- output:190t/h

- Feed size:

- Motor power:90kw

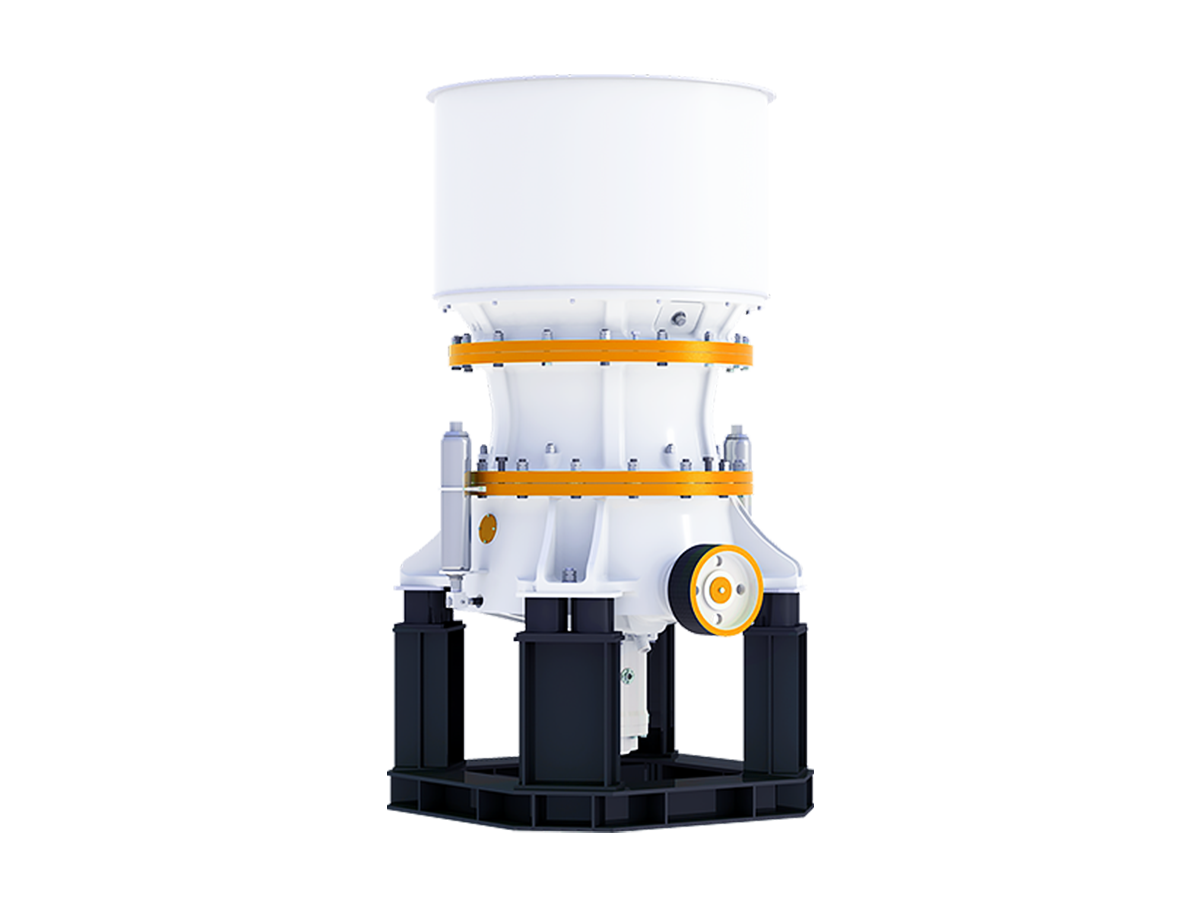

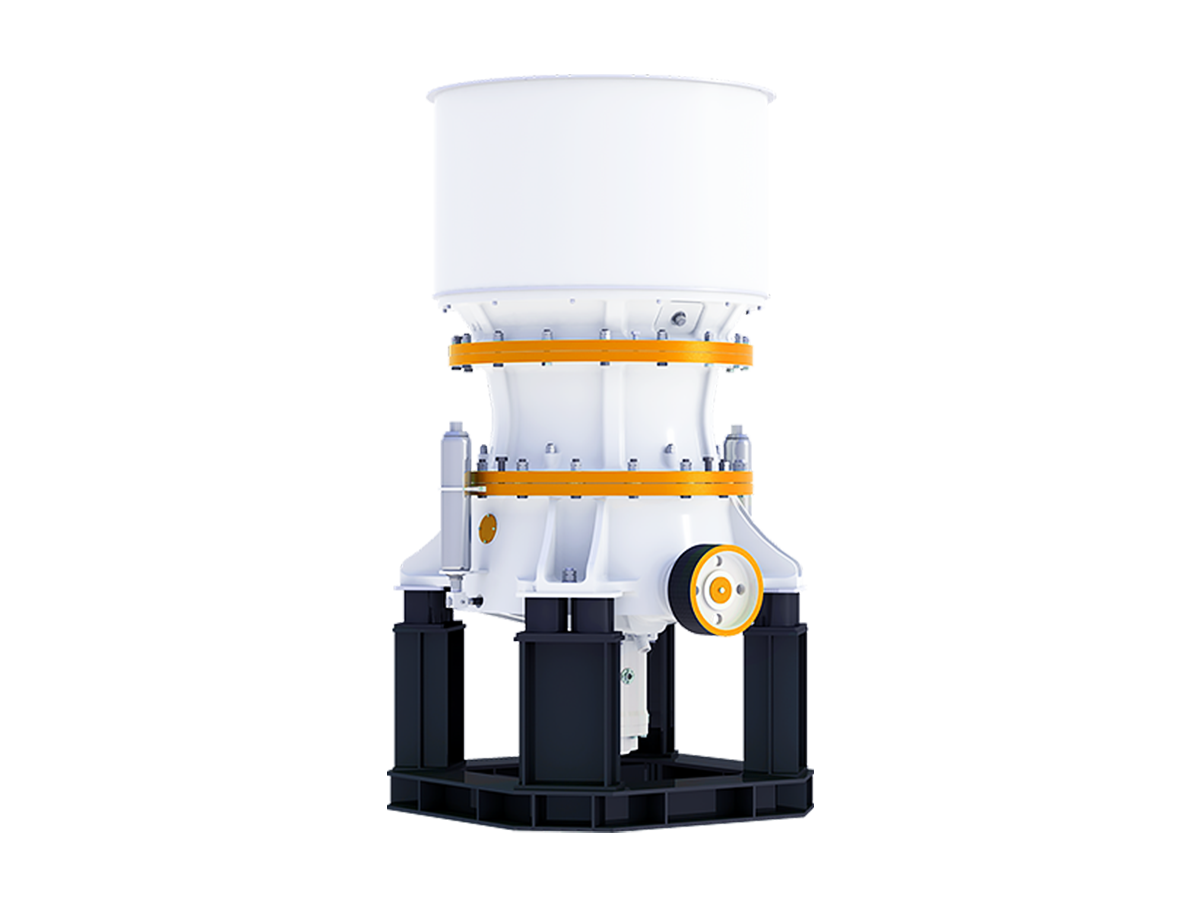

With advanced technology,HD series single cylinder hydraulic cone crusher has several cavity types,which meets the different requirements of the clients.Owing to the hydraulic technology of this series cone crusher,overload protection can be realized,which simplifies the structure and lightens the weight of the crusher.All the repair and inspection work can be done from the upper part of the cone crusher,therefore,it is easy to maintain this machine.

