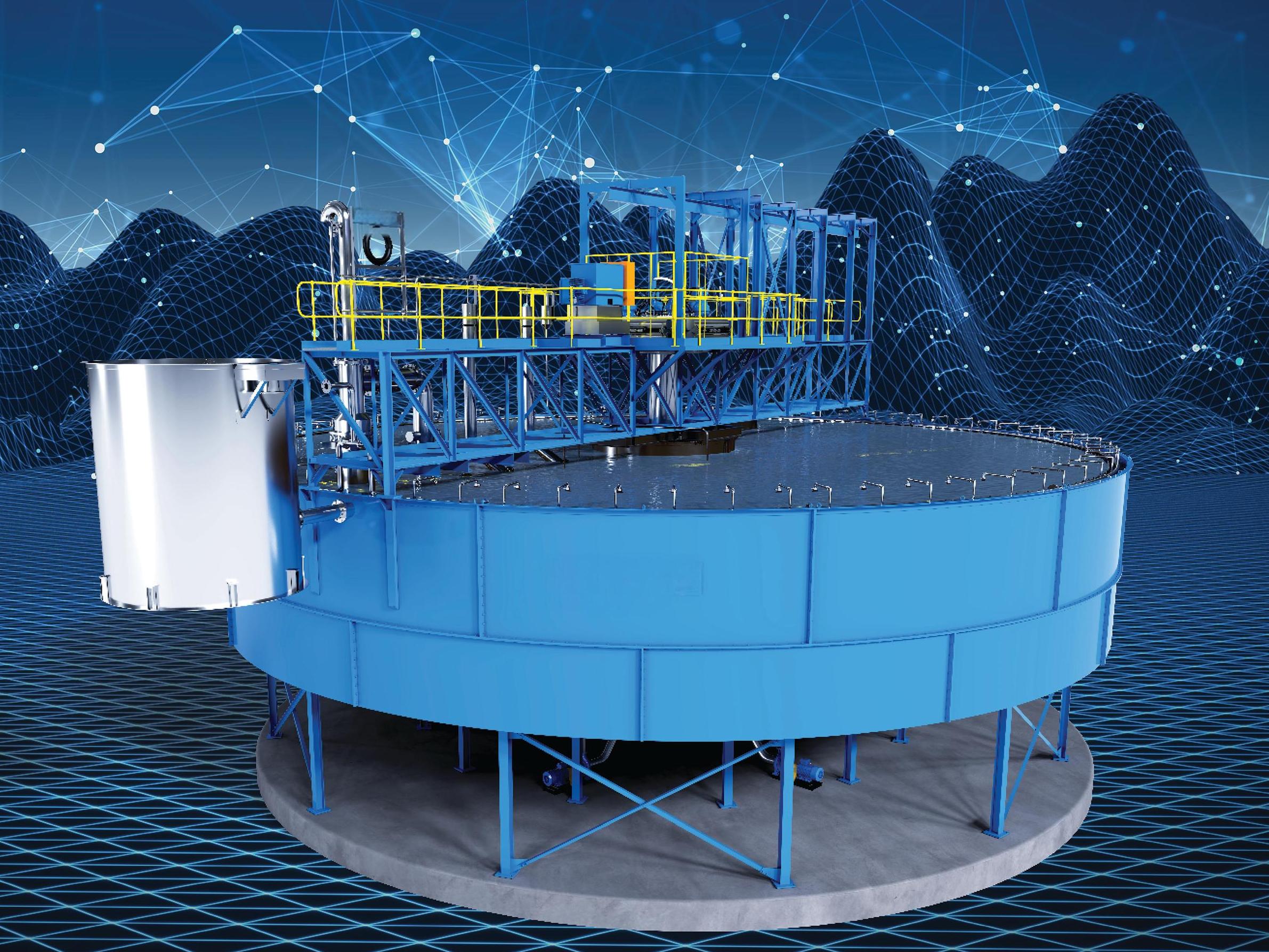

The thickener is to improve the pulp concentration,make the production process to obtain suitable concentration.Generally divided into two kinds,peripheral transmission and center transmission,commonly used in the ore dressing plant concentrate,middling and tailings.It is widely used in metallurgy,chemical and other industries such as coal,environmental protection.

Thickener Main technical parameters:

| Model | Transmission form | Diameter (m) |

Depth (m) |

Capacity (t/d) |

Power (kw) |

Weight (kg) |

| NZS-1 | Centre drive | 1.8 | 1.8 | 5.6 | 1.1 | 1300 |

| NZS-3 | Centre drive | 3.6 | 1.8 | 22.4 | 1.1 | 2975 |

| NZS-6 | Centre drive | 6 | 3 | 62 | 3 | 8700 |

| NZS-9 | Centre drive | 9 | 3 | 140 | 3 | 16682 |

| NZS-12 | Centre drive | 12 | 3.5 | 250 | 3 | 33131 |

| NG-15 | Rollers | 15 | 3.5 | 390 | 5.5 | 9120 |

| NG-18 | Rollers | 18 | 3.5 | 560 | 5.5 | 10000 |

| NG-24 | Rollers | 24 | 3.7 | 1000 | 7.5 | 24000 |

| NG-30 | Rollers | 30 | 3.6 | 1570 | 7.5 | 26420 |

| NT-15 | Rack gear | 15 | 3.5 | 390 | 5.5 | 11000 |

| NT-18 | Rack gear | 18 | 3.5 | 560 | 5.5 | 12120 |

| NT-24 | Rack gear | 24 | 3.7 | 1000 | 7.5 | 28270 |

| NT-30 | Rack gear | 30 | 3.6 | 1570 | 7.5 | 30888 |

| NT-45 | Rack gear | 45 | 5.1 | 2400 | 11 | 58640 |

| NT-50 | Rack gear | 50 | 4.5 | 3000 | 11 | 65920 |

| NT-53 | Rack gear | 53 | 5.1 | 3400 | 11 | 69410 |

The industrial thickener consists of a cylindrical basin filled with water, the contents of which are completely purified with the help of sedimentation or solid separation from the liquid. The working method of the thickener is that after entering the industrial wastewater into the tank and reducing its turbulence, part of the solid water particles are exposed to various forces such as gravity and centrifugal force due to the difference in weight and the movement of the thickener paddles and settle at the bottom of the pond. After the formation of the thick paste (Underflow) in the lower part of the thickener tank, it is time to leave the clear liquid formed on the water, which is called the thickener head or Overflow, which takes place through the channel in the upper part of the pond. In the last stage of the thickener method, the sediments deposited in the end section are sent to the central duct of the thickener with the help of one or more rotating arms and are thus removed.

The high-efficiency thickener mainly consists of key components including the feed pipe, feed launder, scraper, rake arm, overflow pipe, and underflow discharge pipe. Generally, a thickener is primarily divided into three layers. The first layer is the feed layer, which is responsible for processing and delivering the ore slurry into the settling tank. The second layer is the settling layer, where impurities in the slurry gradually settle, forming purified slurry. The third layer is the bottom sludge discharge layer, mainly used for removing the settled impurities.

1. Large processing capacity per unit area and high concentration efficiency.

2. Hydraulic multi-point drive, stepless speed regulation, high mechanical strength, and overload protection function.

3. It adopts hydraulic rake device and operates reliably.

- Pulse jet bag dust collector

- Linear vibrating screen

- Powder separator

- Screw conveyor

- Bucket elevator

- Mobile screening plant

- Mobile sand making plant

- Mobile cone crushing plant

- Mobile impact crushing plant

- Mobile jaw crushing plant

- Spiral chute

- Bucket wheel sand washer

- Jigging machine

- Screw sand washer

- SF series flotation machine