- output:16-60

- Feed size:150×250

- Motor power:5.5KW

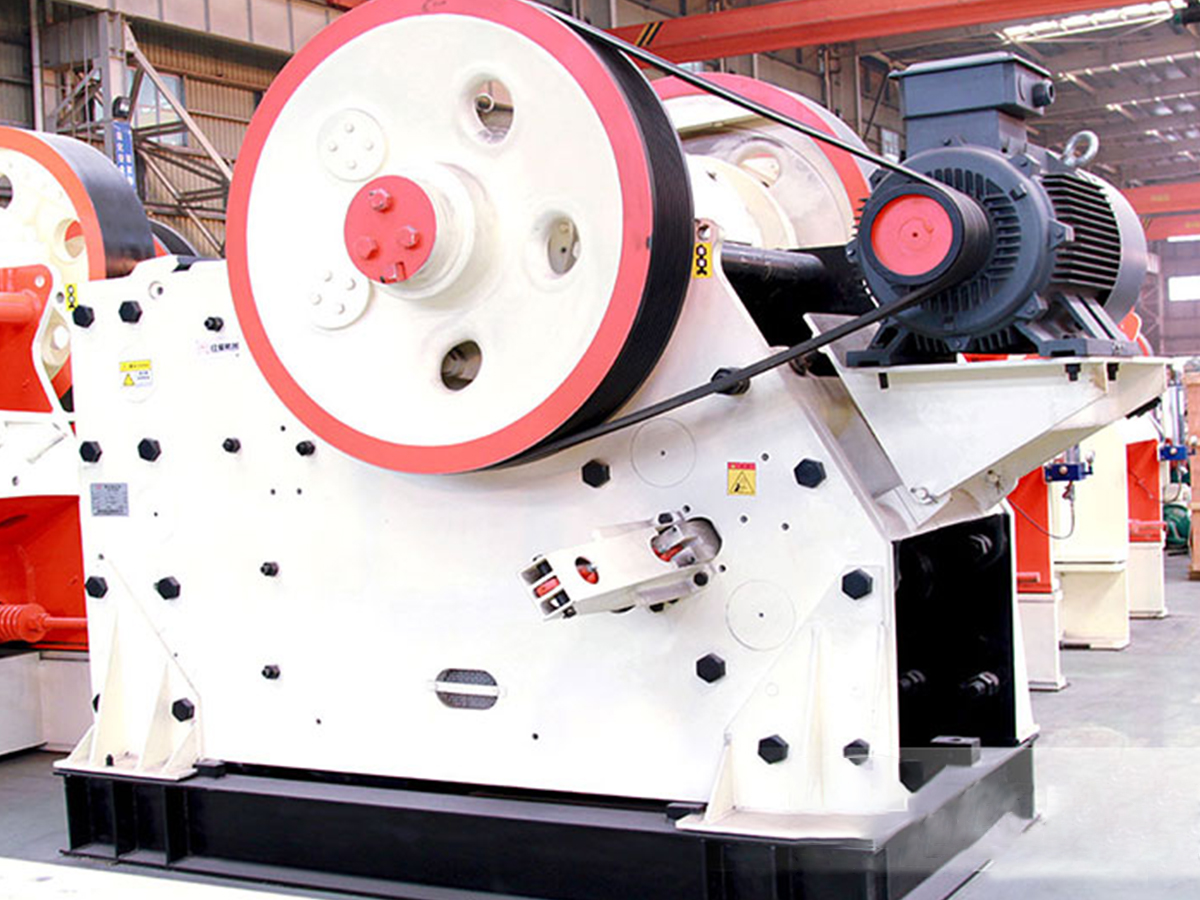

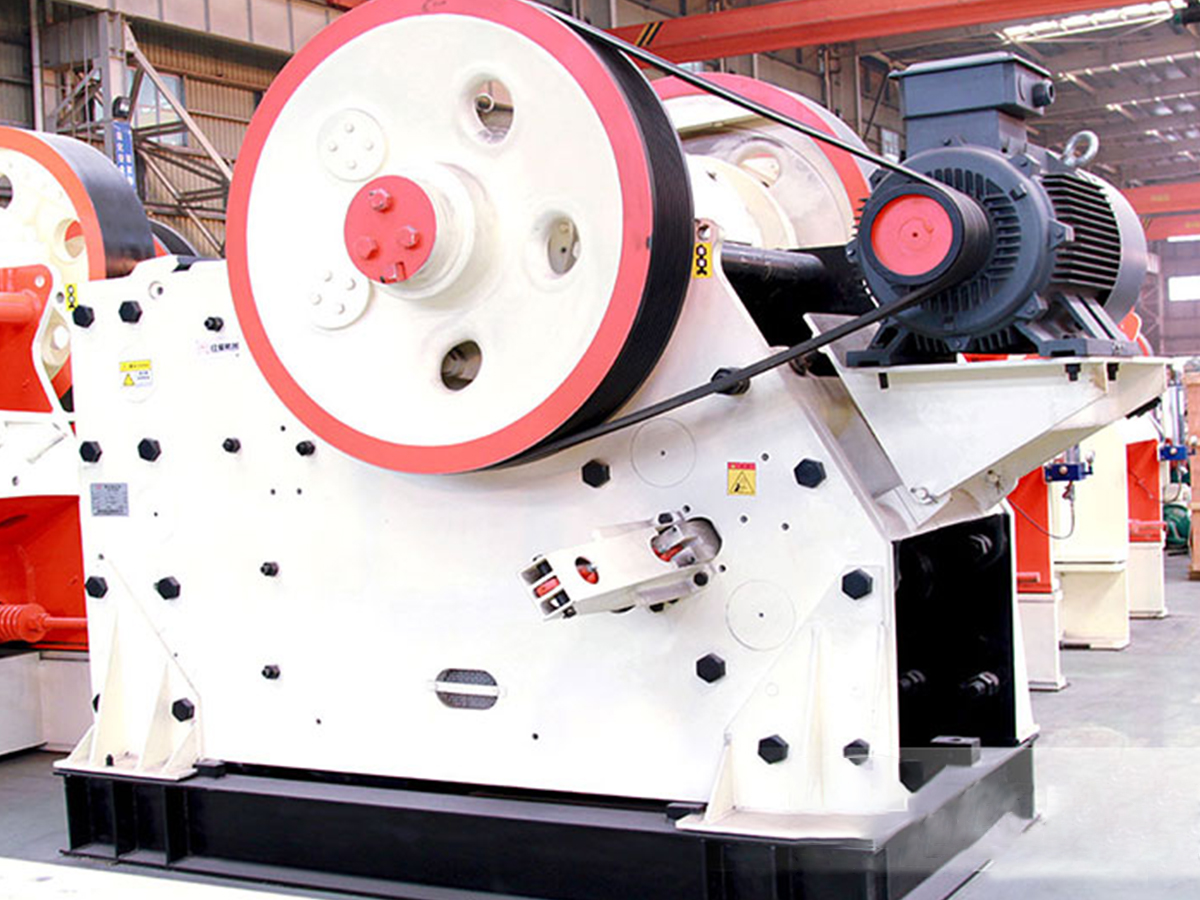

Jaw crusher has characteristics of high crushing ratio,simple structure,reliable operation,easy maintenance,economical operating cost,etc.Jaw Crusher is widely used in mining,smelting,building material, highway,railway,water conservancy,chemical industry and many otherindustries with compression strength no texceeding 350 Mpa.