| 型号Model | 腔型腔型Cavity type | 入料尺寸 Feed size(mm) |

排矿口调节范围Adjustment range of discharge outlet(mm) | 处理能力 Capacity(t/h) |

功率 Powe(kw) |

| HD100 | coarse | 200 | 20-50 | 80-190 | 75-90 |

| Medium coarse | 150 | 16-40 | 60-125 | ||

| Fine | 50 | 10-30 | 40-100 | ||

| HD200 | coarse | 250 | 20-70 | 160-280 | 132-160 |

| Medium coarse | 220 | 16-50 | 120-230 | ||

| Fine | 70 | 10-30 | 100-210 | ||

| HD300 | coarse | 300 | 30-80 | 260-500 | 220-250 |

| Medium coarse | 240 | 20-60 | 200-350 | ||

| Fine | 100 | 16-30 | 150-250 | ||

| HD400 | coarse | 400 | 35-100 | 350-600 | 250-315 |

| Medium coarse | 300 | 25-70 | 260-450 | ||

| Fine | 145 | 18-40 | 180-300 | ||

| HD500 | coarse | 500 | 40-120 | 480-800 | 280-355 |

| Medium coarse | 350 | 30-80 | 320-700 | ||

| Fine | 200 | 20-50 | 200-500 |

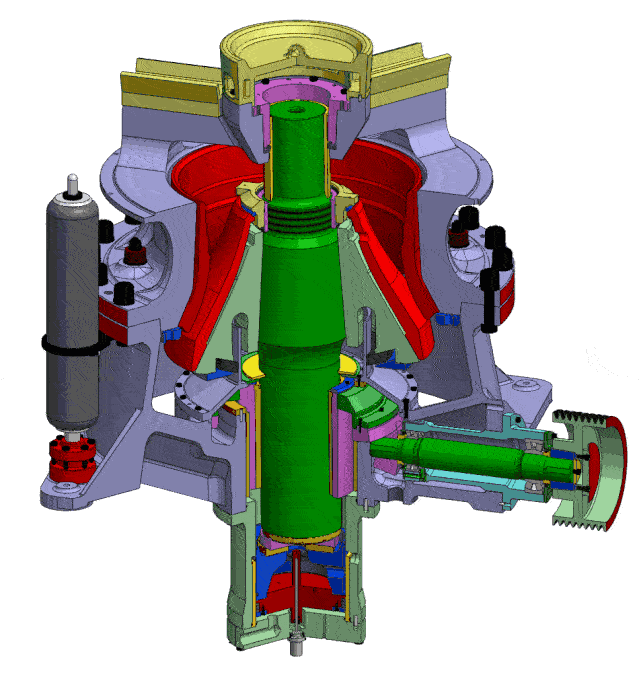

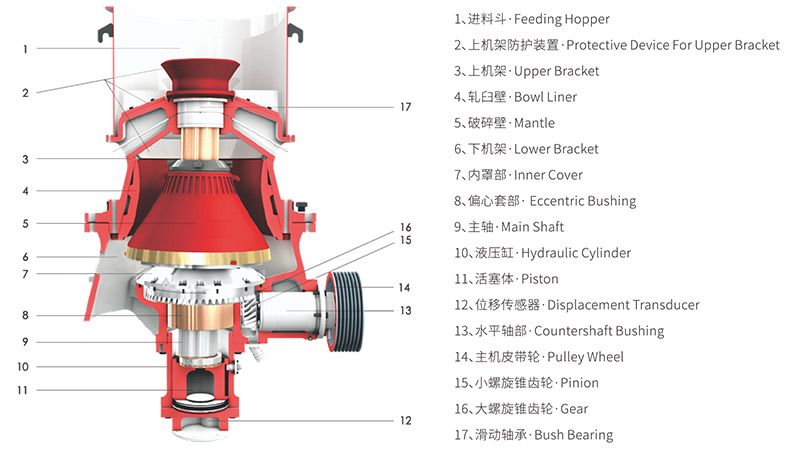

The crushing process follows a simple principle: feed material enters the crushing chamber, where the mantle—a rotating component—gyrates in an eccentric motion. Unlike a perfect rotation, the mantle moves in a slight swing pattern, constantly changing the gap between itself and the fixed concave (the stationary outer ring). As the mantle swings, it crushes the material against the concave at the narrowest gap points. The feed material also undergoes interparticle crushing, meaning rocks compress against each other during the process.

A cone crusher consists of key parts including the main shaft, mantle, bowl liner, concave, eccentric bushing, and drive mechanism.

优势Advantages

High efficiency: Combines advanced chamber design and high crushing frequency, reaching up to 2181 tons per hour.

Better product shape: Uses intergranular lamination crushing to produce cubic-shaped final products with fewer needle-like particles.

Easy maintenance: Components are easily removed from the top. Filler-free liners save replacement time and costs.

Low downtime: Equipped with hydraulic and lubrication systems for dual protection, it handles overloads automatically and ensures continuous operation, reducing downtime.

Dust protection: Positive pressure system blocks dust and debris, keeping parts clean and extending service life.

Smart automation: Features an intuitive interface for quick discharge adjustment and precise size control. Automation boosts productivity by 15%-25%, simplifying complex operations.