filter chamber volume (m³) | Filtration pressure (Mpa) | Dimensions(mm) | Power(kw) | Weight(kg ) |

| XMZ100-1000-30U | 100 | 58 | 1000×1000 | 30 | 1.635 | 0.5-1.6 | 5890×1500×1350 | 2.2 | 4360 |

| XMZ110-1090-30U | 110 | 54 | 1090×1090 | 30 | 1.65 | 0.5-1.6 | 5760×1590×1450 | 5060 | |

| XMZ120-1090-30U | 120 | 59 | 1090×1090 | 30 | 1.8 | 0.5-1.6 | 6065×1590×1450 | 5360 | |

| XMZ150-1250-30U | 150 | 56 | 1250×1250 | 30 | 2.28 | 0.5-1.6 | 6200×1750×1600 | 4 | 7500 |

| XMZ180-1250-30U | 180 | 67 | 1250×1250 | 30 | 2.72 | 0.5-1.6 | 7230×1750×1600 | 8500 | |

| XMZ200-1250-30U | 200 | 74 | 1250×1250 | 30 | 3 | 0.5-1.6 | 7690×1750×1600 | 9000 | |

| XMZ250-1250-30U | 250 | 93 | 1250×1250 | 30 | 3.8 | 0.5-1.6 | 9015×1750×1600 | 10500 | |

| XMZ300-1500-30U | 300 | 74 | 1500×1500 | 30 | 4.48 | 0.5-1.6 | 9120×2330×1800 | 5.5 | 19200 |

| XMZ350-1500-30U | 350 | 87 | 1500×1500 | 30 | 5.25 | 0.5-1.6 | 10040×2330×1800 | 21300 | |

| XMZ400-1500-30U | 400 | 99 | 1500×1500 | 30 | 5.96 | 0.5-1.6 | 10890×2330×1800 | 23300 | |

| XMZ450-1500-30U | 450 | 112 | 1500×1500 | 30 | 6.74 | 0.5-1.6 | 11815×2330×1800 | 25400 | |

| XMZ500-1500-30U | 500 | 125 | 1500×1500 | 30 | 7.51 | 0.5-1.6 | 12740×2330×1800 | 27500 | |

| XMZ600-2000-40U | 600 | 113 | 2000×1500 | 40 | 11.98 | 0.5-1.2 | 13010×2620×2650 | 11 | 37855 |

| XMZ700-2000-40U | 700 | 133 | 2000×1500 | 40 | 14.08 | 0.5-1.2 | 14610×2620×2650 | 41074 | |

| XMZ800-2000-40U | 800 | 110 | 2000×2000 | 40 | 11.99 | 0.5-1.2 | 13540×3030×2400 | 11 | 43972 |

| XMZ1000-2000-40U | 900 | 127 | 2000×2000 | 40 | 14.9 | 0.5-1.2 | 14920×3030×2400 | 56000 |

The filter cloth acts as a medium that allows the liquid to pass through while retaining the solids. The result is the formation of filter cakes within the chambers and the collection of filtrate, enabling effective solid-liquid separation.

Filtration: The chamber filter press applies pressure to the slurry by either hydraulic or mechanical means. This pressure forces the liquid portion of the slurry to pass through the filter cloth while retaining the solid particles within the chambers.

Cake Formation: As the liquid passes through the filter cloth, a layer of solid particles, known as the filter cake, forms on the surface of the cloth within each chamber.

Filtrate Collection: The liquid portion of the slurry, called the filtrate, passes through the filter cloth and collects in a drainage system or collection channel.

Cloth Cleaning: Over time, the filter cloths may become clogged with accumulated solids, reducing filtration efficiency. Periodic cleaning or replacement of the filter cloths is necessary to maintain the performance of the chamber filter press.

Plate and frame filter presses have several advantages over other types of filter presses, including:

1. High filtration efficiency: Plate and frame filter presses can achieve high filtration efficiency due to the large surface area of the plates and the ability to adjust the pressure and flow rate of the liquid being filtered.

2. Low maintenance: Plate and frame filter presses are relatively simple in design and have few moving parts. Which makes them easy to maintain and repair.

3. Flexibility: Plate and frame filter presses can suit various applications. They can filter a wide range of liquids and solids.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine