- output:80-300t/h

- Feed size:≤60

- Motor power:22-74kw

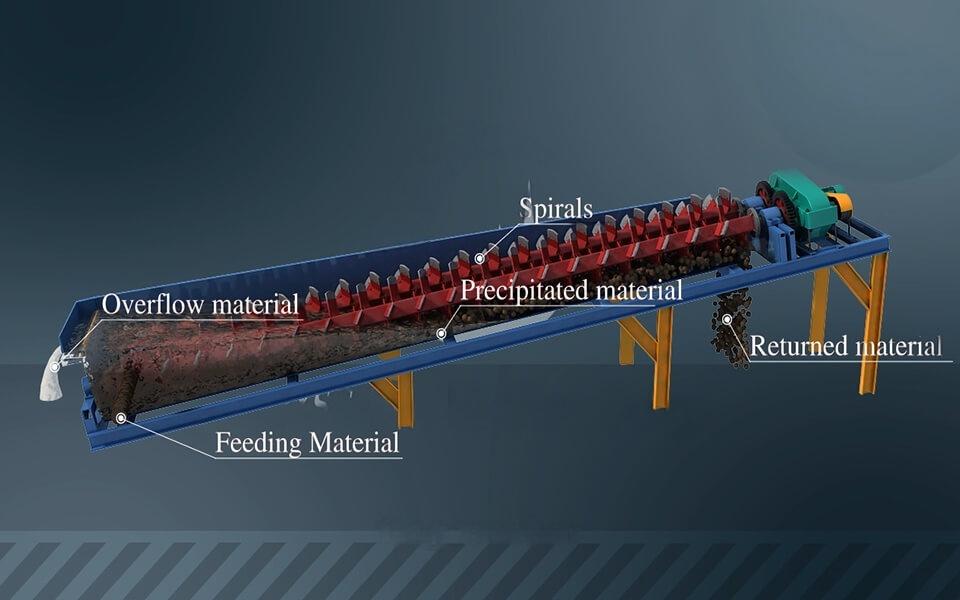

Trough type ore washer is widely used to clean various ores.The ores with above 20%mud will clog the crusher and chute,and this machine can separate the ore and mud by spiral stirring and washing.The cleaned ore willbe discharged from the discharging part,while mud water flows out from the tailing end.

| 类型Type | 规格型号 Model | 转子直径 Diameter(mm) | 入选颗粒(mm) Selected size | 耗水量(t/h) Water consumption | 生产能力 Capacity(t/h) | 电机功率 Power (kw) | 外形尺寸 长*宽*高 ovewHmension | 重量 Weight(kg) |

| 重型单螺旋 Heavy type single spiral |

XKZ-762 | 762 | ≤60 | 355-450 | 80-125 | 22 | 6800×1120×1230 | 9800 |

| XKZ-914 | 914 | ≤60 | 400-600 | 125-175 | 30 | 6980×1200×1340 | 11800 | |

| XKZ-1118 | 1118 | ≤75 | 500-750 | 180-250 | 37 | 7400×1380×1950 | 13900 | |

| 重型双螺旋 Heavy type double spiral |

2XKZ-762 | 762 | ≤60 | 600-800 | 100-150 | 2×22 | 6980×2091×1340 | 16800 |

| 2XKZ-914 | 914 | ≤60 | 700-900 | 150-200 | 2×30 | 7120×2146×1590 | 20800 | |

| 2XKZ-1118 | 1118 | ≤75 | 900-1100 | 200-300 | 2×37 | 8500×2861×2150 | 23870 |

The motor drives the reducer, and the large and small gears drive the cleaning cylinder to rotate at low speed. The aggregate containing mud lumps and stone powder is fed into the feeding port and enters the rotating mixing blade. The cleaned mixing blade is equipped with a rubber lining plate at a certain angle, which continuously lifts and throws it off.

During the scrubbing process, the material moves from the feeding end to the discharging end in multiple cycles and is washed by forward or reverse flushing water. The cleaned aggregate is sieved and dehydrated at the discharging end before being discharged. Wastewater containing sludge flows out through perforated baffles at the discharge or feed end.

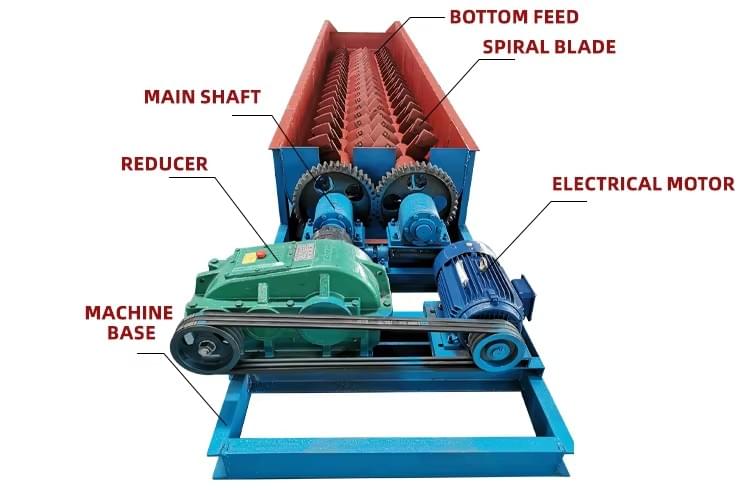

The spiral washing machine is mainly composed of transmission device, spiral, tank body, lower support, overflow trough, etc. It Includes:

1. Transmission Device: It is the power of the spiral work. The spiral rotation is driven by the motor through the V-belt, reducer and gear.

2. Spiral: The main working part of the machine, which plays the role of stirring the minerals. The main shaft is a square shaft welded by channel steel. The upper end is installed on the frame of the transmission device, and the lower end is installed on the lower support. The spiral blade is welded by spring steel plate.

3. Tank Body: It is the body of the machine, which is welded by various section steels and steel plates.

4. Lower Support: Its role is to support the screw shaft.

5. Overflow Trough: Discharge muddy water and debris.