- output:0.2-8t/h

- Feed size:/

- Motor power:2.95-31.5kw

SF series flotation machine has function of inspiration,adsorption and flotation,which forms flotation circuit without any auxiliary equipment.This equipment is applied for rough and scavenging process of ferrous metal,precious metal and nonferrous metal.

| Model | Volume (m³) |

Impeller diameter (mm) | Capacity (t/h) |

Power of motor (Kw) |

Chute weight (kg) |

Single chute overall dimension (mm) |

|

| Stirring motor | Scraper motor | ||||||

| SF0.37 | 0.37 | 300 | 0.2-0.4 | 2.2 | 0.75 | 445 | 700×700×750 |

| SF0.7 | 0.7 | 350 | 0.3-1.0 | 3 | 0.75 | 600 | 900×1100×950 |

| SF1.0 | 1 | 400 | 0.45-1.1 | 5.5 | 0.75 | 978 | 1000×1000×1000 |

| SF1.2 | 1.2 | 450 | 0.6-1.6 | 5.5 | 0.75 | 1240 | 1050×1050×1050 |

| SF2.0 | 2 | 550 | 1.5-3.0 | 7.5 | 1.1 | 1879 | 1400×1400×1150 |

| SF2.8 | 2.8 | 550 | 1.5-3.5 | 11 | 1.1 | 2242 | 1600×1600×1150 |

| SF4.0 | 4 | 650 | 2.0-4.0 | 15 | 1.5 | 2660 | 1900×2000×1200 |

| SF8.0 | 8 | 760 | 4.0-8.0 | 30 | 1.5 | 4043 | 2250×2850×1400 |

Flotation process refers to the flotation separation in mineral processing. In the flotation machine, the ore slurry treated with the added agent, by aeration and stir, some of the ore particles are selectively fixed on the air bubbles and floats to the surface of the slurry and is scraped out. The rest is retained in the pulp, thus achieve the purpose of separating different minerals. The complete froth flotation process in metallurgy consists of rougher flotation, concentrate flotation and scavenging flotation.

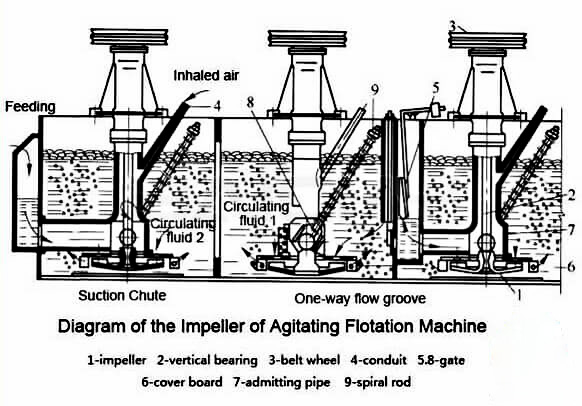

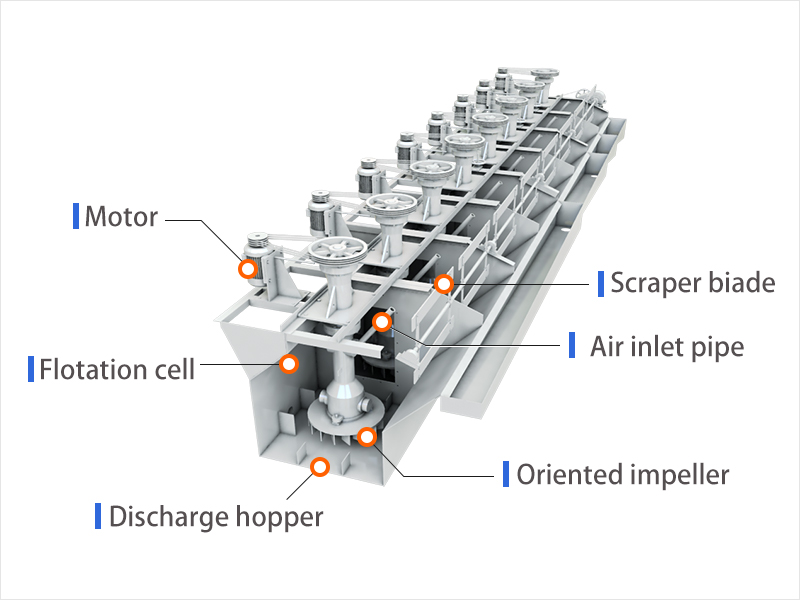

The structure of the SF flotation cell is mainly composed of the tank, impeller, motor, scraper and transmission device, etc. The volume of the SF flotation cell is more than 10m³.

Advantages

The SF Froth Flotation Machine incorporates several key design features:

Dual slurry circulation: Backward-inclined, double-sided blades facilitate efficient slurry circulation within the tank.

High suction capacity: A substantial clearance between the impeller and cover plate ensures optimal suction performance.

Reduced wear: The impeller operates at a low circumferential speed, extending the lifespan of wear components.

Efficient foam movement:

SF Flotation Cells Advantages:

Energy Efficient: Compared to traditional mechanical stirring flotation machines, our product can reduce energy consumption by 30-50%.

Enhanced Coal Quality: Our product delivers significantly higher separation accuracy and lower ash content in clean coal. Specifically, it can reduce ash content by 1-2% compared to conventional mechanical stirring flotation machines.