- output:120t/h

- Feed size:200mm

- Motor power:

The mobile impact crushing station for sale is mainly used for metallurgy, chemical industry, building materials, hydropower, and other materials that often require relocation operations, especially for the operations of mobile stone such as highways, railways, and hydropower projects. Users can choose according to the types of raw materials to be processed. Different scales and finished material requirements adopt a variety of configuration forms.

| 项目Item | NS1848F1210 | NS1860F1214 | NS2160F1315 |

| 运输长度Transport length(mm) | 12600 | 13800 | 13800 |

| 运输宽度Transport width(mm) | 3000 | 3000 | 3000 |

| 运输高度Transport height(mm) | 4500 | 4500 | 4500 |

| 最大长度Maximum length(mm) | 14730 | 14860 | 14880 |

| 最大宽度Maximum width(mm) | 3620 | 3660 | 3910 |

| 最大高度Maximum height(mm) | 6680 | 7100 | 7200 |

| 轮胎配置Tire configuration | Two axis | Three axis | Three axis |

| 破碎机型号Model of Crusher | PF1210 | PF1214 | PF1315 |

| 最大进料粒度The largest feed size(mm) | 200 | 200 | 300 |

| 处理量Processing capacity(t/h) | 80-120 | 120-180 | 150-250 |

| 振动筛型号Screen type | 3YK1848 | 3YK1860 | 3YK2160 |

| 主皮带机型号Main belt type | B800×7.5m | B800×8.5m | B1000×8.5m |

| 发电机组型号(选配)Type of generator set(optional)(kw) | 300 | 400 | 600 |

The material is evenly fed into the crushing chamber by the feeder. Driven by the high-speed rotating rotor, it is subjected to high-speed impact from the hammers and thrown against the impact plate to achieve secondary crushing. The crushed material is repeatedly impacted and sheared in the chamber until it reaches the required particle size and is discharged from the bottom. The entire system can be hydraulically adjusted to precisely control the particle shape and size of the finished product.

