Mobile sand making plant is made up of the vibrating screen,belt conveyor,sand making machine,motor and control box and so on,this machine can eliminate the crushing area,environment,basic configuration for the client crushing work barriers,reduce the cumbersome infrastructure installation process and time consuming, and truly provide customers with convenient,efficient,low cost of crushing equipment.

主要技术参数Main technical parameters

| 项目Item | NS1848VS18518 | NS1860VS19526 |

| 运输长度Transport length(mm) | 14200 | 14200 |

| 运输宽度Transport width(mm) | 3000 | 3000 |

| 运输高度Transport height(mm) | 4500 | 4500 |

| 最大长度Maximum length(mm) | 14920 | 14920 |

| 最大宽度Maximum width(mm) | 3660 | 3660 |

| 最大高度Maximum height(mm) | 7100 | 7100 |

| 轮胎配置Tire configuration | Two axis | Three axis |

| 破碎机型号Model number of Crusher | VSI 8518 | VSI9526 |

| 最大进料粒度The largestfeed size(mm) | 40 | 40 |

| 处理量Processing capacity (t/h) | 200-260 | 300-380 |

| 振动筛型号Screen type | 3YK1848 | 3YK1860 |

| 主皮带机型号Main belt type | B800×7.5m | B800×8.5m |

| 发电机组型号(选配) Type of generator set(optional)(kw) |

300 | 600 |

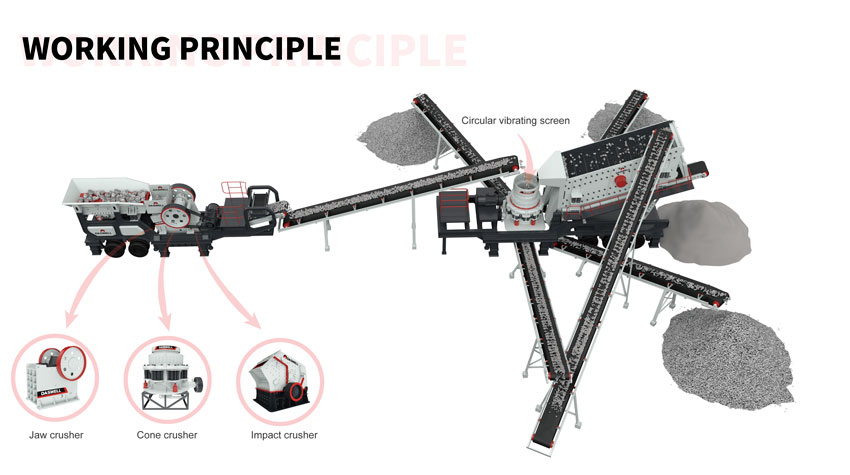

The main crusher machine of the mobile crushing plant can be a jaw crusher, an impact crusher, or a cone crusher. The material is evenly transported to the crusher through the feeder. After being initially crushed by the crusher, a circular vibrating screen forms a closed-circuit system to realize the cyclic crushing of the material. Materials that meet the particle size requirements are output by the belt conveyor to achieve production purposes.

The mobile crushing plant can also remove the circular vibrating screen according to actual production needs, directly crush the materials initially, and then cooperate with other crushing equipment to perform specific operations, which is convenient and flexible.

1Feeding: The large bulk material is loaded into the vibrating feeder.

2Primary crushing: The mobile jaw crusher crushes the large chunks.

3Secondary crushing: The crushed material is passed to an impact crusher or cone crusher for medium crushing and fine crushing.

4Screening: The vibrating screen sorts materials by size, sending qualified ones to the conveyor and returning the unqualified materials for further crushing, forming a closed-loop system.

5Output: The qualified finished aggregate is discharged from the belt conveyor.

优势Advantages

Mobility: can be easily moved to different construction sites for maximum flexibility.

High efficiency: powerful crushers and screens are designed to achieve high output.

Cost-effective: no need to transport raw materials, reducing operating costs.

Durability: with a sturdy structure to withstand harsh working environments.

Versatility: Suitable for a wide range of crushing processes from primary to tertiary.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine