- output:40-200 T/H

- Feed size:≤270

- Motor power:0.55*2-2.22*2 KW

Motor vibrating feeder is widely used in mining,metallurgy,coal,building materials,light industry,chemical industry,electric power,food and other industries,for transfering the massive,granular and powdery materials from the storage silo or hopper to the receiving device uniformly,continuously or quantitatively.For example,it can send materials during the process of crushing,coal separation,screening,transportation, packaging,etc.As an ordinary groove feeder,GZG series feeder is suitable for feeding materials without.

| 型号 Model | 最大给料粒度 Max.input size (mm) | 给料能力 Capacity(t/h) | 功率 Power(kw) | 振幅(mm) Amplitude | 外形尺寸(mm) Overall dimension | 备注 Note |

| GZG50-4 | 70 | 40 | 0.55×2 | 2-3 | 1598×810×675 | 轻型 Light type |

| GZG60-4 | 90 | 50 | 0.55×2 | 2-3 | 1865×910×675 | |

| GZG70-4 | 110 | 60 | 0.75×2 | 2-4 | 1930×1030×764 | |

| GZG80-4 | 140 | 80 | 0.75×2 | 2-4 | 1930×1126×764 | |

| GZG90-4 | 170 | 95 | 1.1×2 | 2-4 | 1930×1226×815 | |

| GZG100-4 | 200 | 110 | 1.1×2 | 2-5 | 1930×1326×915 | |

| GZG110-4 | 220 | 130 | 1.5×2 | 2-5 | 1930×1426×983 | |

| GZG80-4 | 140 | 80 | 1.1×2 | 2-5 | 1945×990×826 | 重型 Heavy type |

| GZG100-4 | 200 | 110 | 1.5×2 | 2-5 | 2130×1198×908 | |

| GZG110-4 | 220 | 130 | 1.5×2 | 2-5 | 2145×1298×920 | |

| GZG125-4 | 240 | 160 | 1.5×2 | 2-5 | 2345×1448×920 | |

| GZG200-4 | 270 | 200 | 2.2×2 | 3-5 | 2645×1690×995 |

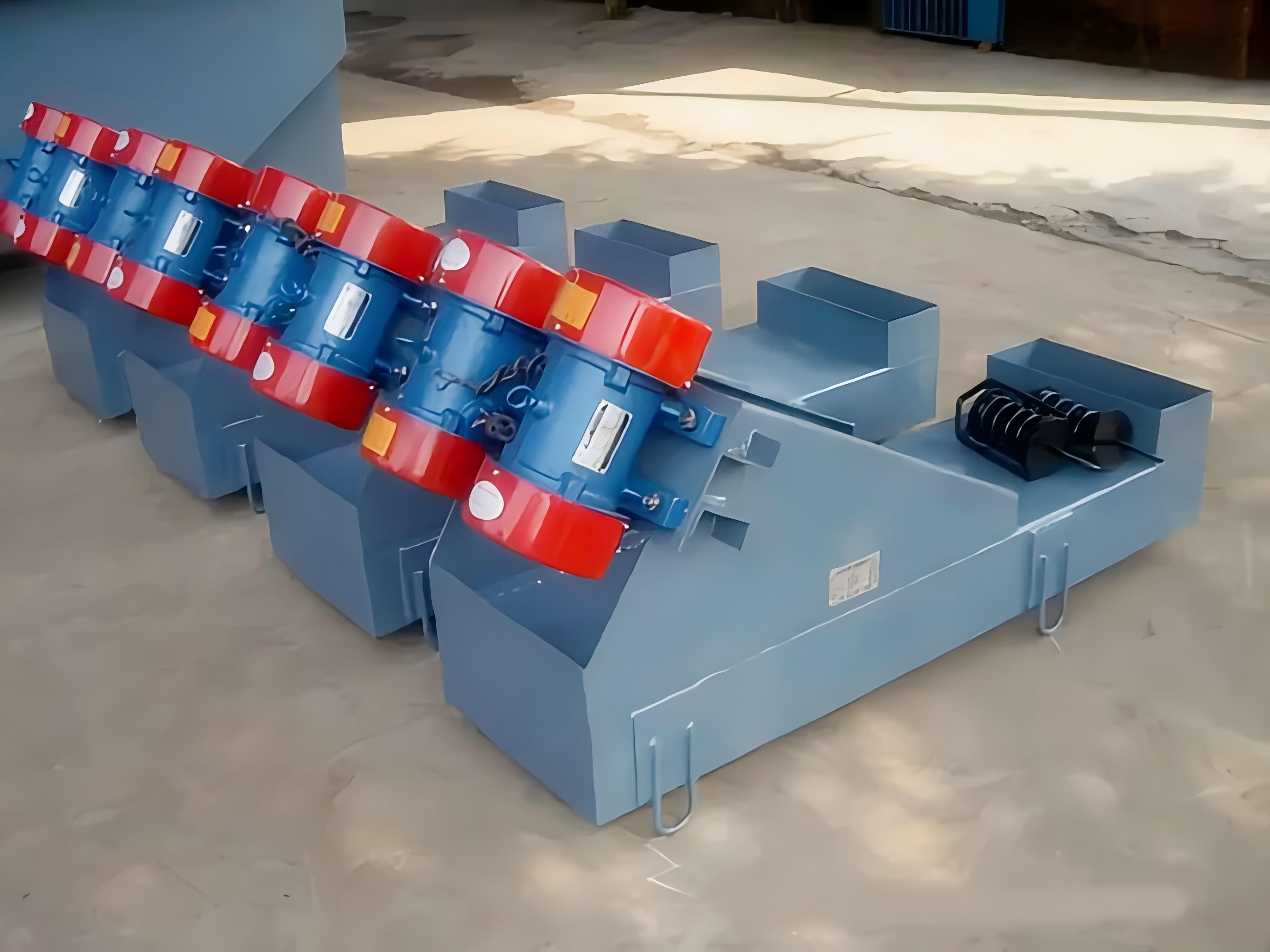

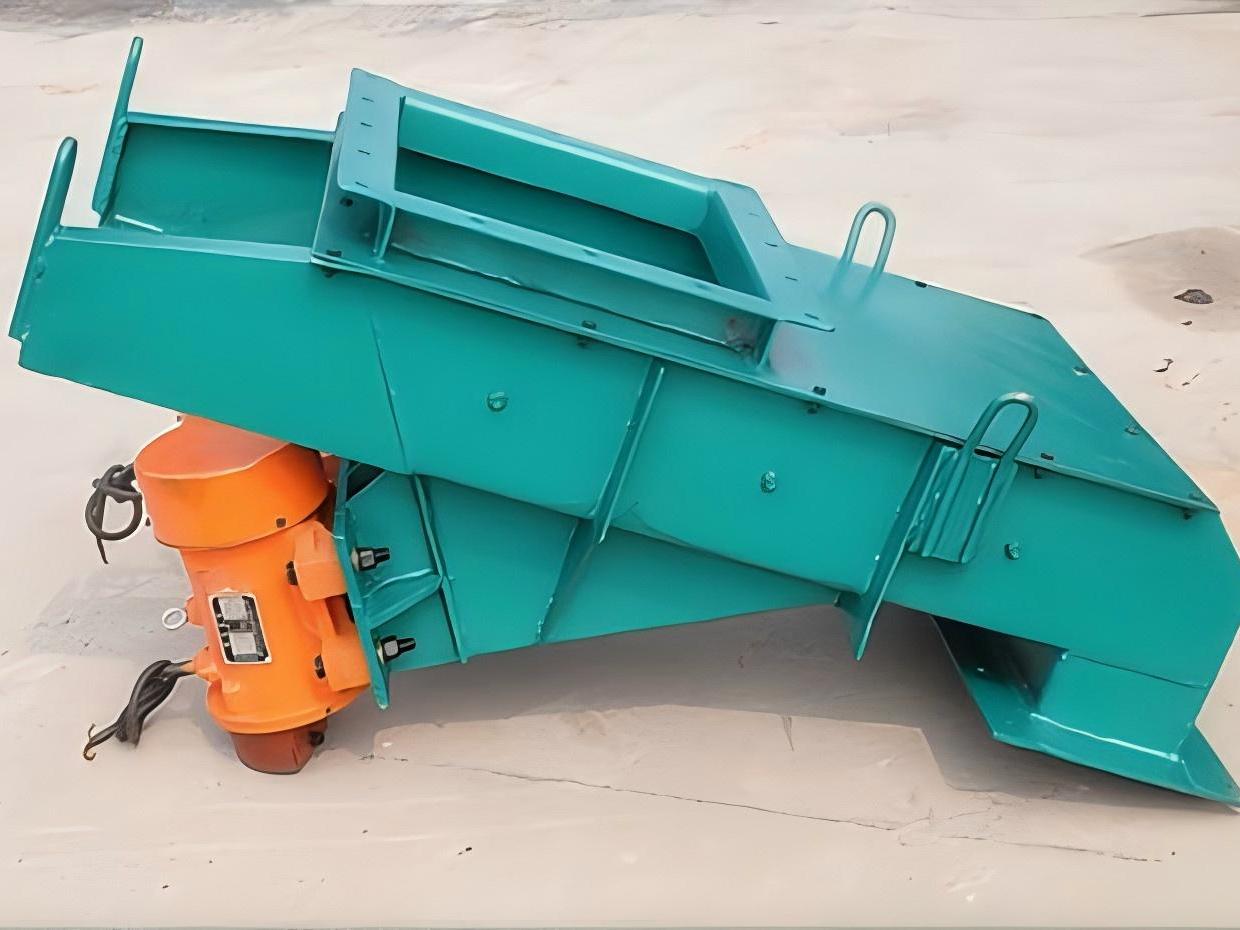

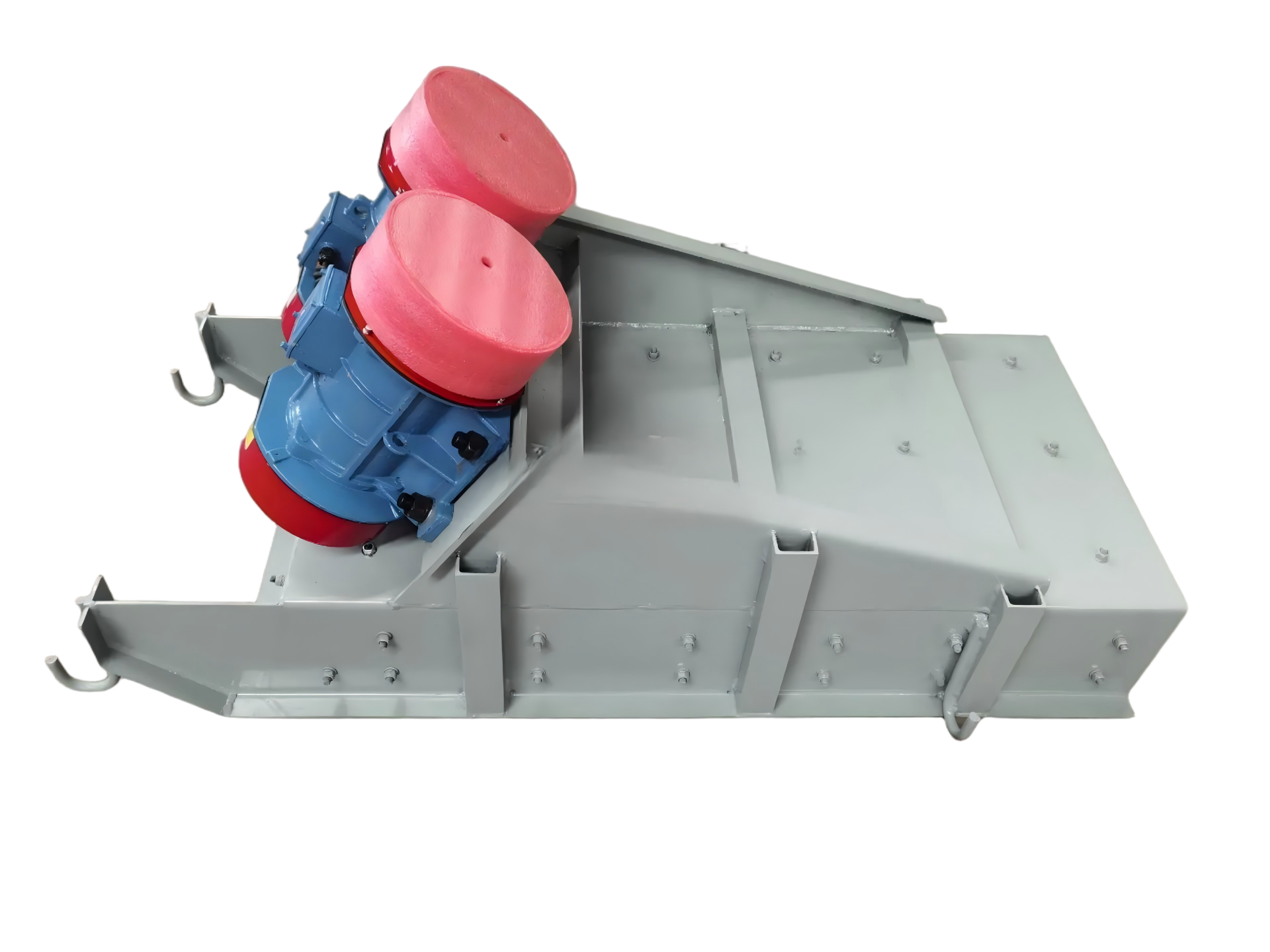

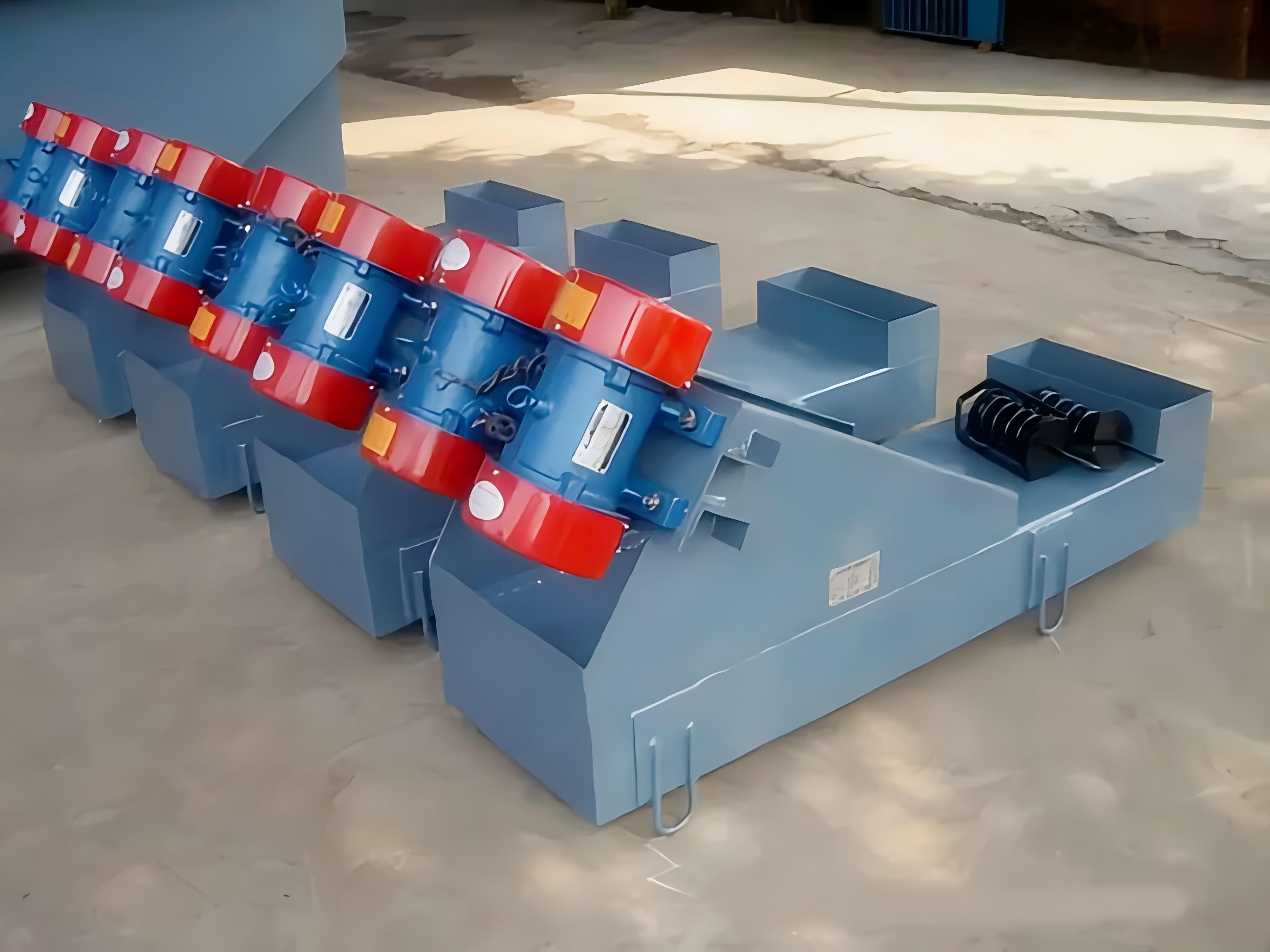

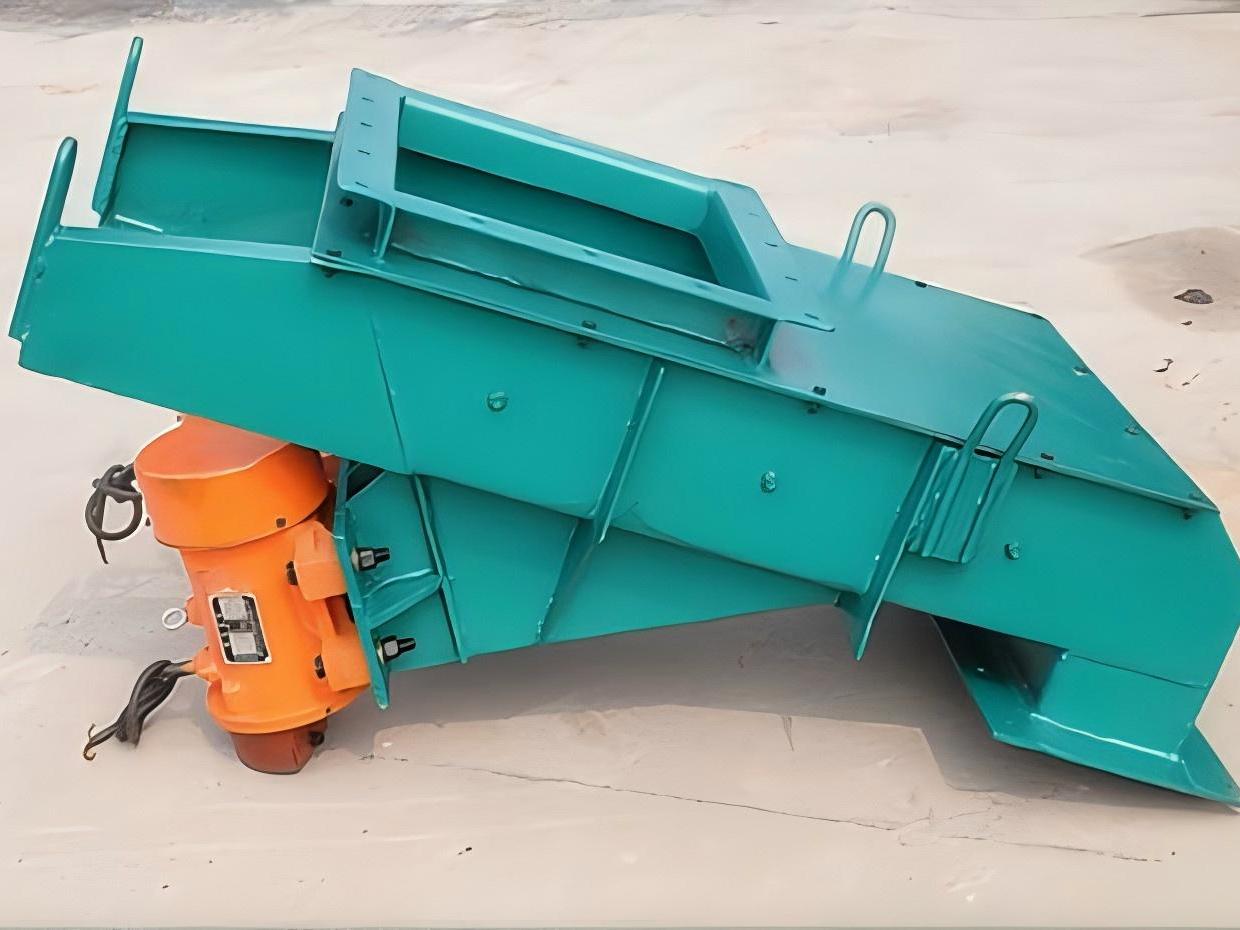

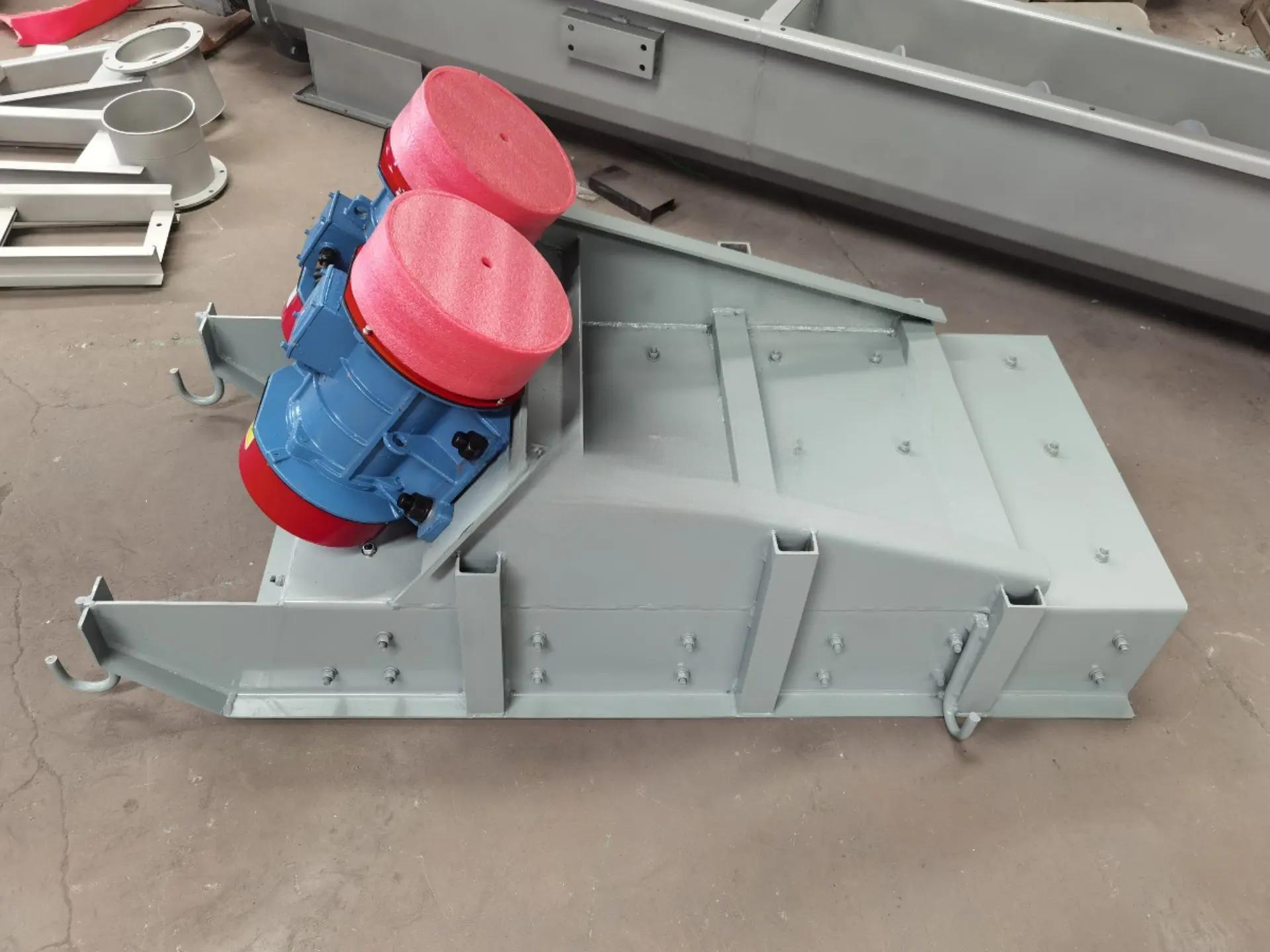

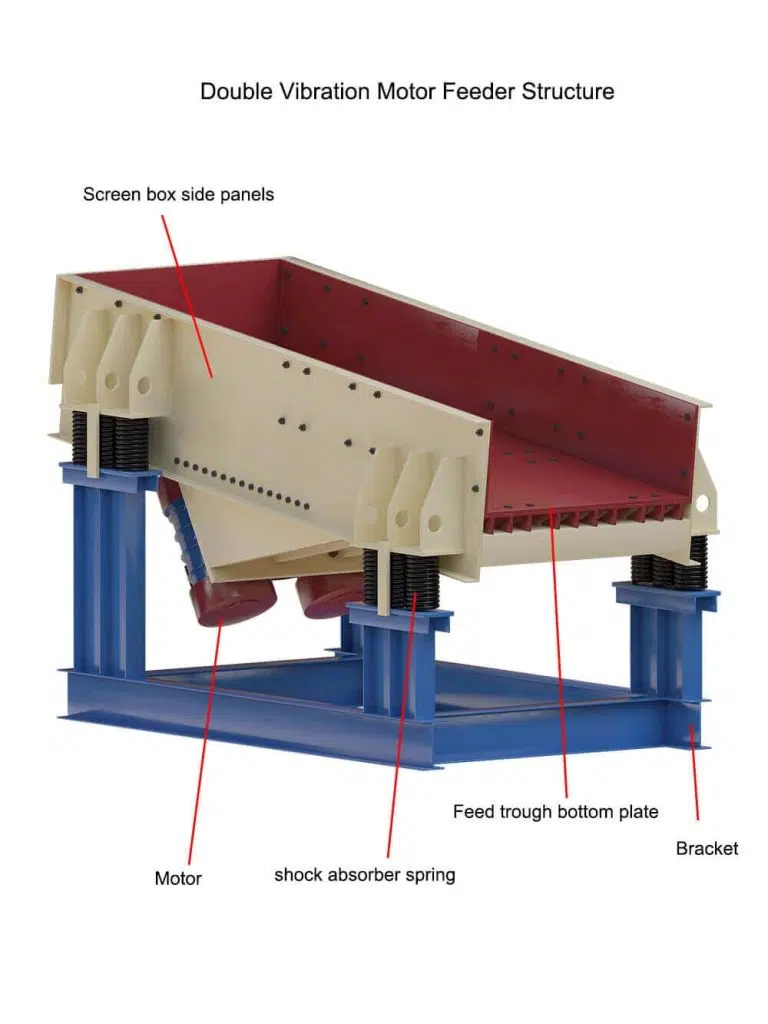

GZG series motor vibrating feeder conveyor drives the exciter through a vibration motor or two motors to make the feeding trough vibrate periodically in a straight line along the inclined direction. When the vertical component of the vibration acceleration of the feeding trough exceeds the gravity acceleration, the material in the trough is thrown up and jumps forward along a parabolic trajectory. The throwing and falling process of the material is completed quickly, and due to the continuous excitation of the excitation source, the feeding trough maintains continuous vibration, and the material in the trough continuously jumps forward, realizing stable transportation and feeding of the material.