| 型号Model | 进料口尺寸 Feeding inlet size(mm |

最大进料粒度 Max.Feed size (mm) |

排 料 口 调 整 范 围 Adjustment range of discharging outlet (mm) |

处理能力 Capacity (t/h) |

偏心轴转速 Rotation speed (r/min) |

电动机功率 Power(kw) | 总重量 Weight(t) | 外形尺寸(长×宽×高) Overall dimension (L×W×H)(mm) |

| PE 150×250 | 150×250 | 125 | 10-40 | 13 | 260 | 5.5 | 1.1 | 1000×870×990 |

| PE 250×400 | 250×400 | 210 | 20-60 | 5-20 | 300 | 15 | 3.2 | 1300×1090×1270 |

| PE 400×600 | 400×600 | 340 | 40-100 | 16-60 | 275 | 30 | 7 | 1730×1730×1630 |

| PE 400×900 | 400×900 | 340 | 40-100 | 40-110 | 275 | 55 | 11 | 1905×2030×1658 |

| PE 500×750 | 500×750 | 425 | 50-100 | 40-110 | 275 | 55 | 12 | 1980×2080×1870 |

| PE 600×900 | 600×900 | 500 | 65-160 | 50-180 | 250 | 75 | 17 | 2190×2206×2300 |

| PE 750×1060 | 750×1060 | 630 | 80-140 | 110-320 | 250 | 110 | 31 | 2660×2430×2800 |

| PE 900×1200 | 900×1200 | 750 | 95-165 | 220-450 | 200 | 160 | 52 | 3380×2870×3330 |

| PE 1000×1200 | 1000×1200 | 850 | 195-265 | 315-500 | 200 | 160 | 55 | 3480×2876×3330 |

| PE 1200×1500 | 1200×1500 | 1020 | 150-350 | 400-800 | 180 | 220 | 93 | 4200×3300×3500 |

| PE 1500×1800 | 1500×1800 | 1200 | 220-350 | 500-1000 | 180 | 280 | 122 | 5160×3660×4248 |

| PEX150×750 | 150×750 | 120 | 18-48 | 8-25 | 320 | 15 | 3.8 | 1200×1530×1060 |

| PEX250×750 | 250×750 | 210 | 15-60 | 13-35 | 330 | 30 | 6.5 | 1380×1750×1540 |

| PEX250×1000 | 250×1000 | 210 | 15-60 | 16-52 | 330 | 37 | 7 | 1560×1950×1390 |

| PEX250×1200 | 250×1200 | 210 | 15-60 | 20-61 | 330 | 45 | 9.7 | 2140×2096×1500 |

| PEX300×1300 | 300×1300 | 250 | 20-90 | 16-105 | 300 | 55 | 15.6 | 2720×2210×1600 |

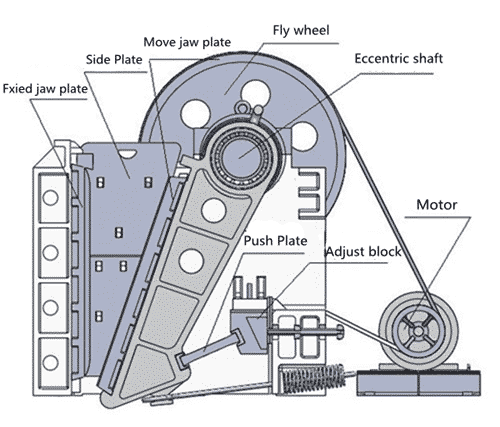

The working mode of jaw crusher is grinding and extrusion. Its working principle is: through the eccentric wheel to move jaw up and down, when the jaw rises to the fixed jaw plate close, and at the same time the material is crushed or split; When the moving jaw goes down, the Angle between the elbow plate and the moving jaw becomes smaller, the moving jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring.

When feeding the jaw crusher, the material is poured into the crushing chamber containing the jaw teeth from the top entrance, and the jaw teeth push the material to the wall of the chamber with great force and break it into smaller stones.

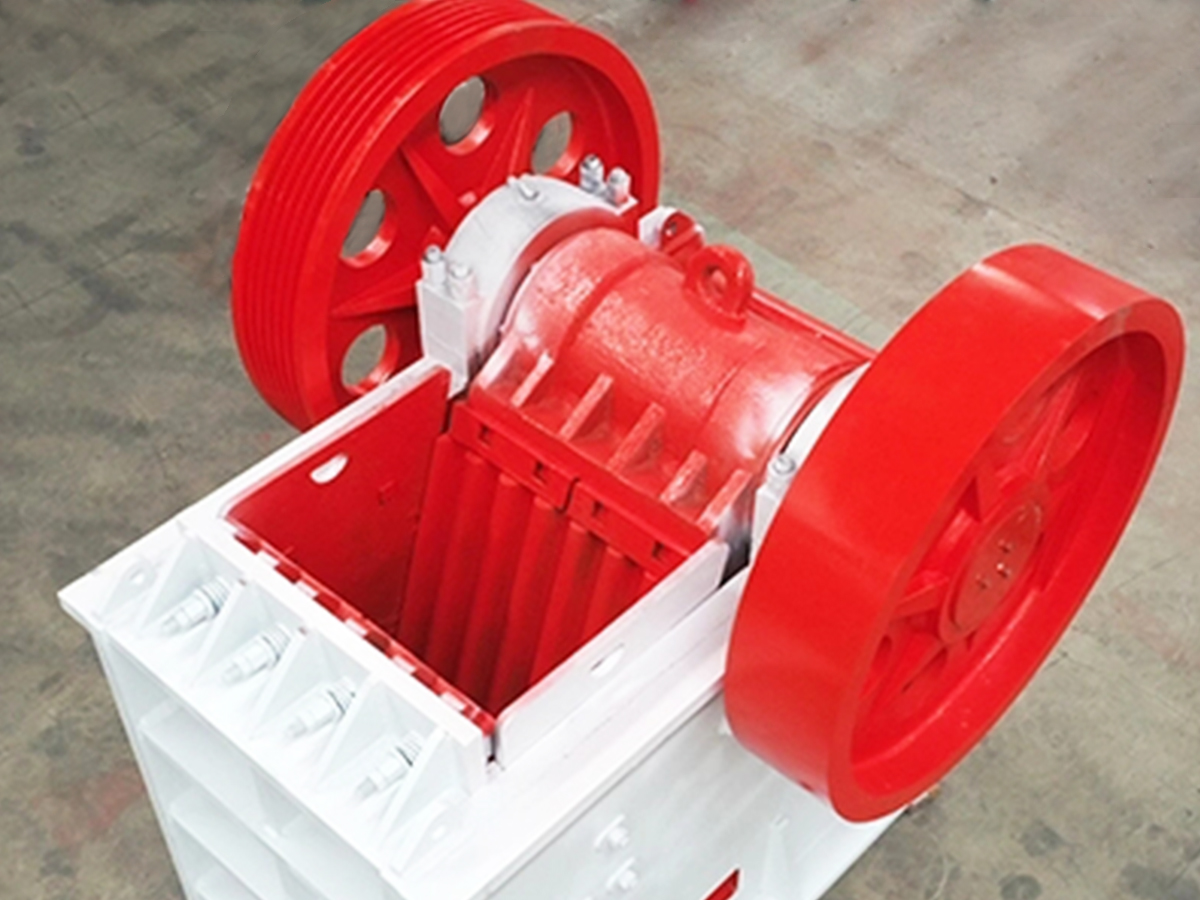

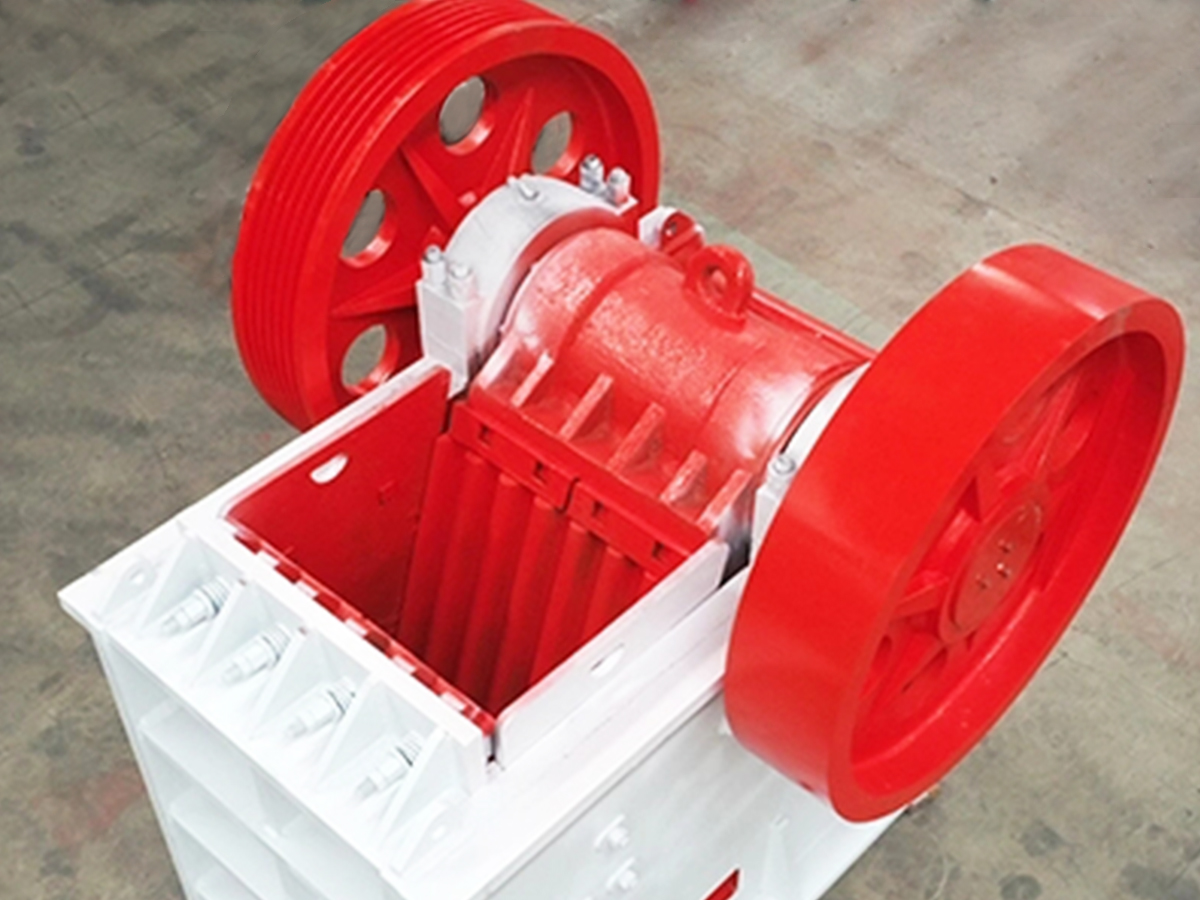

The jaw crusher is composed of bearings, eccentric shaft, moving jaw plate, fixed jaw plate, spring, toggle plate, side liner, etc.

优势Advantages

01.Mid-Mount Base frame

Mid-mount base frame allows machinery to maintain a low profile in portable jaw crusher installations.

02.AGgresive Nip Angle

Designed with an aggressive nip angle, operators get consistent stone processing and strong capacity.

03.Cast Steel Components

High grade cast steel components (including patented fixed jaw frame)and crusher wear parts handle higher loads and last longer.

04.Composite Draft Guard

Lightweight, composite drive guard can be handled by one person, operates quietly, and achieves tightest fit up.