- output:

- Feed size:

- Motor power:

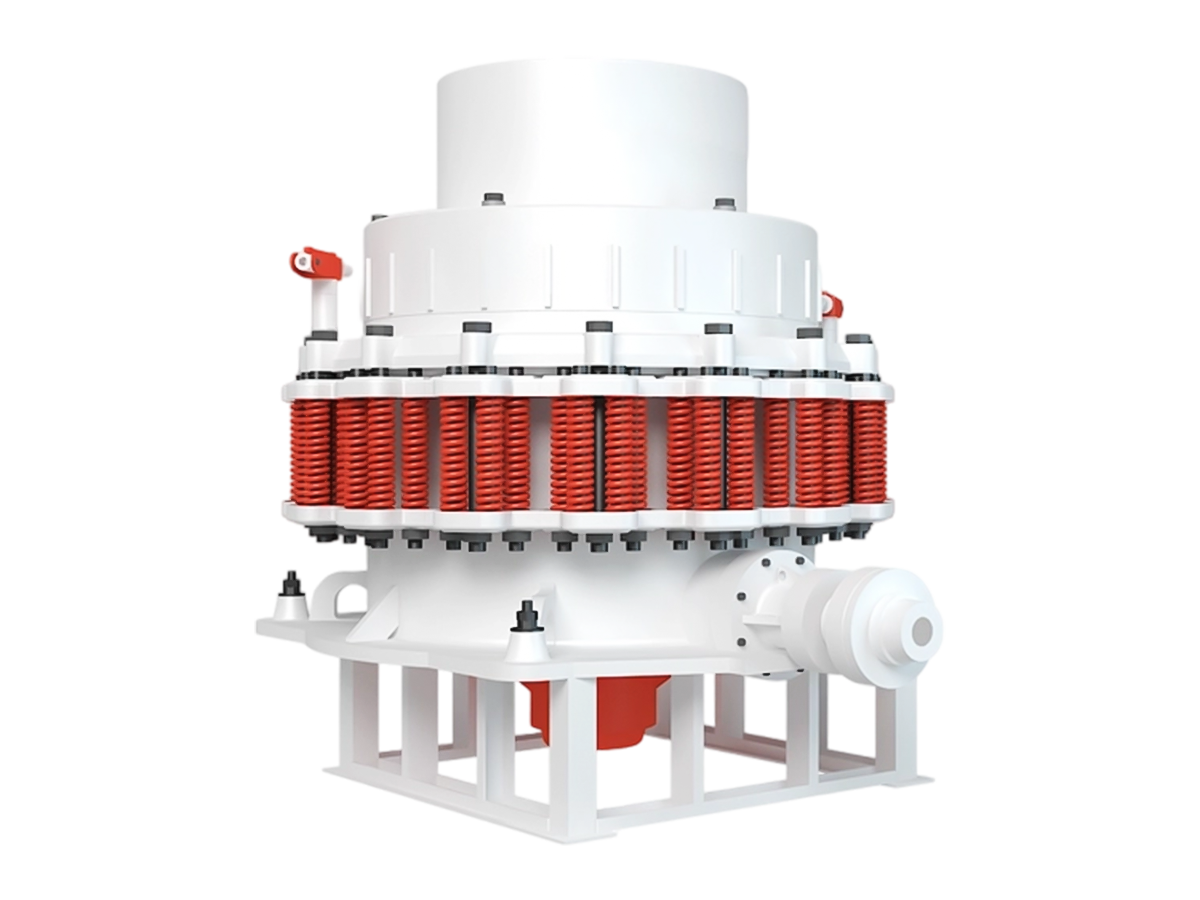

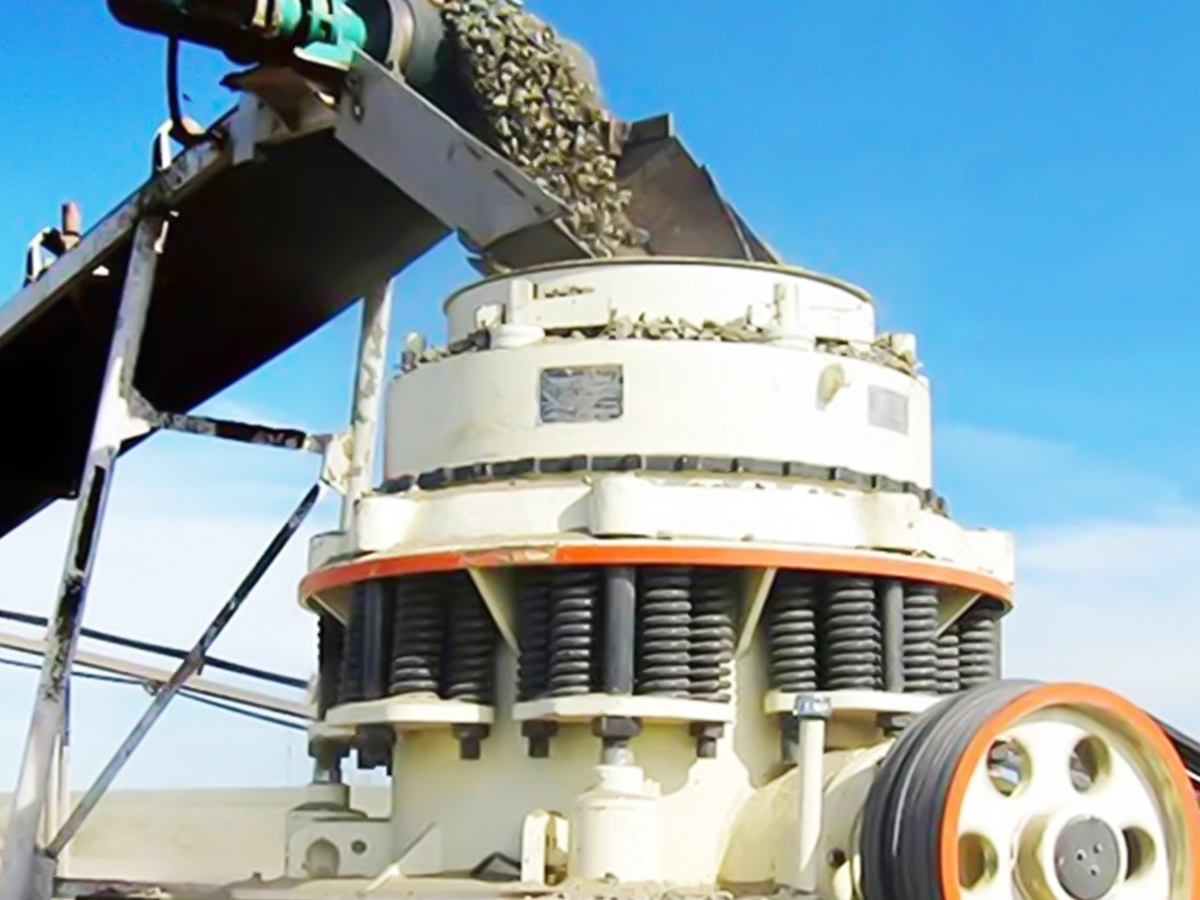

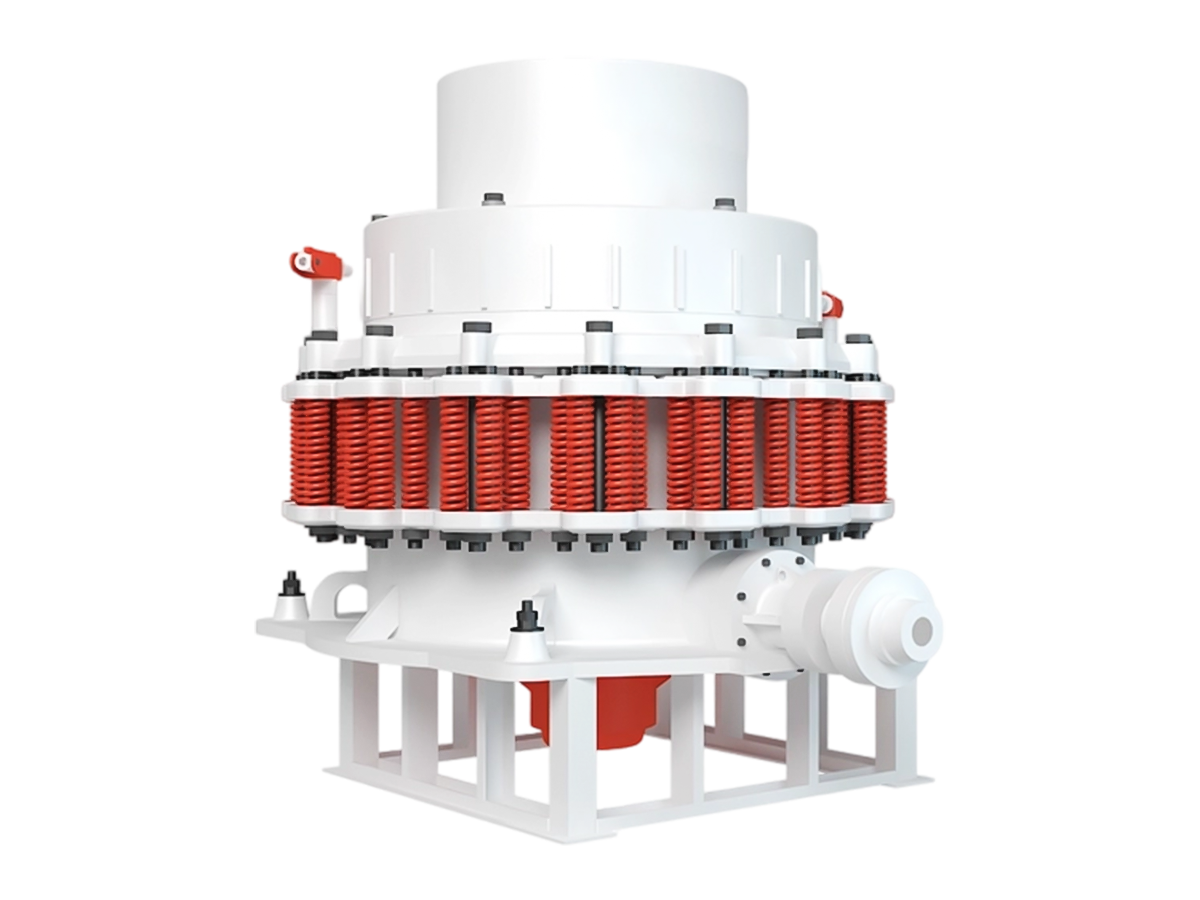

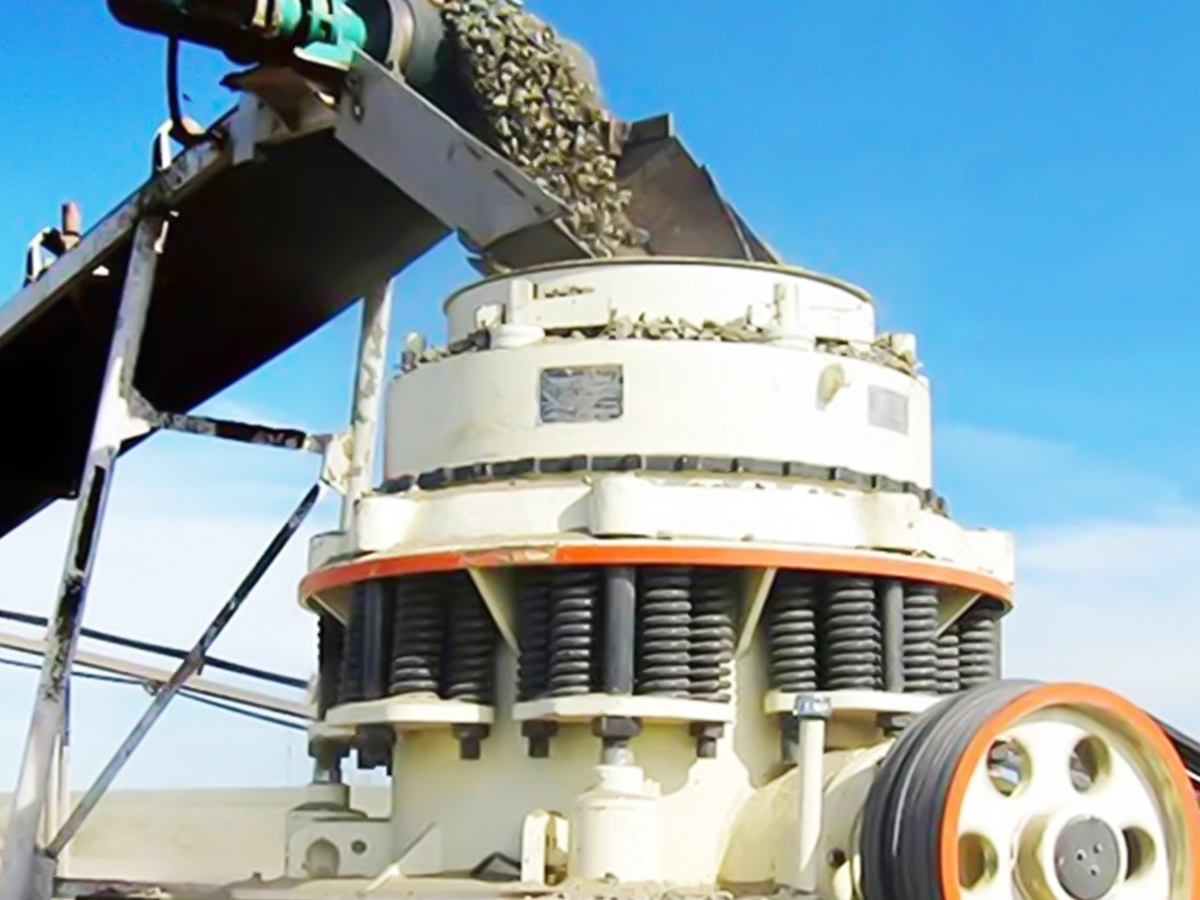

Spring cone crusher is suitable for crushing various of mid-hard and above mid-hard ores and rocks.This crusher has advantages of reliable structure,high productivity,easy adjustment and less cost in operation.The spring release system is also called overload protection system that allows oversized stone to pass through the crushing chamber without damage the crusher.It uses dry oil and water as sealing method,which separates plaster powder and lubricant,guarantee lubrication oil clean.The type of crushing chamber depends upon the feeding size and finished product size. The standard head model is applied to the medium crushing,the medium head model is applied to the medium and fine crushing,and the short head model is applied to the fine crushing.

| 型号 Model | 椎体直径Diameter of cone head(mm) | 进料尺寸 Max.Feedsize(mm) |

调节范围 Adjusting range of output size(mm) |

产量Capacity(t/h) | 功率 Power (kw) |

转速 Speed of eccentric shaft(r/min) |

重量 Weight(t) |

外形尺寸Dimensions(mm) |

| PYB900 | 900 | 115 | 15-50 | 50-70 | 55 | 333 | 11.2 | 2692×1640×2350 |

| PYZ900 | 900 | 60 | 5-20 | 20-65 | 55 | 333 | 11.2 | 2692×1640×2350 |

| PZD900 | 900 | 50 | 3-13 | 15-50 | 55 | 333 | 11.3 | 2692×1640×2350 |

| PYB1200 | 1200 | 145 | 20-50 | 100-150 | 110 | 300 | 24.7 | 2790×1878×2844 |

| PYZ1200 | 1200 | 100 | 8-25 | 42-135 | 110 | 300 | 25 | 2790×1878×2844 |

| PYD1200 | 1200 | 50 | 3-15 | 18-105 | 110 | 300 | 25.3 | 2790×1878×2844 |

| PYB1750 | 1750 | 215 | 25-50 | 150-250 | 160 | 245 | 50.3 | 3910×2894×3809 |

| PYZ1750 | 1750 | 185 | 10-30 | 115-180 | 160 | 245 | 50.3 | 3910×2894×3809 |

| PYD1750 | 1750 | 85 | 5-13 | 75-120 | 160 | 245 | 50.2 | 3910×2894×3809 |

| PYB2200 | 2200 | 300 | 30-60 | 200-350 | 260-280 | 220 | 80 | 4622×3302×4470 |

| PYZ2200 | 2200 | 230 | 10-30 | 150-250 | 260-280 | 220 | 80 | 4622×3302×4470 |

| PYD2200 | 2200 | 100 | 5-15 | 120-200 | 260-280 | 220 | 81.4 | 4622×3302×4470 |

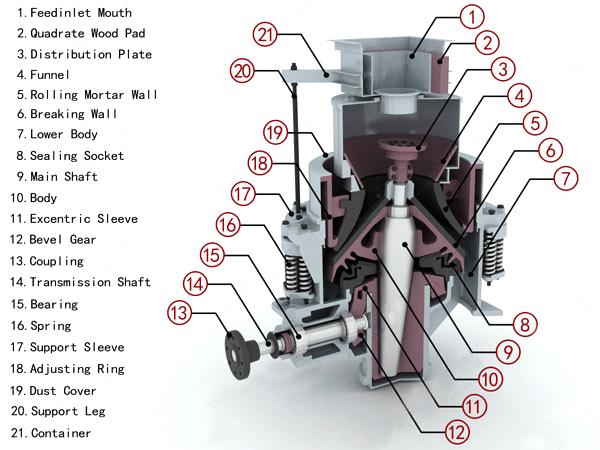

The spring cone crusher operates by drawing material into the crushing chamber between the fixed concave bowl and the movable crushing head, or mantle. As the mantle gyrates around the concave, it reduces the size of the material through compression. The crushed material is then discharged through an opening at the bottom of the crusher. The spring system allows the mantle to be displaced temporarily if non-crushable material enters the chamber, preventing damage to the crusher. The size of the crushed material can be adjusted by changing the distance between the mantle and the concave.

The spring cone crusher is made up of a main frame, transmission shaft, eccentric bushing, bowl-shaped bearing, crushing cone, adjusting device, adjusting sleeve, spring etc.

优势Advantages

1.Strong crushing force; High efficiency; High crushing capacity.

2. Newest improved design with our own technical patent.

3.As spare parts selection and structural design is reasonable, the lifespan will be longer.

4.Different types of crushing chambers to satisfy different customers’ requirement.