- output:3.1-220m³/h

- Feed size:Overflow size20-120μm

- Motor power:/

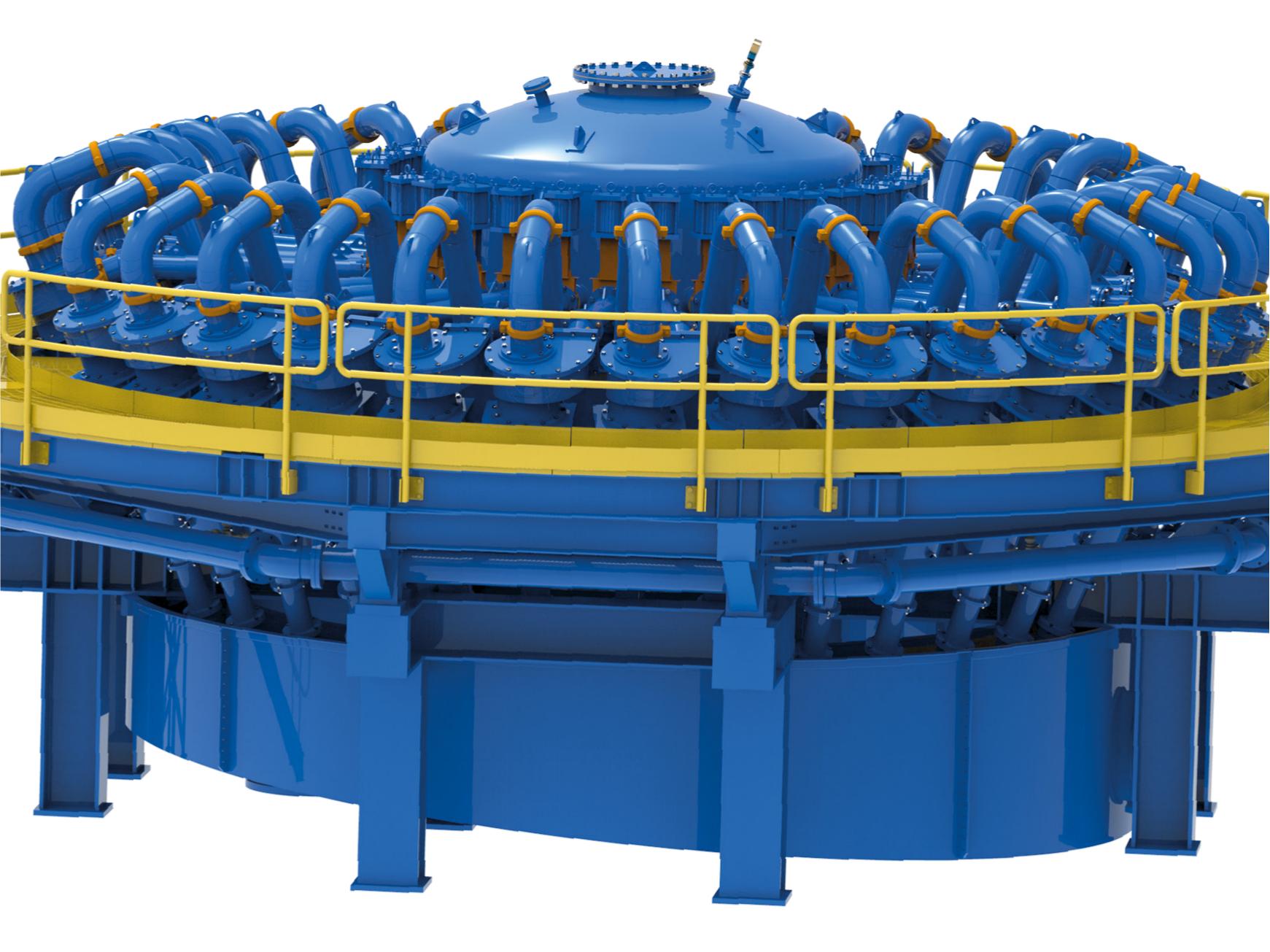

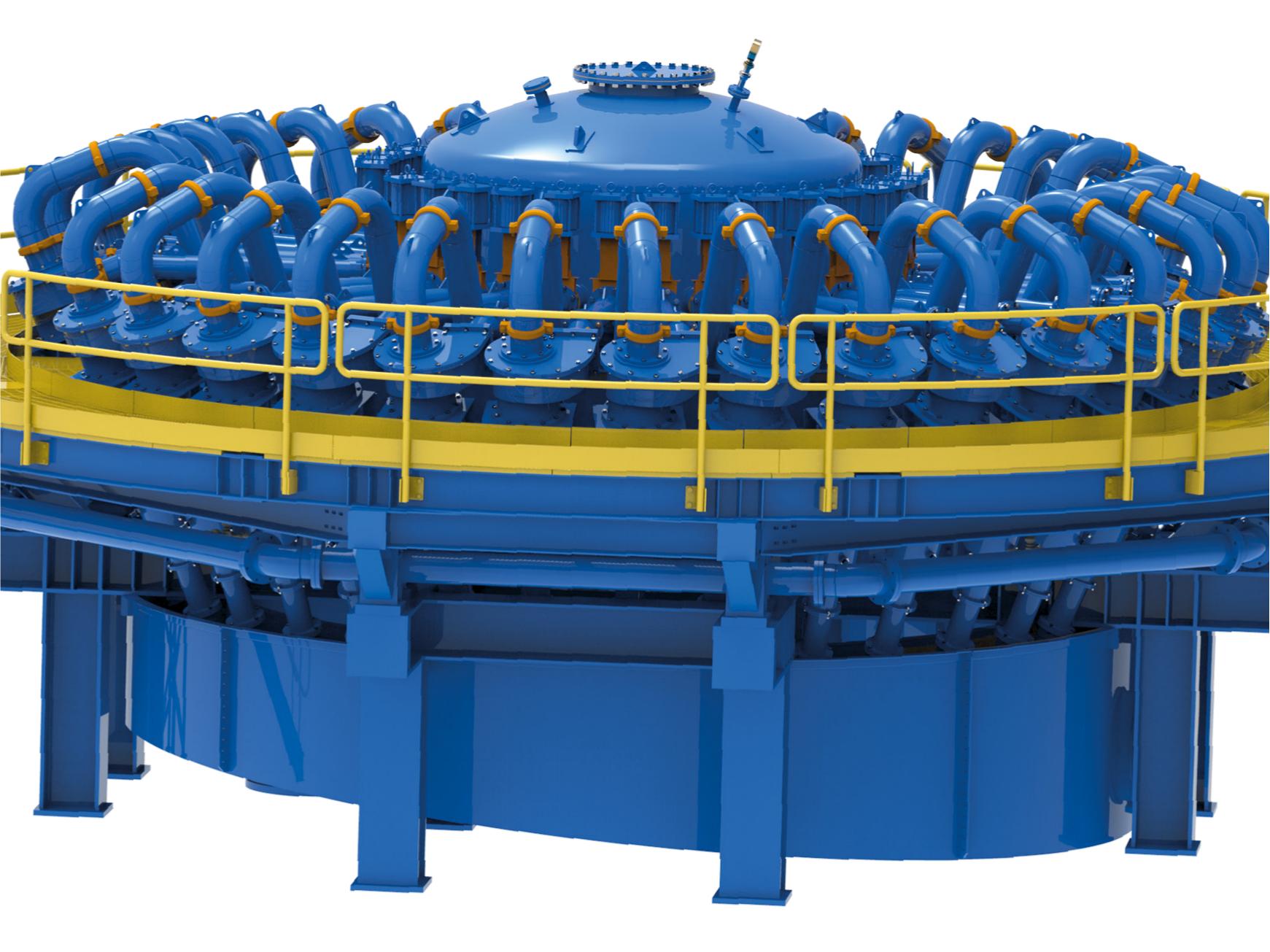

Hydro-cyclone classifies coarse and fine materials by centrifugal force.Materials are fed by pressure,so more power is needed.However,it have advantages of low cost, small covering space,high classifying ratio and large capacity.It is mainly used as the classifying equipment in the second milling process.

| 型号 Model | 直径 Diameter(mm) | 锥角(°) Cone angle | 溢流粒度(μm) Overflow size | 处理能力 Capacity(m³/h) | 重量(kg) Weight |

| FX-125 | 125 | 20 | 20-50 | 3.1-6.1 | 57 |

| FX-150 | 150 | 20 | 35-75 | 7.5-15 | 128 |

| FX-250 | 250 | 20 | 40-100 | 10-39 | 205 |

| FX-300 | 300 | 20 | 45-105 | 37-43 | 287 |

| FX-350 | 350 | 20 | 50-110 | 74-90 | 430 |

| FX-500 | 500 | 20 | 60-120 | 170-220 | 718 |

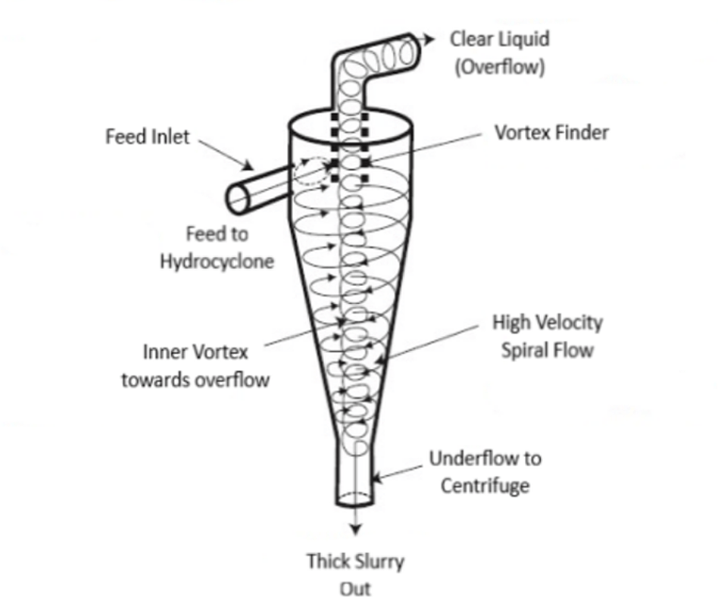

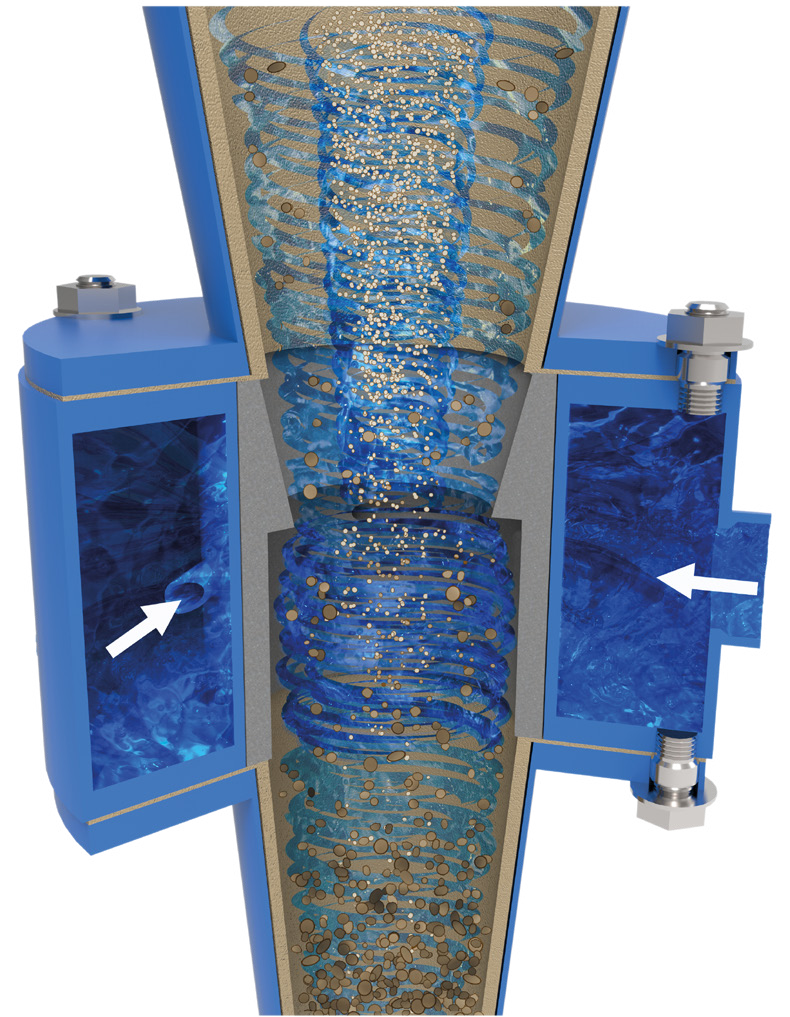

Fluid carries the suspended particles, enters the hydrocyclone tangentially, spirals downward and produces a centrifugal field in free vortex flow. Larger particles then move to the outside of the hydrocyclone in a spiral motion and due to the fraction, the liquid goes out through the spigot. Due to the limited area of the spigot, an inner vortex, rotating in the same direction as the outer vortex but flowing upward, is established and leaves the hydrocyclone through the vortex finder, carrying most of the liquid and finer particles with it.

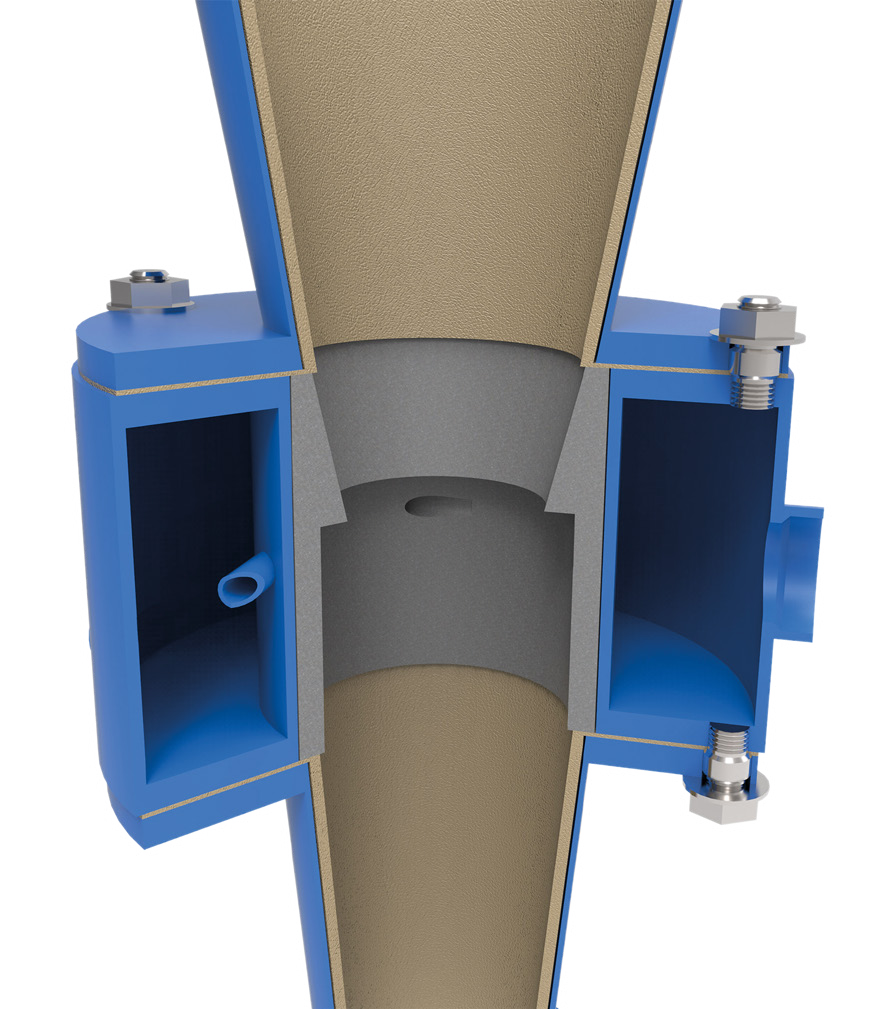

Cyclones are composed of four main components: the feed chamber, the cone (body), the underflow (spigot liner or apex), and the overflow (vortex finder). The feed chamber directs the slurry into a spiral flow, generating a vortex. The cone (body), which can be a single piece or multiple pieces, allows the material to continue to spiral, generating a centripetal force that pushes coarse material outwards, allowing fine particles and most of the water to move upward in a vortex.