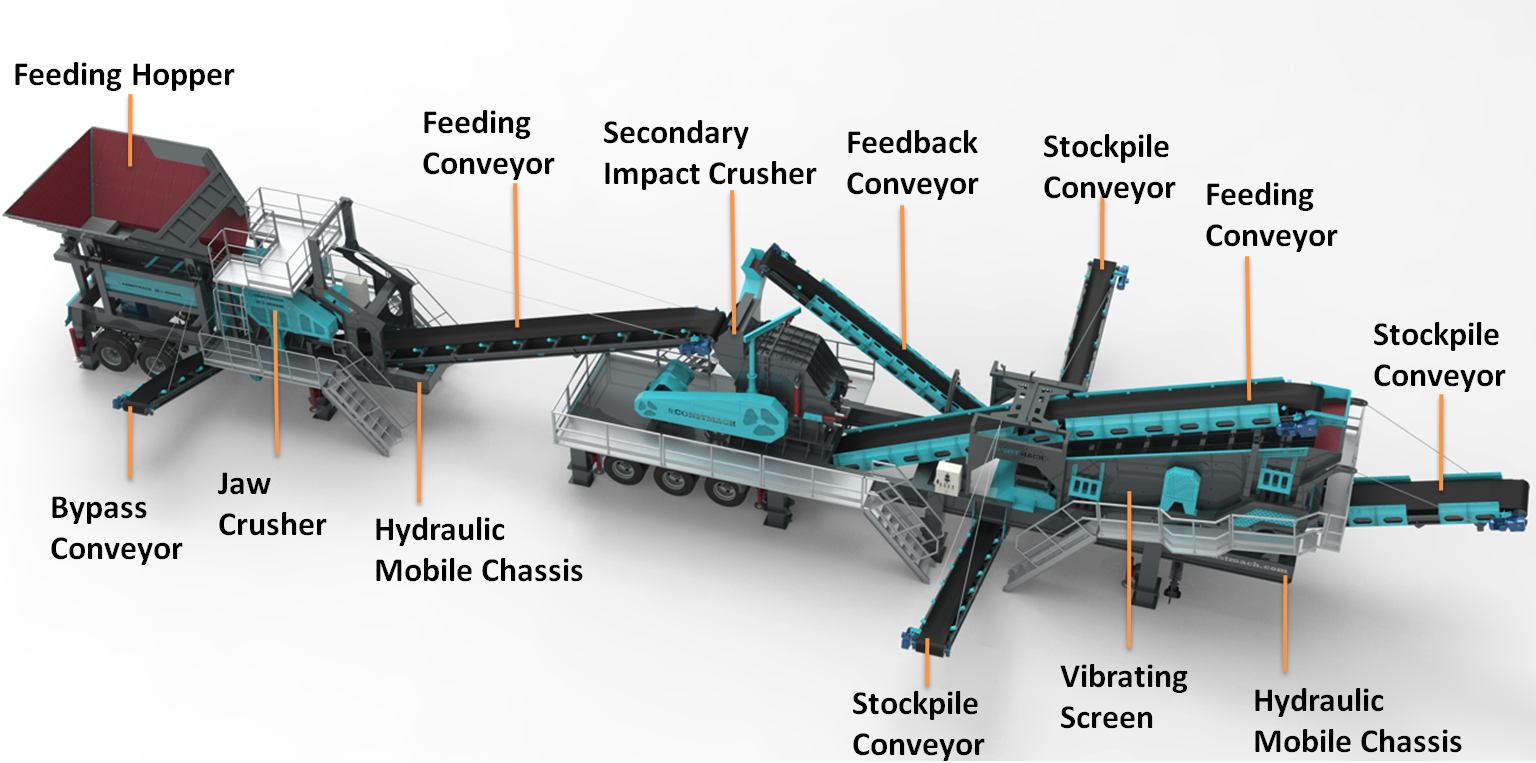

structure of portable impact crusher

Feeding System: Vibrating feeder with pre-screening function to remove fine materials and improve crushing efficiency.

Main crusher (impact crusher): Heavy-duty rotor + high wear-resistant hammers + adjustable impact plates.

Power and hydraulic system: Diesel engine, diesel-electric hybrid, or fully electric drive, selected according to working conditions.

Screening system (optional): Double or triple screens for one-time forming of high-quality aggregates.

Conveying system: Flexible configuration of main discharge belt, return belt, and side discharge belt.

Intelligent control center: PLC touch screen, load adaptive control system, safety interlock design.

Mobile chassis: Tracked (high mobility) or wheeled (convenient transportation).

优势Advantages

for larger feed particle size, higher capacity, and better product particle shape. Reasonable configuration, smooth process, high production efficiency, and good product particle shape. The standard modular design of the cavity liners and toothed impact plates ensures strong interchangeability, higher utilization rate, and longer service life.

Hydraulic control offers flexible applications

Hydraulic drive controls track movement, equipment installation, and production operations, resulting in smoother transmission, stepless speed regulation, greater flexibility, and better controllability. Depending on different customer needs, various configurations are available, including full hydraulic and hydraulic + grid-connected power options, allowing for flexible combinations and cost control. The main equipment comes standard with a hydraulic opening and closing mechanism or is equipped with a dedicated lifting tool for replacing the hammer, offering flexible application and easy operation.

Diverse Equipment

Depending on the different processing needs of customers, the sand making production line can be configured in a variety of ways. It can be used as a single machine or in combination with multiple machines to achieve the combined production of crushing and screening functions. It can also be used in conjunction with other mobile crushing and screening stations.

Highly mobile and easy to relocate

This machine offers a variety of power drive options, providing high flexibility and maneuverability. No support legs or fixed foundations are required during operation. The complete set of equipment boasts strong performance, flexible and compact combinations, low site requirements, and the ability to operate anywhere. Its compact structural design, small turning radius, and convenient and quick entry and exit from the site facilitate easy relocation.