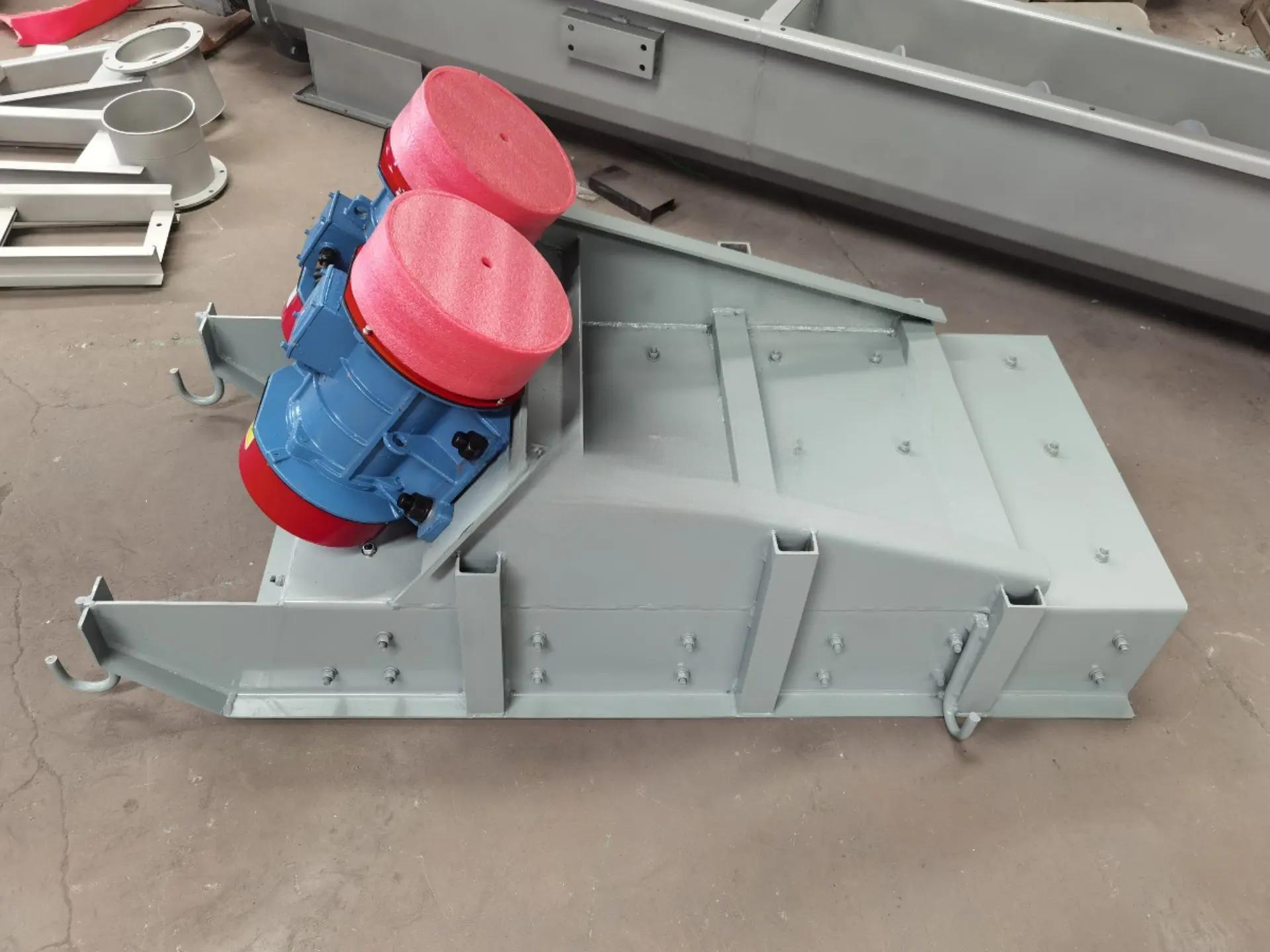

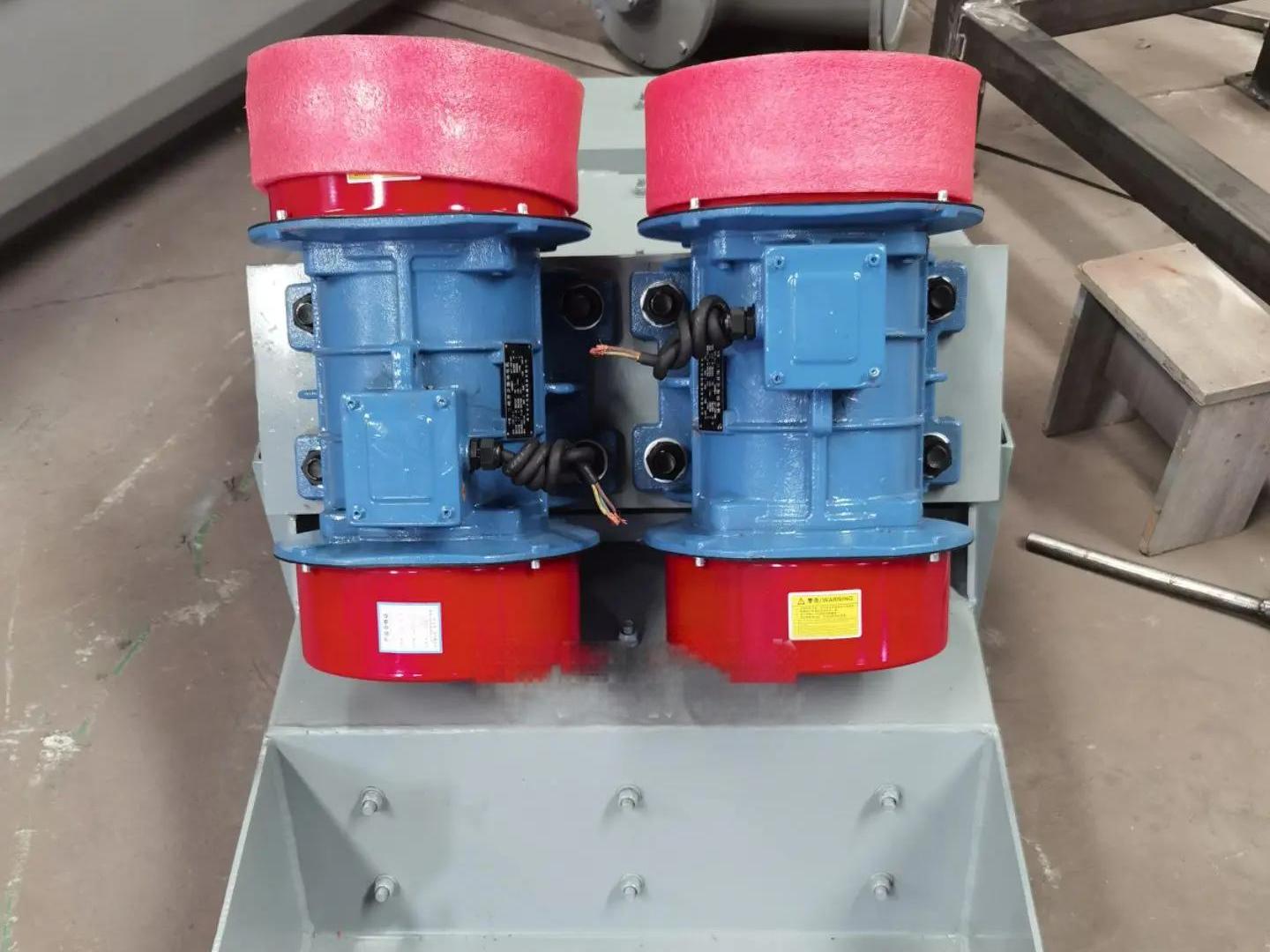

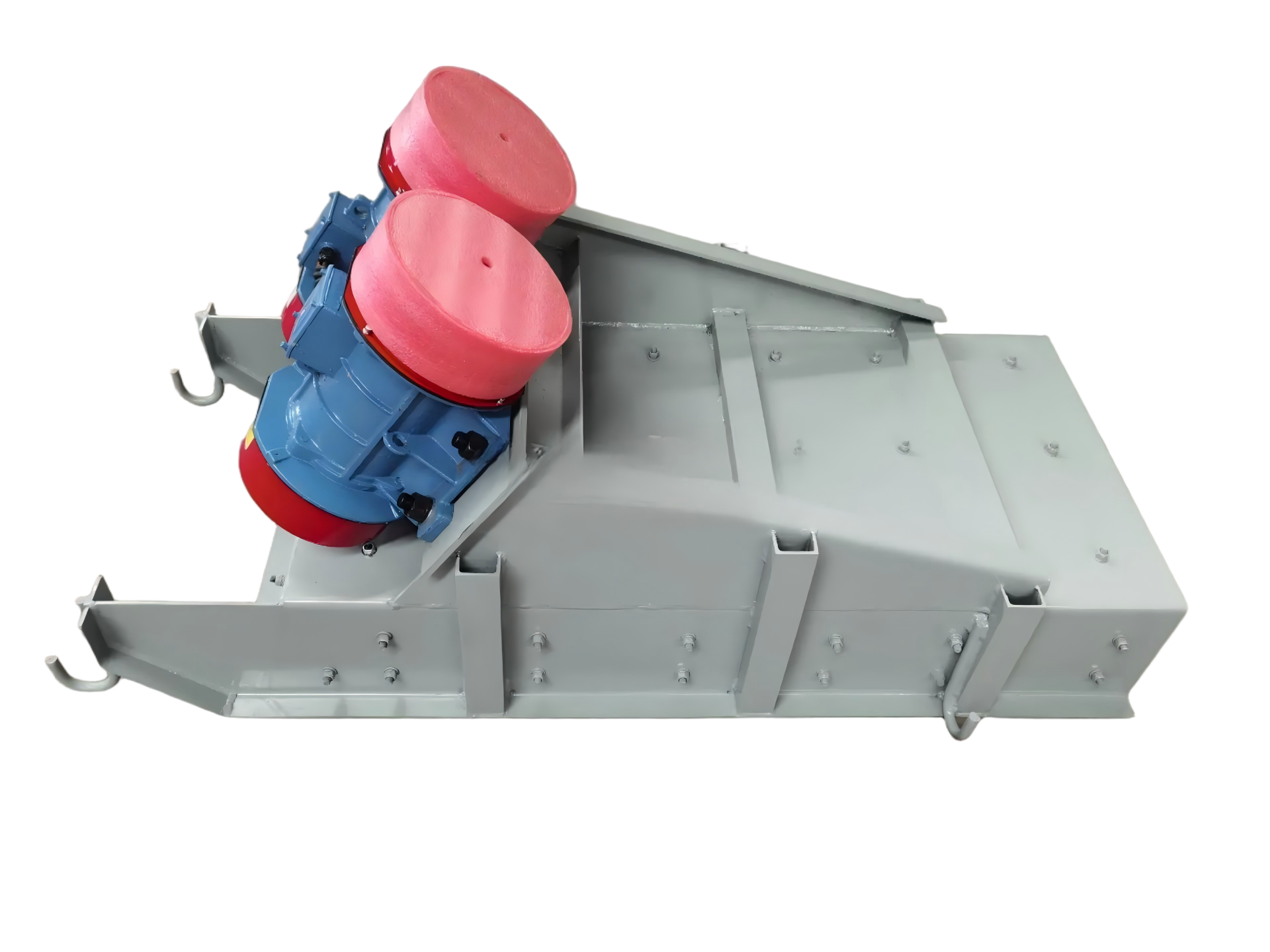

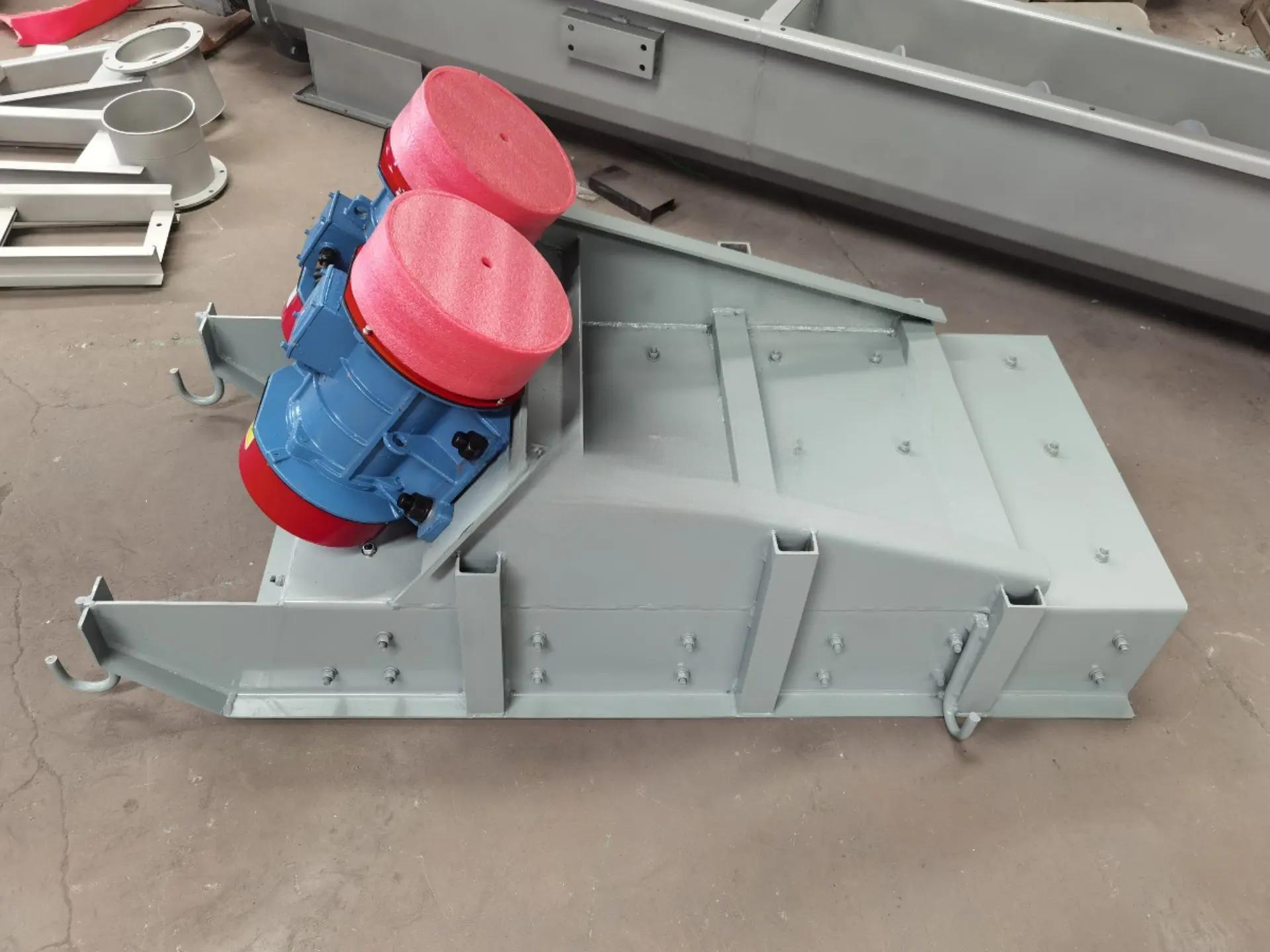

GZG vibrating feeder is mainly composed of feeding trough, exciting motor, motor base, main vibration spring, vibration isolation spring, etc. The following are the functional characteristics of each component:

Trough: Carrying and conveying materials, directly in contact with materials. The trough body is designed to be smooth, reduce material residue, and facilitate cleaning and maintenance.

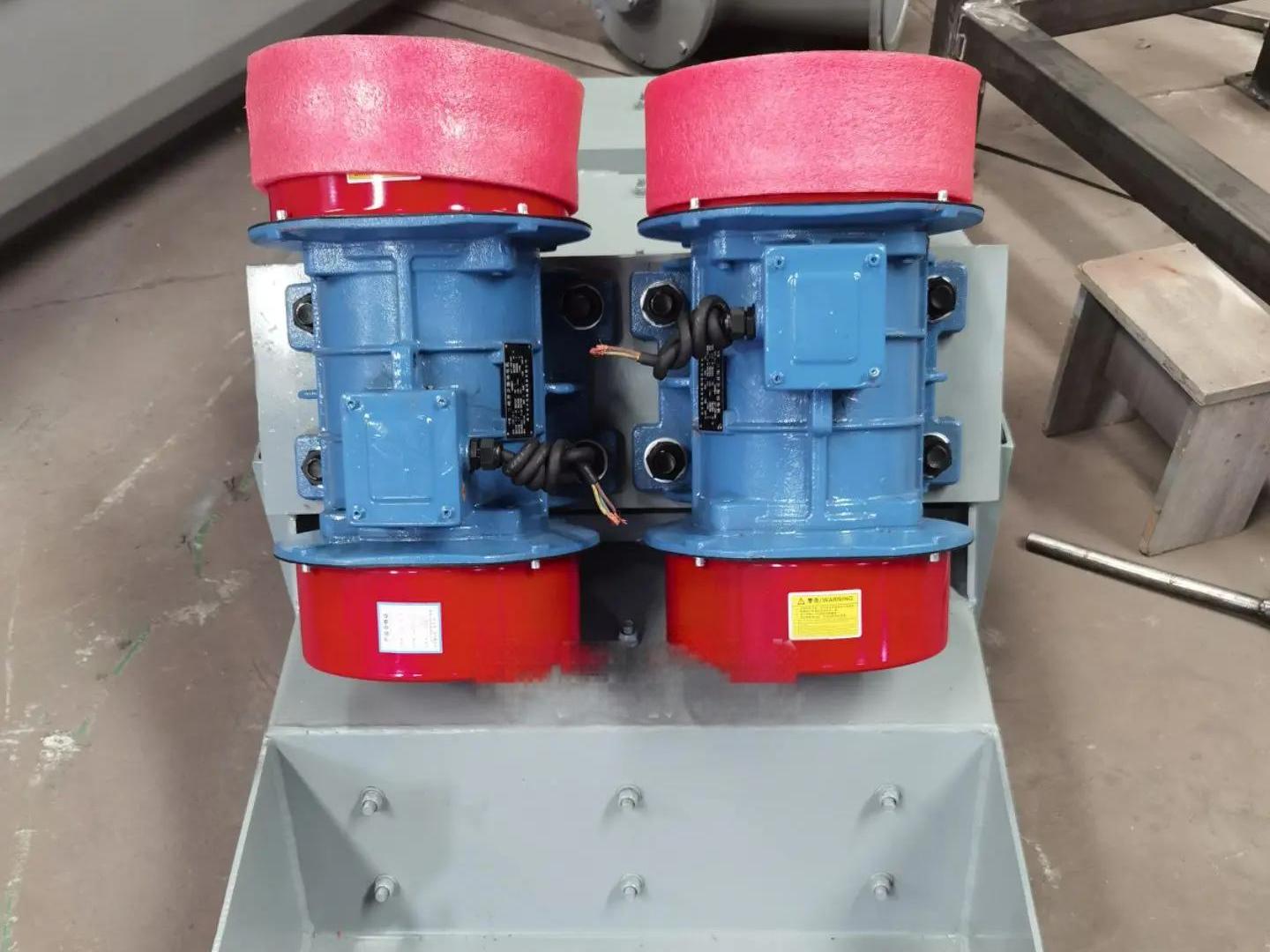

Vibration Motor: Provides vibration force, drives the feeding trough to vibrate, and realizes material transportation. The exciting force is adjustable, the operation is smooth, and the energy consumption is low. It is suitable for dusty environments and has overheating protection function.

Motor Base: Fixes the exciting motor to ensure stable connection with the feeding trough. It has a vibration reduction effect.

Main Vibration Spring: Supports the feeding trough and transmits the vibration force of the exciting motor, so that the feeding trough produces directional vibration. It can withstand high-frequency vibration to ensure long-term stable operation of the equipment.

Vibration Isolation Spring: It has a good vibration isolation effect and reduces the impact of noise and vibration on the surrounding environment. Made of high-quality rubber or spring steel, it is wear-resistant and aging-resistant, and can effectively extend the service life of the equipment.