The Working Principle of Jaw Crusher: Mechanical Force Reshaping Material Morphology

Jaw crushers, as the cornerstone of primary crushing in mining, construction, and metallurgical industries, utilize mechanical force to reduce large rocks into manageable sizes. Their working principle combines kinematic design with material physics, enabling efficient processing of materials with compressive strengths up to 200 MPa.

Core Structural Components and Motion Mechanism

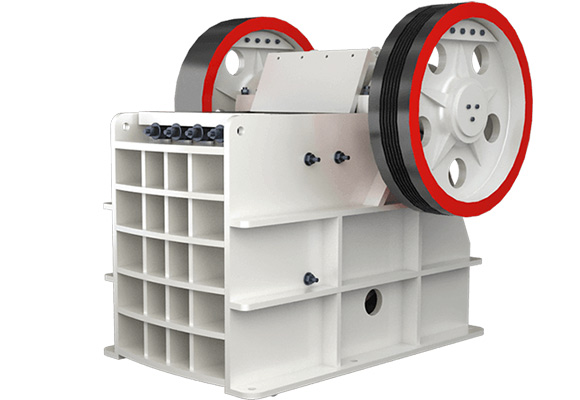

The fundamental structure consists of a fixed jaw plate (stationary jaw) and a movable jaw plate (swing jaw), forming a V-shaped crushing chamber. The movable jaw is suspended from an eccentric shaft driven by a motor via V-belts and pulleys. During operation, the eccentric shaft generates a reciprocating motion, causing the movable jaw to swing in an elliptical trajectory. This motion creates two critical phases:

- Compression Phase: As the movable jaw moves toward the fixed jaw, the crushing chamber narrows, exerting compressive forces on the material. This phase involves simultaneous actions of squeezing, splitting, and abrasion, breaking the material into smaller fragments.

- Discharge Phase: When the movable jaw retracts, the chamber expands, allowing crushed material to fall through the bottom outlet under gravity. The cycle repeats continuously, achieving mass production.

Modern jaw crushers like the European-type models incorporate optimized kinematics. For instance, the movable jaw's upper section follows a circular motion while the lower section moves elliptically, enhancing crushing efficiency by 20-30% compared to traditional simple-swing designs. This reduces energy consumption by 15-30% while maintaining a crushing ratio of 4:1 to 6:1.

Material Processing Dynamics

The crushing process involves three stages:

- Initial Loading: Material enters the chamber through the top inlet, accumulating between the jaws. The chamber's deep design minimizes dead zones, ensuring uniform material distribution.

- Multistage Crushing: During compression, materials undergo primary fracture from direct pressure, secondary fracture from interparticle collision, and tertiary fracture from abrasion against jaw plates. This multistage mechanism produces cubical end products with uniform particle size distribution.

- Controlled Discharge: Adjustable wedge or shim systems regulate the outlet gap (40-300 mm in European models), enabling precise control over final product size. Hydraulic overload protection systems automatically widen the discharge gap when uncrushable materials enter, preventing equipment damage.

Technological Evolution and Applications

From the early 19th-century Blake-type crushers to modern high-performance models, jaw crushers have evolved through innovations like:

- Compound Pendulum Motion: Reducing weight by 20-30% while improving stroke characteristics

- Modular Design: Enabling quick replacement of wear parts like manganese steel jaw plates

- Mobile Integration: Combining with vibrating feeders and conveyors in tracked or wheeled platforms for onsite crushing

These advancements make jaw crushers indispensable for processing basalt, river pebbles, construction waste, and other hard materials. Their applications span mining (primary crushing), recycling (building debris processing), and chemical industries (raw material preparation), with capacities ranging from 1 to 675 tons per hour.

Conclusion

The jaw crusher's working principle exemplifies mechanical engineering ingenuity, transforming brute force into controlled material deformation. Through continuous optimization of jaw motion trajectories, chamber geometries, and power transmission systems, these machines achieve the dual goals of high productivity and operational reliability, cementing their status as essential equipment in heavy industries worldwide.