Spiral chute is highly efficient equipment for gravity separation.It is commonly used in rough and sweep separation process for iron,chromite,tin and tungsten beneficiation production.

| 型号 Model | 外径(mm) Outside diameter |

螺距(mm) Pitch of screw |

径距比 Rate | 倾斜角(°) Inclination | 头数 Number of threads |

围数 Number of turns |

给矿粒度(mm) MaxFeed size | 给矿浓度(%) Mine density |

生产能力 Capacity(t/h) | 占地面积 Area(m³) | 高度 Height(m) |

| DL400 | 400 | 180 | 0.45 | 9 | 1-2 | 4-5 | 0.02-0.2 | 30-50 | 0.2-0.5 | 0.25 | 1.5 |

| DL600 | 600 | 390/360 | 0.4 | 9 | 1-2 | 4-5 | 0.02-0.2 | 30-50 | 0.8-1.2 | 0-0.5 | 2.6 |

| DL900 | 900 | 540/360 | 0.4/0.6 | 9 | 2-3 | 4-5 | 0.03-0.3 | 30-50 | 2-3 | 1.2 | 4 |

| DL1200 | 1200 | 720/540 | 0.6 | 9 | 2-4 | 4-5 | 0.03-0.3 | 30-50 | 4-6 | 2 | 5.23 |

| DL1500 | 1500 | 900 | 0.6 | 9 | 2-4 | 4-5 | 0.03-0.3 | 20-45 | 6-8 | 4 | 5.23 |

| DL2000 | 2000 | 1200 | 0.6 | 9 | 2-4 | 3-5 | 0.04-0.4 | 20-40 | 7-10 | 5.7 | 5.23 |

1.The sand pump sends the ore to the two feed inlets at the upper end of the screw, adding supplemental water to adjust the concentration of the ore pulp.

2.The ore pulp naturally swirls from high to downward, generating a kind of inertial centrifugal force in the rotating slope.

3.As the slurry flows down the spiral direction, minerals with high specific gravity move to the inner edge of the spiral while light materials move to the outer edge.

4.According to the differences in the specific gravity, particle size, and shape of the ore, the ore and sand are separated by the gravity and centrifugal force of the swirling flow.

5.The concentrates flow into the concentrate bucket. The tailings flow into the tailing bucket and then they are discharged with the sand pump, completing the process of dressing.

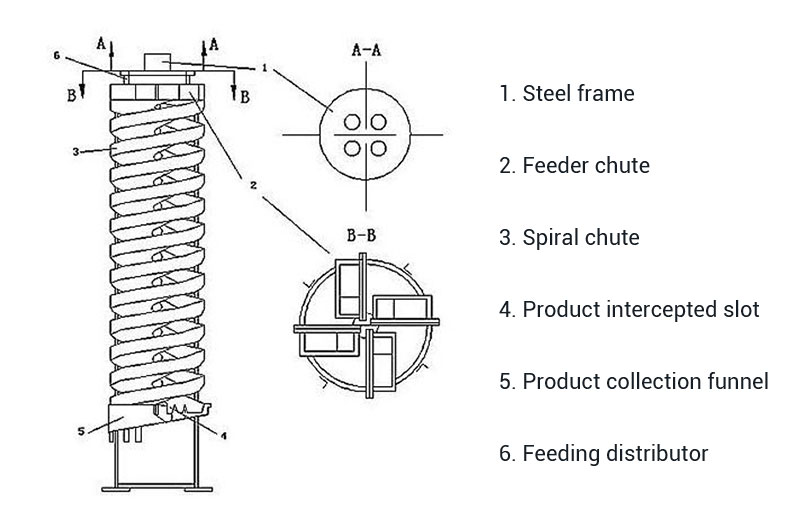

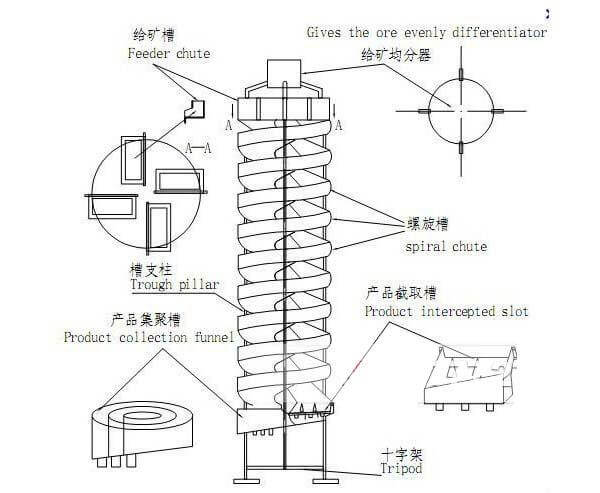

The spiral chute parts have a distributor and feed chute in the upper part and a product interceptor and collection chute in the lower part. The entire equipment is framed vertically with steel frames.

Advantages

The PU spiral chute separator offers significant advantages for mineral processing through its efficient gravity-based separation technology. Combining cost-effectiveness with environmental sustainability, these lightweight yet durable chutes feature moisture-proof, rust-resistant, and corrosion-proof properties, ensuring extended service life with minimal maintenance requirements. Their simple gravity-powered operation eliminates the need for complex mechanical structures or additional power equipment, making them both energy-efficient and eco-friendly while avoiding chemical use or pollution generation. The optimized spiral design enhances material flow dynamics to achieve superior separation performance, consistently delivering improved recovery rates and higher mineral grades – all while maintaining exceptionally low operational costs.

✔ Extended Lifespan – PU material resists abrasion & impact, lasting 3–5 times longer than fiberglass.

✔ High Recovery Rate – Effective for 0.02–2mm particles, especially fine precious metals (e.g., gold, tungsten, titanium).

✔ Zero Maintenance – No power or moving parts—separation relies solely on gravity and spiral flow dynamics.

✔ Corrosion Resistance – Handles acidic/alkaline ores & seawater processing without degradation.

✔ Modular Design – Can be arranged in single or multi-unit setups, adapting to throughputs of 0.5–10 t/h.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine