The fine sand recycling machine is a new type of environmental protection equipment, which effectively solves a large amount of fine sand lost by the sand washing machine in the traditional sand-making industry, which not only improves the quality of the sand but also reduces the disposal cost of the tailings.

主要技术参数Main technical parameters

| 型 号 M o d e l | 处理量Capacity(m³/h) | 分离器规格Separator size | 功率Power(kw) | 筛面尺寸Sieve size W×L(mm) | 筛板材质Sieve material | 重量Weight(kg) | 外形尺寸Overall size(mm) |

| NX250 | ≤60 | 250 | 13.2 | 900×1800 | 进口聚氨酯Imported polyurethane | 1460 | 3120×1300×272 |

| NX300 | ≤75 | 300 | 17.2 | 900×1800 | 进口聚氨酯Imported polyurethane | 1510 | 3120×1300×272 |

| NX350 | ≤100 | 350 | 20.7 | 900×1800 | 进口聚氨酯Imported polyurethane | 1700 | 3120×1300×2721 |

| NX550 | ≤120 | 250×2 | 26.4 | 1200×2400 | 进口聚氨酯Imported polyurethane | 2170 | 2630x1600×2773 |

| NX650 | ≤150 | 300×2 | 34.4 | 1200×2400 | 进口聚氨酯Imported polyurethane | 2500 | 3630×1600×2773 |

| NX750 | ≤200 | 350×2 | 41.4 | 1500×3000 | 进口聚氨酯Imported polyurethane | 2850 | 3630×1600×2773 |

| NX900 | ≤225 | 300×3 | 51 | 1800×3750 | 进口聚氨酯Imported polyurethane | 3500 | 4600×1900×2616 |

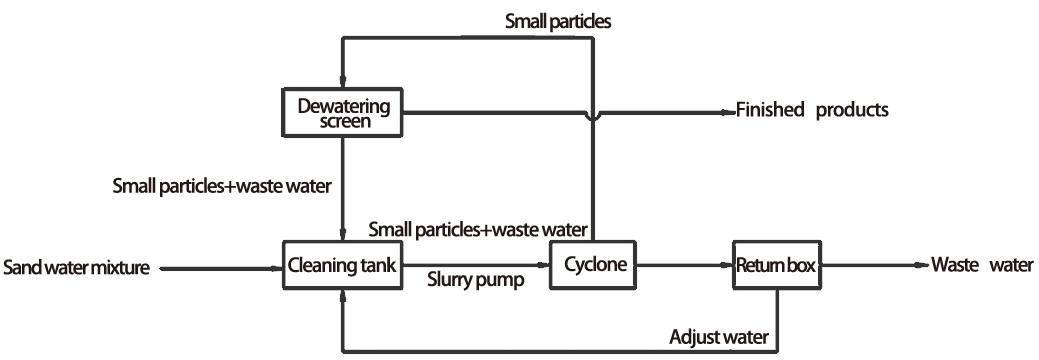

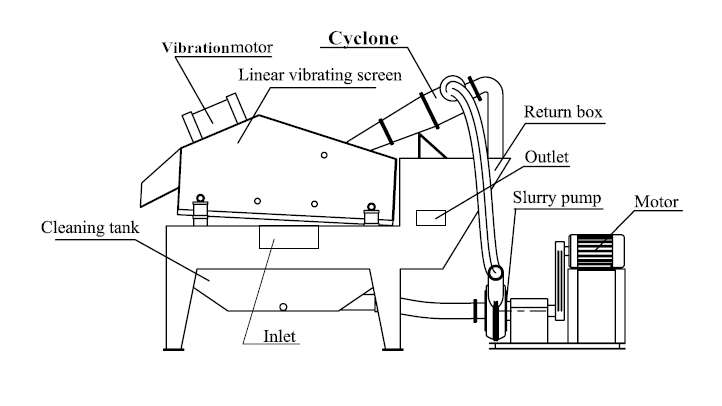

The pump sends the sand and water mixture to hydrocyclone, the fine sand with eccentricity is sent to vibrating screen. The fine sand and water are effectively separated after dehydration, and little fine sand and mud go back to washing trough. When the liquid surface of the washing trough is high, the fine sand discharges from output opening. The linear vibrating screen can recover material with concentration 70%-85%. Adjusting fineness modulus can be realized by changing pump rotation speed, changing pulp consistency, adjusting overflow water and changing sand sinking mouth. By the process above, the fine sand recovery system can finish three functions, cleaning, dehydration and grading.

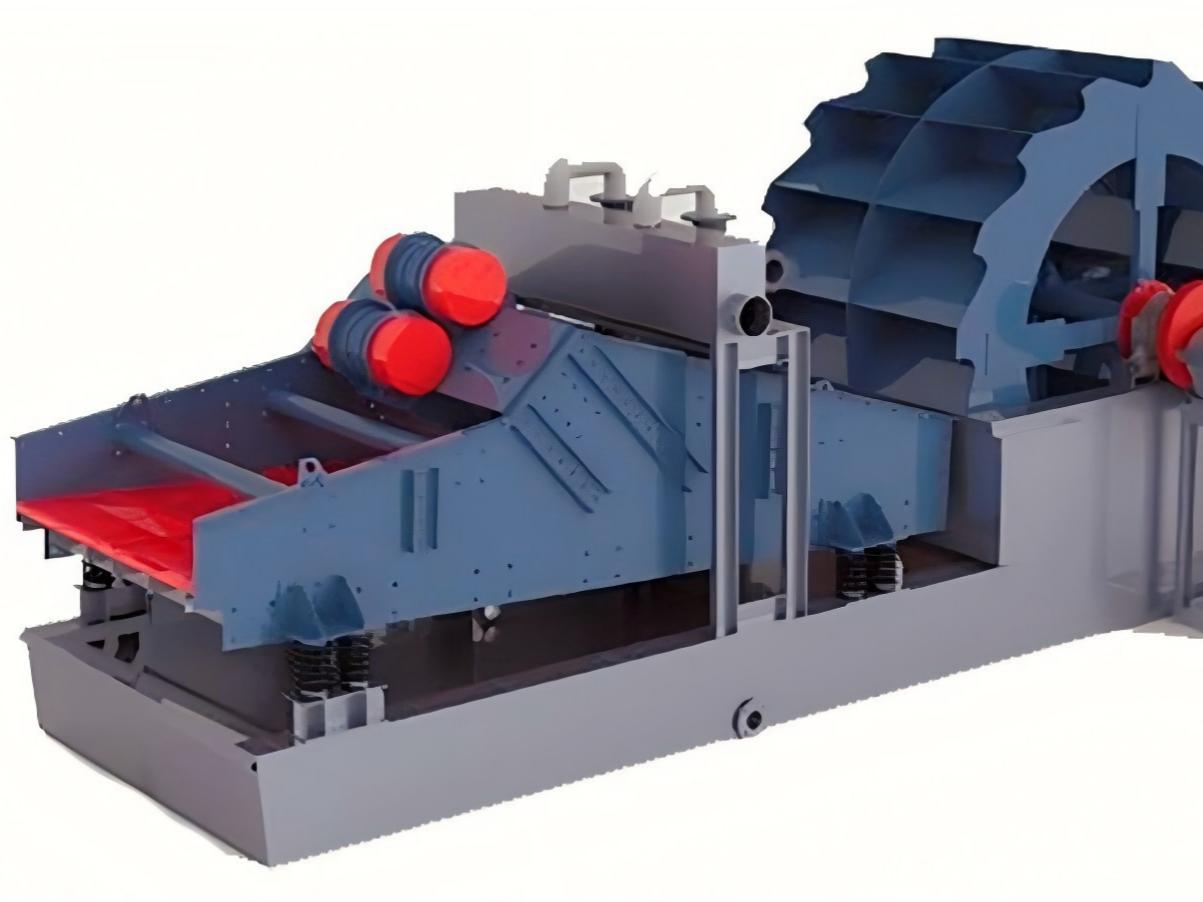

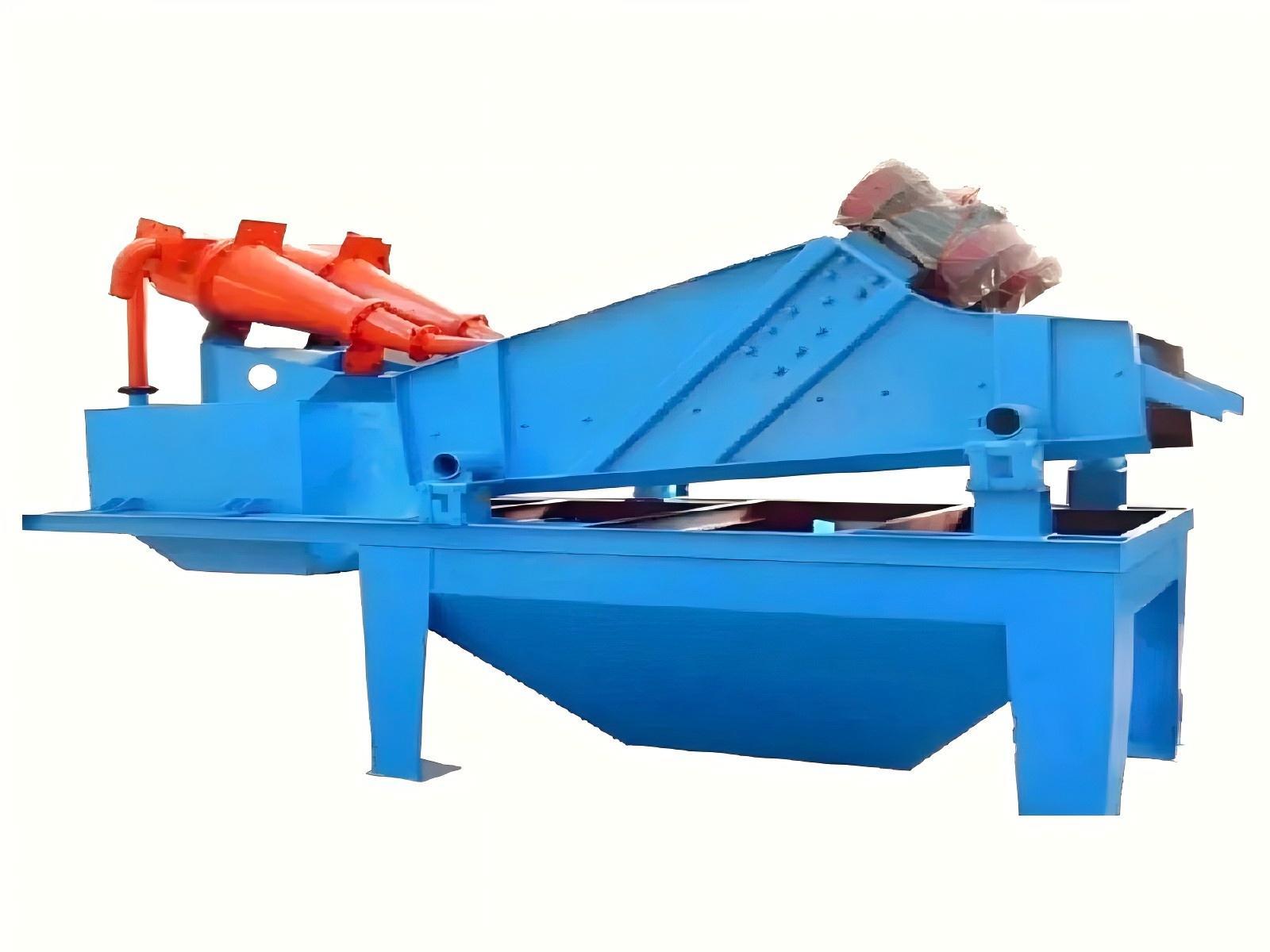

The structural composition of the fine sand recycling machine mainly includes the following parts: motor, slurry pump, hydrocyclone, dewatering screen, cleaning tank and return box.

Motor: provide power to drive the operation of the whole system.

Slurry pump: conveying sand-water mixture to hydrocyclone, realizing sediment separation and fine sand recovery.

Hydrocyclone: concentrates the fine sand through centrifugal grading and provides it to the dewatering screen through the sand settling nozzle.

Dewatering screen: dewatering fine sand, realizing effective separation of fine sand and water.

Washing Tank: Used for buffer storage and mixing and stirring of materials, ready for fine sand recovery.

Return box: return a small amount of fine sand and mud and other impurities back to the cleaning tank for re-processing.

These parts work in coordination with each other to complete the cleaning, dewatering and grading functions of the fine sand recycling machine.

优势Advantages

The vibrating screen adopts polyurethane screen, which has a longer life than other types of screens and is not easy to block holes;

The cyclone is lined with polyurethane, which increases the service life of the entire device and can smoothly complete the work of slurry concentration and liquid clarification;

The fine sand recovery system can recover fine particles in the total discharge volume, which has unparalleled technical and economic advantages over other equipment;

Fine particles are fully recovered, reducing the labor and cleaning cost of the sedimentation tank;

The fine yarn recovery system reduces the natural stacking time of fine materials and can be directly transported and supplied to the market;

According to the different requirements of users, corresponding solutions can be designed.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine