- output:30-50t/h

- Feed size:

- Motor power:37-55KW

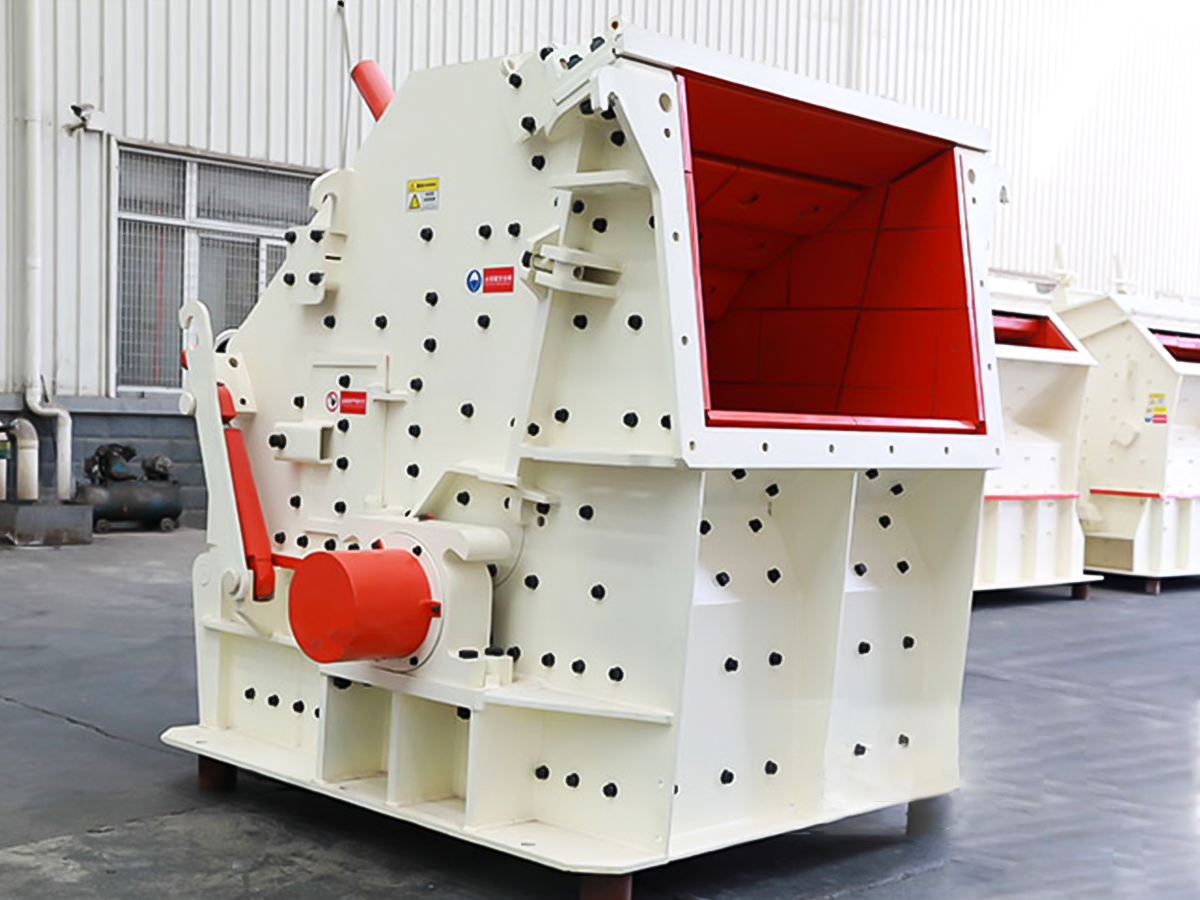

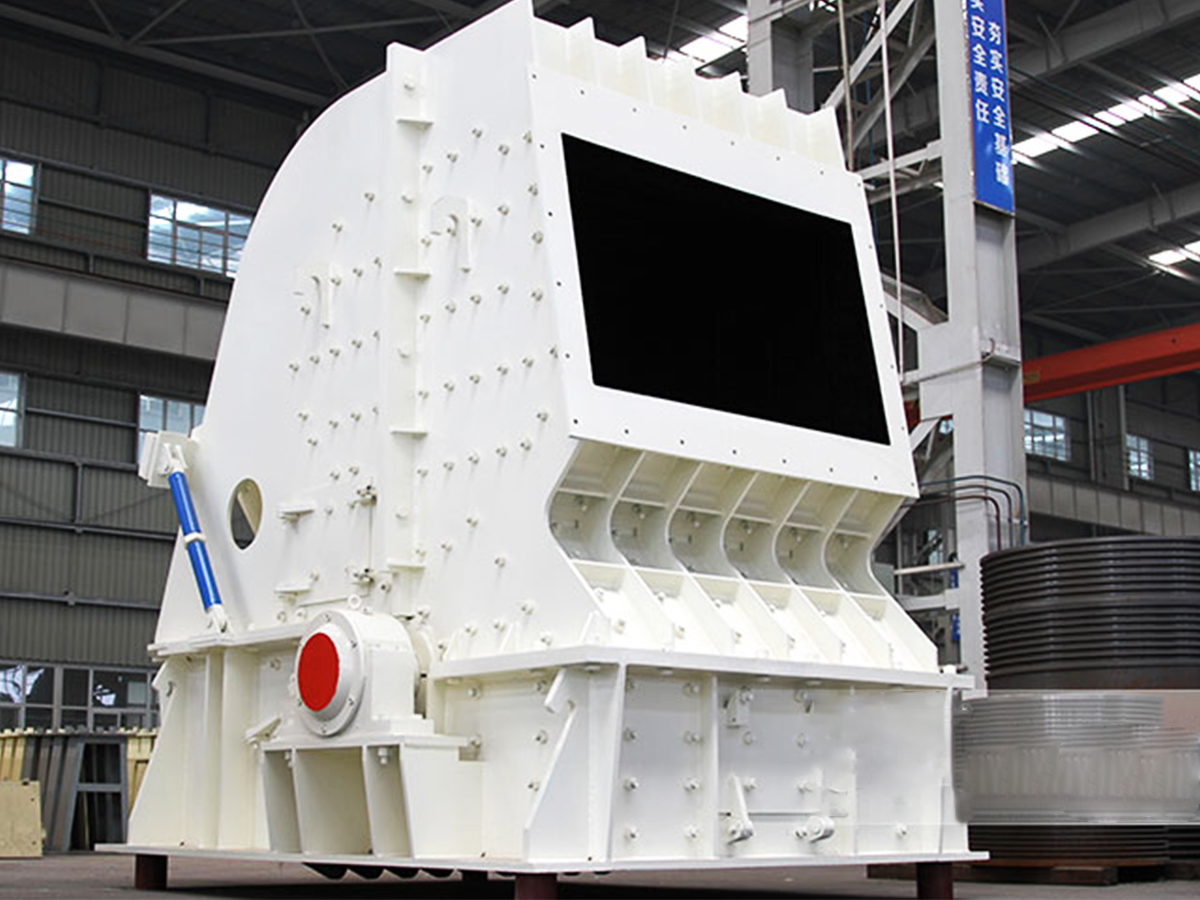

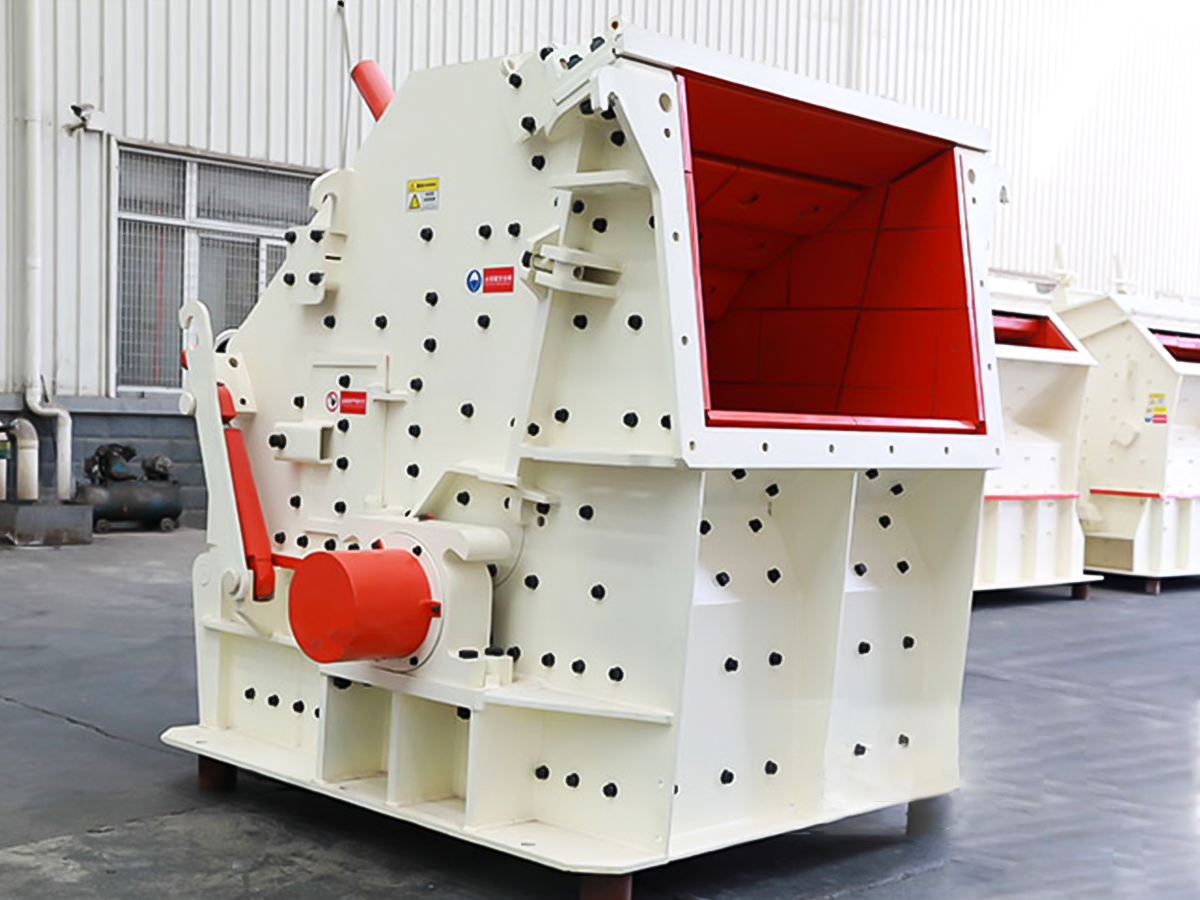

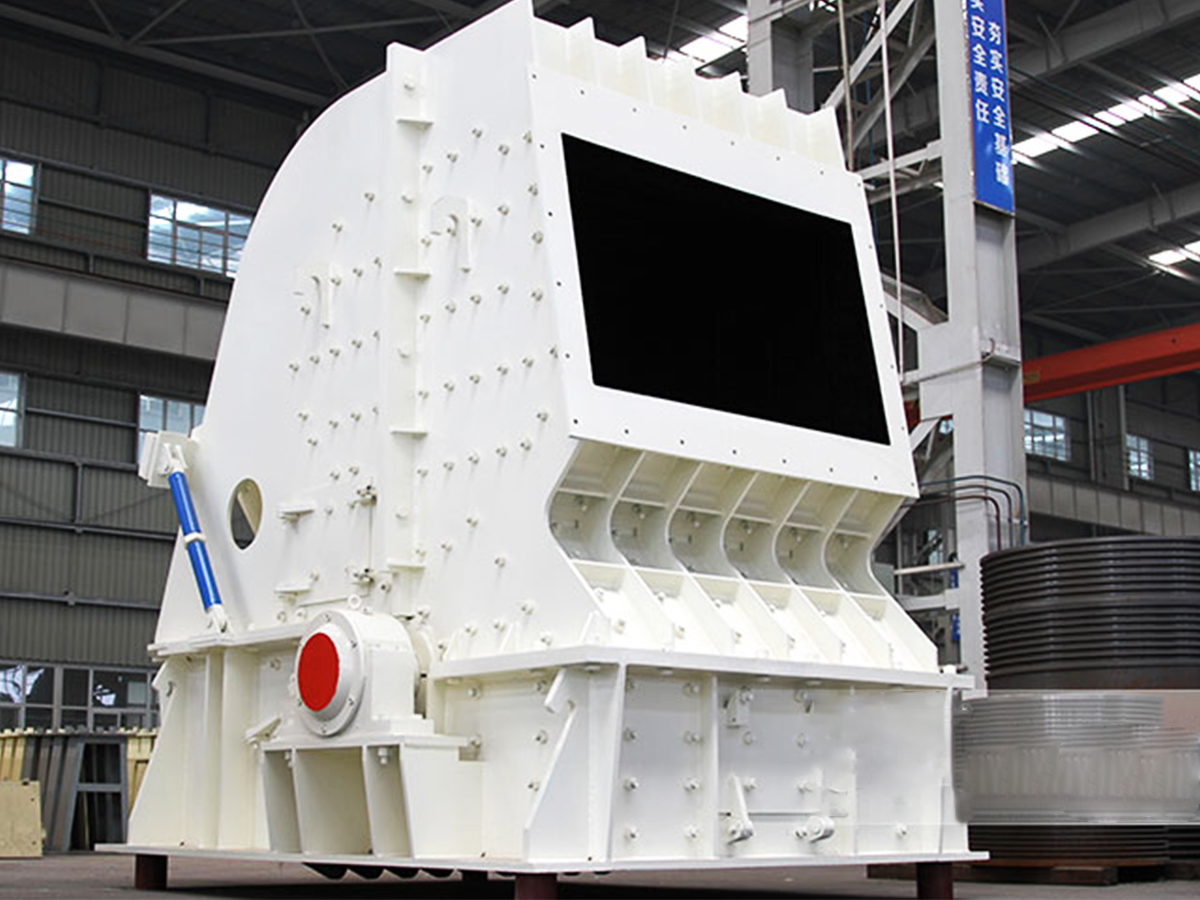

This Impact Crusher is a kind of high-energy and low-impact shock with an international advanced level. Its performance plays an irreplaceable role in various ore fine-breaking equipment, with effective, practical, and reliable performance.In addition, it can be widely used in metal and non-metal ore, cement, refractory materials, abrasives, glass raw materials, building aggregates, artificial sand, river pebbles, rocks, and so on. With a shaping function, the product is cubic, and the bulk density is large. During the production process, the stone material can form a protective bottom layer, and the body is wear-free and durable. Through the ability of non-crushed materials, the impact of the moisture content of the material is small, the moisture content can reach 8%. The product has an excellent grain shape, is cubic, and has a very low needle-like content. It is suitable for aggregate shaping, artificial sand making, and high-grade highway aggregate production.

| 规格型号 Model | 规 格Specification(mm) | 进料口尺寸(mm) Feed opening size | 最大进料边长 Max feeding size(mm) |

生产能力 Capacity(t/h) |

电机功率 Motor power(kw) |

| PF-1008 | 中1000×800 | 400×830 | 300 | 30-50 | 37-55 |

| PF-1010 | φ1000×1050 | 400×1080 | 350 | 50-80 | 55-75 |

| PF-1210 | φ1250×1050 | 400×1080 | 350 | 70-120 | 110-132 |

| PF-1214 | φ1250×1400 | 400×1430 | 400 | 130-180 | 160-200 |

| PF-1315 | 中1320×1500 | 680×1520 | 400/ | 160-250 | 180-260 |

| PF-1320 | φ1320×2000 | 680×2030 | 400 | 300-350 | 300-375 |

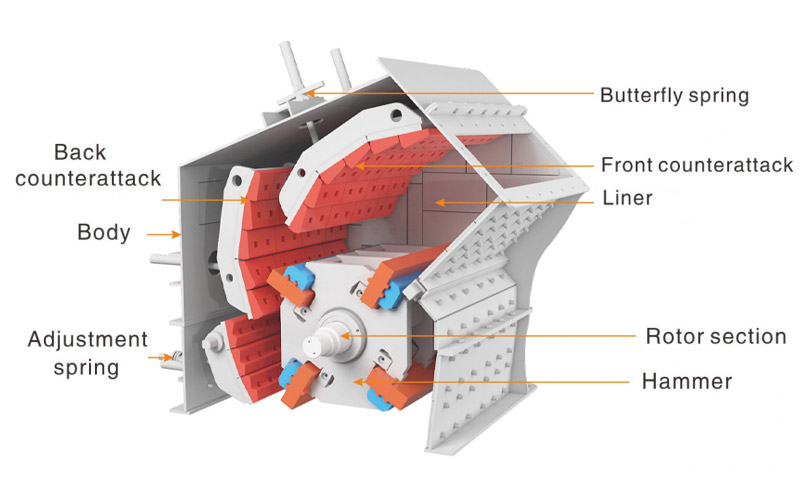

Driven by the electric motor, the rotor inside the impact crusher rotates at high speed. When the material enters the plate hammer crushing zone, it is crushed by impact with the plate hammer and then thrown to the liner plate to be crushed again. Then it bounces back to the plate hammer area from the liner plate and crushes again, and this process is repeated.

The material is repeatedly crushed from large to small in the impact chamber until it is crushed to the required size, and then discharged from the discharge port. The gap between the impact frame and the rotor can be adjusted to change the material size and shape of the material.

An impact crusher comprises a rotor, impact bars, and wear plates. The rotor is the main component of the crusher, and it rotates at high speed to generate the necessary impact force. The impact bars, which are attached to the rotor, are responsible for crushing the material. The wear plates, also attached to the rotor, protect it from wear and tear caused by the impact force.

High reduction ratios up to 30:1

Cubical gravel crusher with high crush count

Selective crushing by speed and breaker plate adjustment

Interchangeable wear parts

Capacities from 5 to 700 TPH

Available with front or rear opening housings

Feed sizes up to 16”

One-man changeout of breaker bars