- output:10t/h

- Feed size:

- Motor power:5.5KW

The screw sand washer machine for sale is divided into a single spiral sand washer and a double spiral sand washer. It is mainly used for washing, grading, impurity removal in roads, hydropower, construction, and other industries, as well as fine-grained and coarse-grained materials washing and other operations.

| 规格型号Model | 螺旋直径Diameter(mm) | 产量Capacity(t/h) | 电机功率Power(kw) | 重量Weight(kg) |

| LSX-508 | 508 | 10 | 5.5 | 2200 |

| LSX-610 | 610 | 20 | 7.5 | 3250 |

| LSX-750 | 750 | 50 | 7.5 | 3820 |

| LSX-915 | 915 | 60 | 11 | 4550 |

| LSX-1200 | 1200 | 95 | 15 | 6900 |

| LSX-1500 | 1500 | 130 | 18.5 | 8800 |

The spiral sand washing machine is driven by a motor, and the impeller rotates slowly through the transmission of components such as a V-belt and a reducer. The material (such as sand, stone, ore, etc.) enters the washing tank from the feed tank and is rolled and stirred under the drive of the impeller to remove impurities covering the surface of the material.

• The material is rolled and stirred in the washing tank under the drive of the impeller.

• During this process, collisions and frictions will occur between the materials and between the materials and the impeller and the casing, which will help remove impurities such as soil and stone powder on the surface of the materials.

• Impurities and foreign matter with a smaller specific gravity will be carried away with the water flow and discharged from the drain of the washing tank.

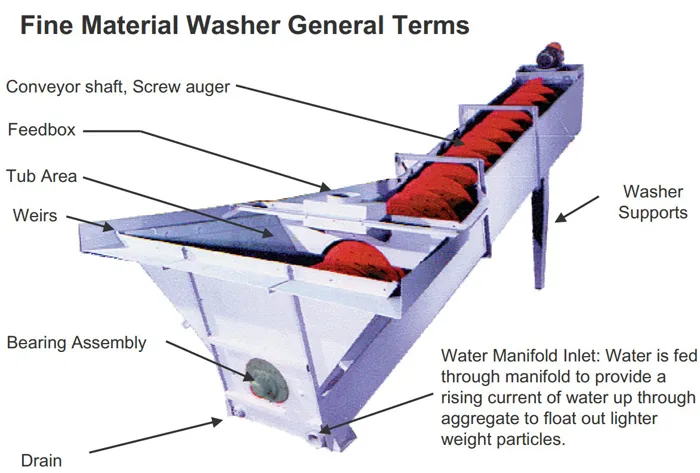

Rotating Spiral Shaft(s): The rotating shaft is the central component of the Coarse Material Washer. It is equipped with paddles in the feed end to provide the scrubbing action, while screw spirals along the remainder of the shaft convey the clean aggregate toward the discharge. The number of paddles on the shaft can be increased to improve scrubbing; however, throughput will be decreased with the addition of extra paddles.

Washer Tub: The tub provides the housing for the aggregates being processed by the Coarse Material Washer. It contains the rotating shaft and is where the aggregates are scrubbed and cleaned.

Rising Current Classifier: The Rising Current Classifier within the tub of the Coarse Material Washer helps to optimize the performance of your machine. An upward rising current addition of water assists in the overflow of unwanted lightweight materials such as twigs, sticks, coals, etc. with the wastewater.

优势Advantages

Spiral sand washer is especially suitable for the washing, grading and impurity removal of medium, fine-grained and coarse-grained materials.

It can effectively clean the sand and gravel with serious mud impurities with a strong cleaning ability

It often used in large scale sand production lines due to great washing ability.