- output:60t/h

- Feed size:100mm

- Motor power:75KW

Vertical shaft sand making machine is commonly used in crushing production line and sand production line, and it has been widely used in building sand,stone and various metallurgical slag crushing production line, etc.It is also widely used in mineral processing,coal,building materials,chemicals,refractories,metallurgy, cement,glass,ceramics,and electric power industries for the secondary and tertiary crushing production line.

| 型号规格Model | 800 | 1000 | 1250 | 1500 | 1750 | |

| 转子直径Rotor diameter (mm) | 650 | 800 | 1000 | 1250 | 1560 | |

| 筒体高度Barrel height(mm) | 800 | 850 | 850 | 1000 | 1410 | |

| 主轴转速Main shaft speed(r/min) | 1350 | 970 | 740 | 650 | 600 | |

| 给料粒度Input size(mm) | 50 | 70 | 100 | 100 | 100 | |

| 出料粒度Output size(mm) | 0-5 | 0-5 | 0-5 | 0-5 | 0-5 | |

| 生产能力Capacity(t/h) | 5-15 | 10-30 | 20-60 | 30-80 | 40-100 | |

| 电机Motor- | 功率power(kw) | 30 | 55 | 75 | 110 | 132 |

| 转速shaft speed(r/min) | 1440 | 1440 | 750 | 750 | 750 | |

| 外形尺寸Overall dimension(mm) | 2200×860×1980 | 2700×1160×2000 | 2800×1400×2730 | 3100×1900×2300 | 3350×2100×2800 | |

| 重量Weight(tons) | 2.3 | 4.5 | 9.73 | 18.1 | 26.61 | |

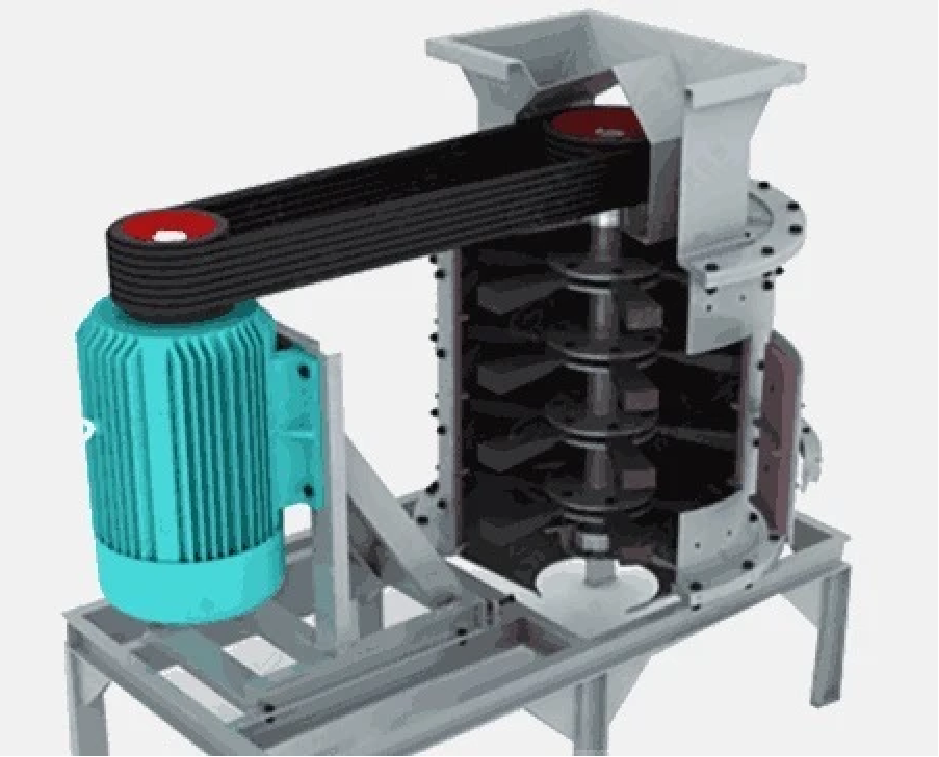

The stone falls vertically into the machine body from the upper part of the vertical shaft compound crusher and falls onto the equipment's throwing plate. Under centrifugal force, the material is thrown to the inner wall of the cylinder and violently collides with the counterattack plate installed on the inner wall. Violent impact also occurs, and the material is broken or cracked. After the material enters the conical rotor cavity, it is broken by stamping, extrusion, etc., during the falling process. The material is further broken into small particles, and the qualified finished product is discharged from the discharge port.

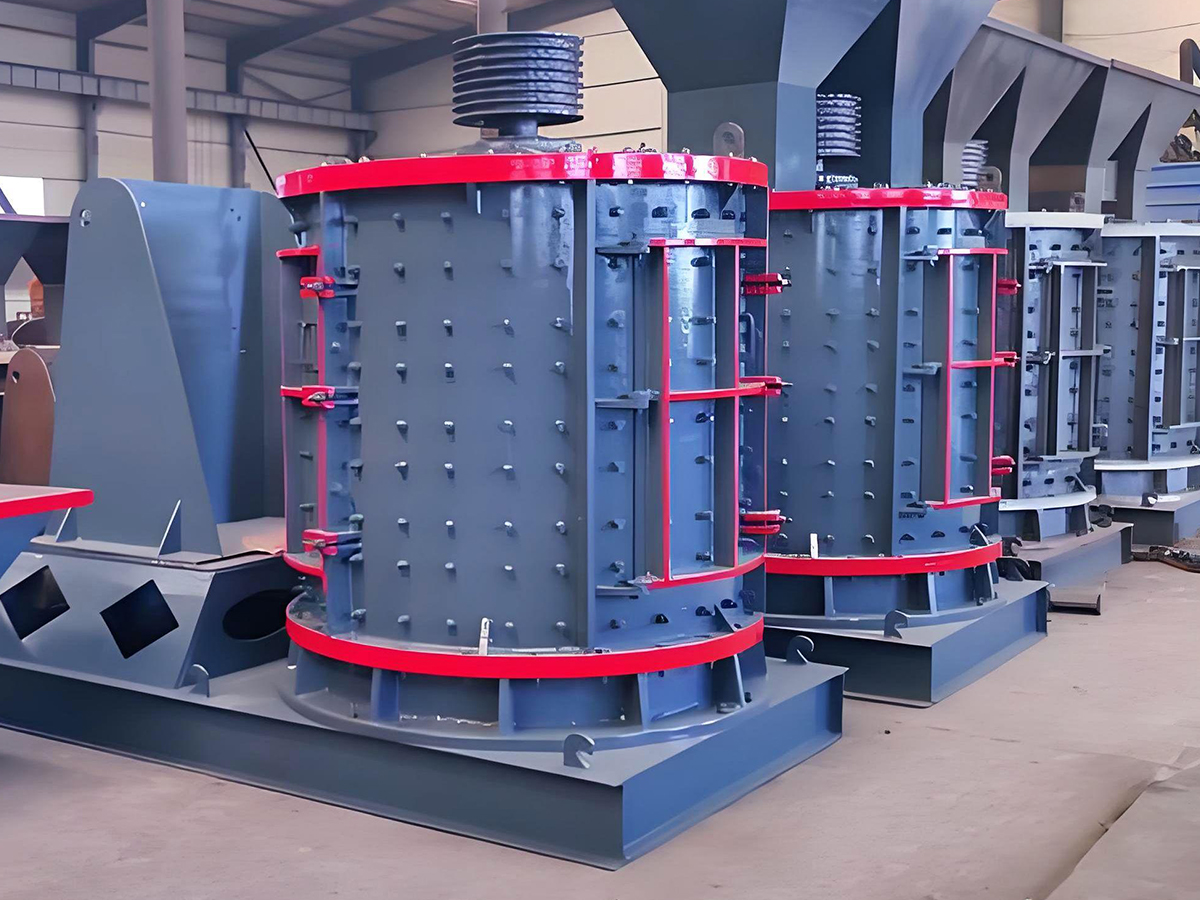

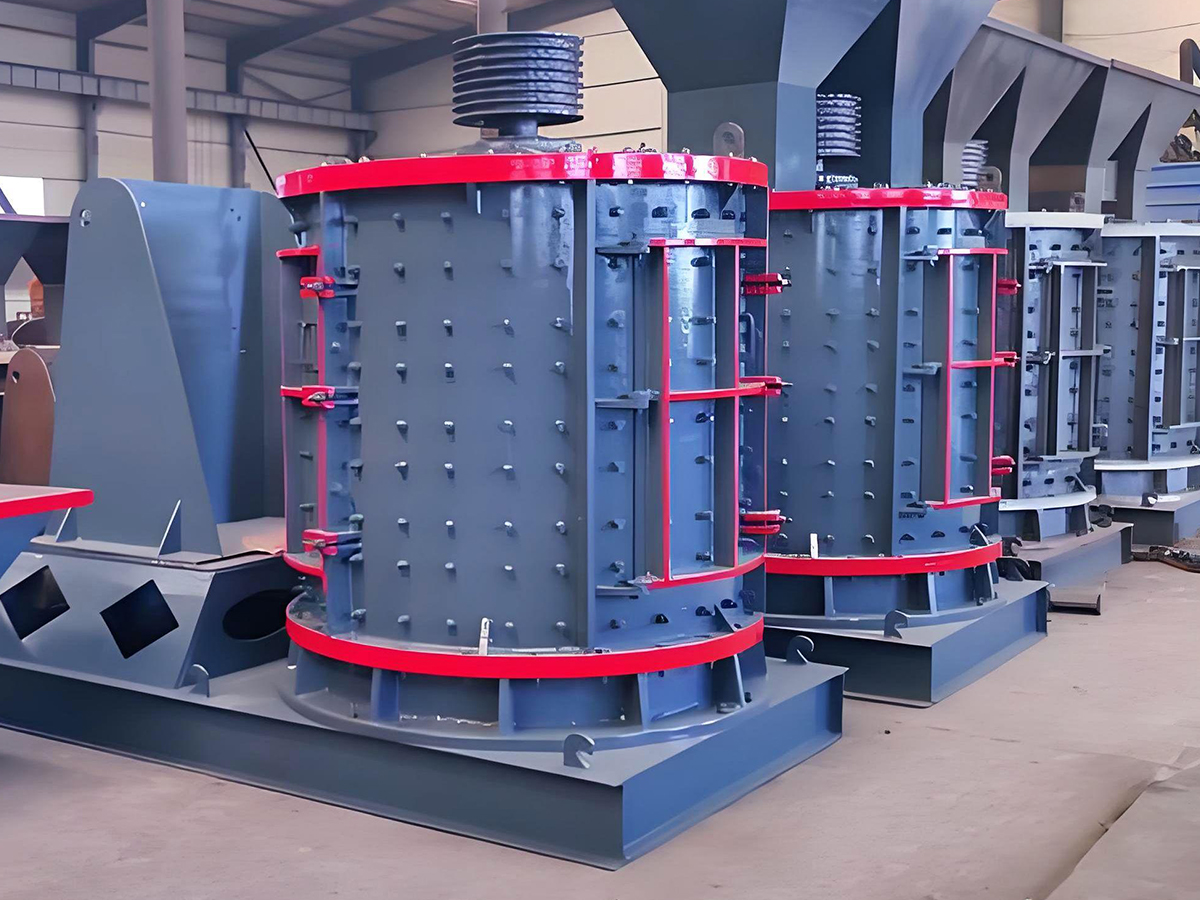

Vertical shaft compound crusher, also called vertical shaft sand-making machine, consists of a transmission device, bearing, upper machine cover, liner, hammer head, hammer plate, main shaft, belt, feed port, discharge port, support, motor, and access door, cylinder, upper cover, and base, etc., the internal structure is simple and reasonable, the operating cost is low, and the principle of stone against stone is used to reduce wear and tear.

优势AdvantagesSmall footprint:

The vertical compound crusher adopts a vertical structure. Compared with other crushing equipment, it occupies a smaller area and is more suitable for smaller work sites.

Low energy consumption: This equipment adopts advanced power configuration and crushing technology. Compared with other crushing equipment, it consumes less energy and is more economical.

Low noise: The vertical compound crusher adopts precision manufacturing technology and noise-absorbing materials, which can significantly reduce the noise of the equipment and improve the comfort of the working environment.

Uniform particle size: This equipment adopts multi-stage crushing and multi-stage screening technology to obtain finished materials with relatively uniform particle size distribution.

Wide scope of application: Vertical compound crushers are widely used for crushing and shaping materials in mining, metallurgy, construction, the chemical industry, cement, and other industries.