- output:200t/h

- Feed size:150mm

- Motor power:160KW

High-efficiency hydraulic cone crusher machine has a variety of crushing cavity types to meet the diverse needs of users. The products are popular among users. They are widely used in mines, railways, highways, building materials, and chemicals. They are often used for crushing ores in stone production lines.

| 型号 Model | 腔型 Type of cavity |

最小排料口 Min output(mm) |

给料口尺寸 Feed opening size(mm) |

生产能力Capacity(t/h) | 电机功率Motor power(kw) | 动锥直径Moving cone diameter(mm) |

| HPY200 | C | 13 | 150 | 100-240 | 160 | 950 |

| F | 6 | 76 | 55-180 | |||

| HPY300 | C | 13 | 225 | 150-300 | 220 | 1160 |

| F | 6 | 86 | 90-240 | |||

| HPY400 | C | 13 | 290 | 190-400 | 315 | 1400 |

| F | 6 | 100 | 108-300 | |||

| HPY500 | C | 13 | 320 | 260-500 | 400 | 1500 |

| F | 6 | 110 | 145-350 | |||

| HPY800 | C | 13 | 350 | 325-800 | 630 | 1800 |

| F | 8 | 120 | 245-450 |

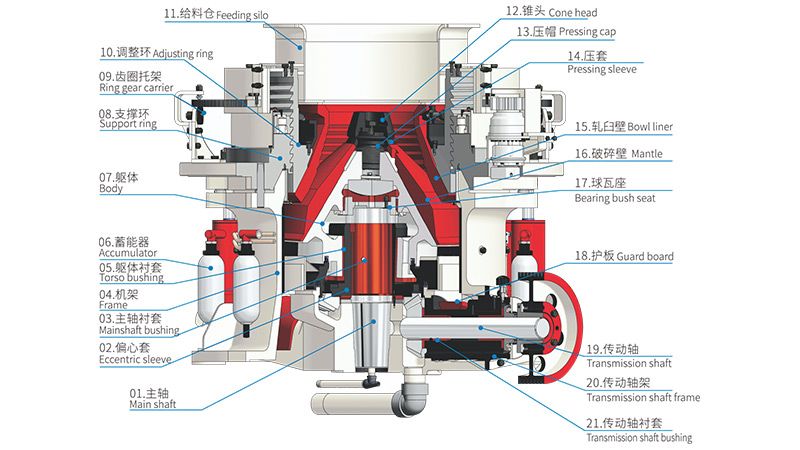

The structure of the multi-cylinder hydraulic cone crusher is more complicated. When working, the motor drives the transmission shaft through the pulley or coupling. The moving cone does periodic rotation-swing movement under the force of the eccentric sleeve. The raw materials are squeezed, impacted, and finally broken in the crushing chamber.

Multi-cylinder hydraulic cone crusher structure is relatively complex, a total of eleven parts, namely: fixed cone, moving cone, fixed central shaft, sphere tile, adjustment ring, eccentric, fan gear and pinion, horizontal axis, surrounding hydraulic cylinders, hydraulic station, lubrication station.

优势Advantages

1/ High crushing efficiency. It adopts the optimal structure of fixed spindle and small spherical axis, the efficiency is 5%-15% higher than the spring cone crusher.

2/Super strong production capacity. The perfect combination of crushing stroke, crushing speed and crushing cavity make its yield 35% - 60% higher than common cone crusher.

3/Perfect finished particles. Using the unique principle of multi-layers crushing, the ratio of cubic particles in the finished product is obviously increased, the flakiness particles are reduced, and the grade is more reasonable.

4/Advanced lubrication mechanism. Multi- point hydraulic lubrication control system can ensure that the equipment bearing lubrication double protection and overload protection.