- output:1-20t/h

- Feed size:<10

- Motor power:1.5-7.5kw

Jigging machine uses water as mineral media,belong to deep tank separation process,which can separate mineral ore from gangue according to difference of weight proportion.Diaphragm,stroke and frequency of stroke can adjust flexibly,and it is used for tungsten,tin,sand gold,hematite,magnetite,manganese,titanium,antimony,lead and niobium gravity process.

| 型号 Model | 跳汰室(个) Jigging chamber(pcs) |

最大给矿粒度 Feed size(mm) |

冲程 Stroke(mm) |

冲次 Time/min |

处理量 Capacity(t/h) | 功率 Power (kw) |

| JT-0.57 | 1 | 6 | 12,17,21 | 80-180 | 1-2.5 | 1.5 |

| JT1-1 | 1 | <10 | 12,17,21 | 80-180 | 2-3 | 2.2 |

| JT2-2 | 2 | <10 | 12,17,21 | 80-180 | 4-8 | 3 |

| JT3-1 | 1 | <10 | 10-47 | 50-125 | 6-10 | 5.5 |

| JT4-2 | 2 | <10 | 10-30 | 50-125 | 10-15 | 7.5 |

| JT5-2 | 2 | <10 | 15,20,25 | 50-125 | 12-20 | 7.5 |

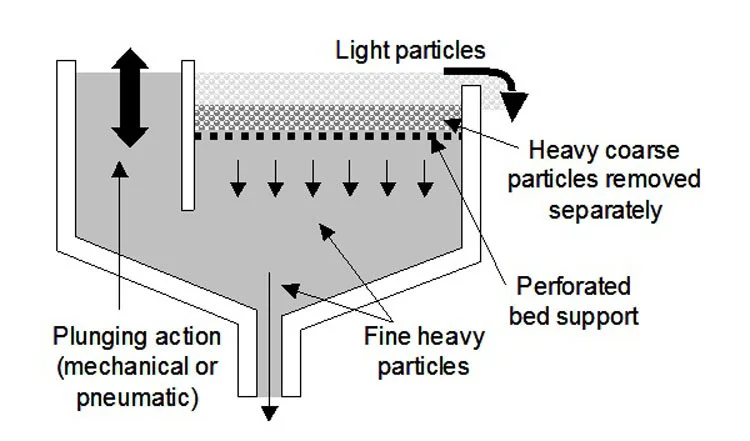

The operation of a jigging separator machine relies on two key processes: pulsation and stratification. Understanding this helps you see how simple yet effective the machine is.

Pulsation: The machine’s drive mechanism creates a repeated upward and downward movement of water through a screen bed. This can be done with a mechanical piston, a flexible diaphragm, or pulsed air. This creates the “jigging” action.

Stratification: As your feed material (crushed ore) is introduced onto the screen, the upward pulse of water lifts all the particles. As the water pulse recedes, the particles settle back down. The densest mineral particles sink fastest and deepest into the bed. Lighter waste particles settle more slowly and remain on top.

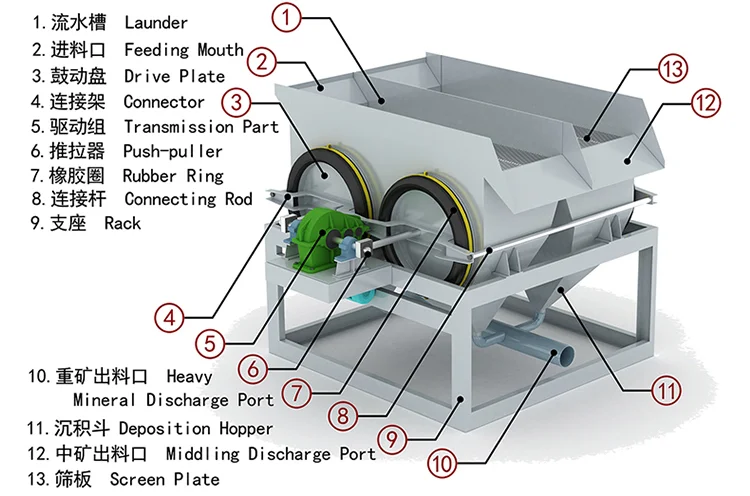

The sawtooth-wave trapezoidal jig features a monolithic structure, primarily consisting of the tank body, screen frame, screen mesh, springs, diaphragm, movable cone hopper, electromagnetic variable-speed motor, reduction gearbox, and transmission mechanism.

Advantages

The jig concentrator stands out for its efficient and economical operation, requiring significantly less water compared to most centrifugal concentrators, making it ideal for resource-sensitive environments. It delivers exceptional mineral recovery rates, efficiently converting 0.5% to 30% of feed material into high-grade concentrate, maximizing both yield and profitability. Offering wide feed adaptability (up to 30mm particle size), the jig concentrator reduces the need for pre-screening and minimizes over-grinding, optimizing gravity recovery while lowering energy consumption. With its low operating costs, minimal water usage, and high recovery performance, it is a cost-effective and versatile solution for both small and large-scale mineral processing operations.

✔ Wide Particle Size Range(0.5-50mm)

✔ No Chemical Additives(Eco-friendly separation)

✔ Low Energy Consumption(Up to 30 t/h per unit)

✔ High Recovery Rates(85-95% for gold ore)