- output:10-150 t/h

- Feed size:/

- Motor power:2.2-11 kw

The disc fiter is a device that uses vacuum as the filtering power to separate the mineral slurry from solid and liquid.This machine fully draws on the advantages of similar foreign products,and optimizes the overall performance and reliability of each component.Achieve user-deficient indicators of metal mineral dehydration.Widely used in dewatering operations in iron concentrates,non-ferrous metal concentrates,coal

| Model | ZPG-15 | ZPG-20 | ZPG-30 | ZPG-40 | ZPG-60 | ZPG-72 | ZPG-96 | ZPG-120 | |

| Filtering area(m²) | 15 | 20 | 30 | 40 | 60 | 72 | 96 | 120 | |

| Filtering plate | Diameter(mm) | 2100 | 3100 | ||||||

| Quantity(pcs) | 6 | 6 | 6 | 8 | 6 | 6 | 8 | 10 | |

| Spindle motor power(kw) | 2.2 | 3 | 3 | 4 | 5.5 | 5.5 | 7.5 | 11 | |

| Stiring motor power(kw) | 3 | 3 | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | |

| Discharging way of fiter cake | Discharge cake | ||||||||

| Weight (t) | 9 | 11 | 12.5 | 14 | 19.3 | 20.3 | 23 | 25.5 | |

| Capacity (t/h) | 10-15 | 15-20 | 22-30 | 30-40 | 45-70 | 50-90 | 60-120 | 80-150 | |

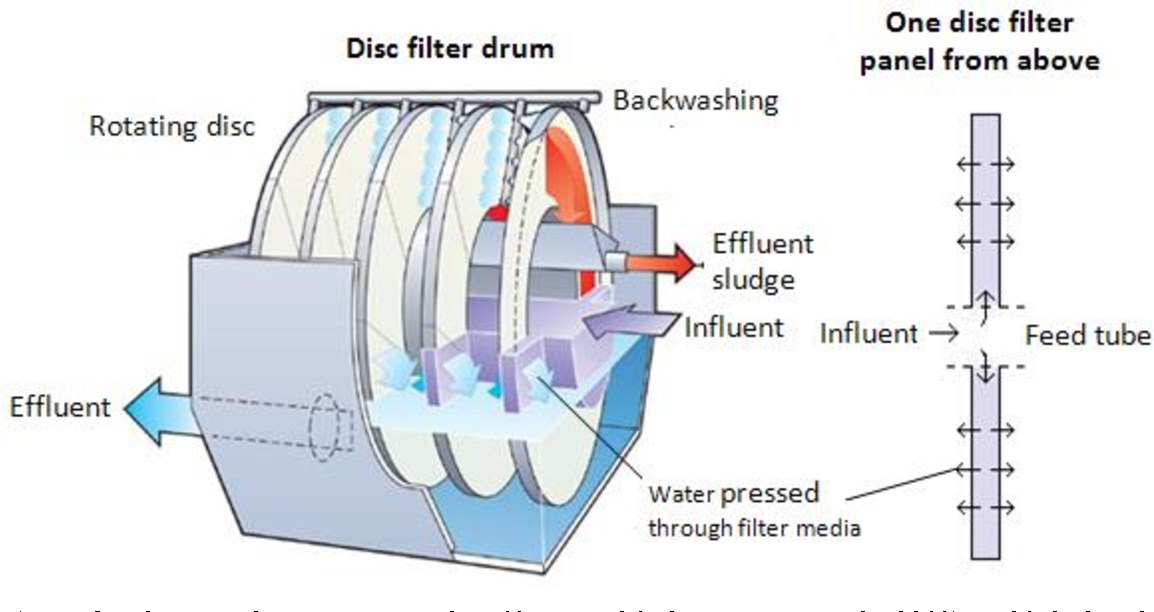

A disc vacuum filter is a solid-liquid separation equipment. The filter disc is driven by a speed-regulating motor through a reducer and an open-gear transmission so that it rotates at a certain speed in a tank filled with slurry. When a filter fan of the filter disc is in the filter adsorption area, a pressure difference is formed on both sides of the filter medium with the help of the vacuum pump, so that the solid material is adsorbed on the filter medium (filter cloth) and forms a filter cake, and the filtrate is discharged through the filtrate pipe and the distribution head. When this filter fan is separated from the slurry level and enters the dehydration area, the filter cake is continuously separated from the water under the suction force of the vacuum, and further discharged from the filtrate pipe and the distribution head, so the filter cake is dried. After entering the unloading area, the filter cake is unloaded from the filter disc with back blowing and scraper, falls into the discharge trough, and is transported away by the ore collection belt conveyor. The whole operation process is carried out continuously.

The disc vacuum filter composes a tank body, a main shaft, a filter disc, a distribution valve, a stripping device, a flushing device, a screen washing device, a transmission device, a discharging device, and other parts.

High-efficiency filtration

The disc vacuum filter can quickly and accurately remove impurities from the liquid and improve the quality and purity of the product. The filter fan is made of high-strength engineering plastics, with a smooth surface, uniform distribution of dehydration holes, and reasonable porosity.

Long service life

The filtrate tube can be made of high-strength wear-resistant ceramic composite steel pipe, which can increase the service life by more than 2 to 3 times. The gas distribution plate and friction plate are made of wear-resistant cast iron and equipped with a dry oil pump for automatic lubrication, with a good sealing effect and long service life.

Easy to maintain

The disc vacuum filter has a simple structure, convenient operation, a small daily maintenance workload, and saves labor costs. It adopts a new type of rake stirring, and the drive system is above the tank body. No sealing measures are required, and there is no slurry leakage.

Energy saving and environmental protection

Compared with traditional filtering equipment, the disc vacuum filter has lower energy consumption and higher environmental protection performance.

High safety

The disc vacuum filter is equipped with a safety protection device, which can automatically shut down under abnormal conditions to ensure the personal safety of the operator.

Disc Vacuum Filter

High-efficiency filtration

Structural Optimization and Durability

Automation and Intelligence

Easy Maintenance

Environmentally friendly materials

The disc vacuum filter is made of environmentally friendly materials, which are harmless to the environment and conform to the green development concept of today’s society.