- output:35t/h

- Feed size:

- Motor power:55kw

Hammer crusher can be divided into single-rotor (single-axis)and double rotor (biaxial).Single rotor can be divided into two types:reversible and ireversible.According to hammer rows,it can be divided into single row and multiple rows.It is used in cement,chemical,electric power,metallurgy and other industrial sectors for crushing limestone,slag,coke,coal and other medium hardness materials.

| 型号规格Model | 给料粒度Input size(mm) | 出料粒度Output size (mm) | 产量Capacity(t/h) | 功率Powerkw) | 重量Weight(t) |

| PC300×200 | ≤50 | ≤10 | 1-2 | 5.5 | 0.4 |

| PC 400×300 | ≤100 | ≤10 | 5-10 | 11 | 0.8 |

| PC 600×400 | ≤120 | ≤15 | 10-25 | 22 | 1.5 |

| PC 800×600 | ≤120 | ≤15 | 20-35 | 55 | 3.1 |

| PC 1000×800 | ≤200 | ≤13 | 20-40 | 75 | 7.9 |

| PC 1000×1000 | ≤200 | ≤15 | 30-80 | 90 | 8.65 |

| PC1200×1000 | ≤250 | ≤19 | 80-200 | 132 | 13.6 |

The hammer and the rotor are rigidly connected, and the inertia of the entire rotor is used to impact the material (free crushing, impact crushing, milling crushing), so that it not only crushes but also obtains greater speed and kinetic energy. The board hammer is to greet the input material from bottom to top for impact crushing, and throw it onto the upper counterattack board.

The hammer head of the hammer breaks the material by a single blow (free crushing, counter-attack crushing), and the speed and kinetic energy obtained by the material are limited. The hammer head strikes the material along the direction in which the material falls, with little crushing effect.

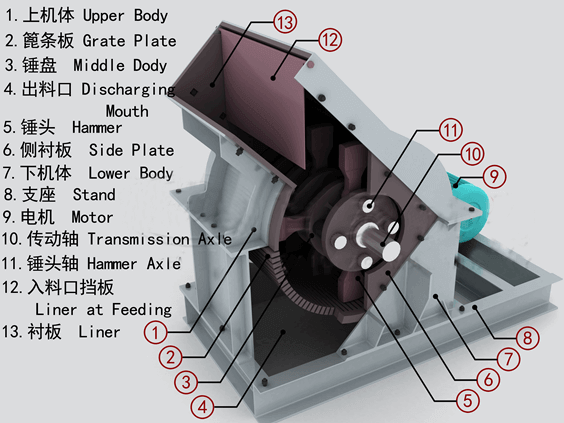

The hammer is composed of rotor, hammer head, hammer frame, pin shaft, frame, crushing plate, screen plate, transmission parts, etc. The hammer head is hinged on the hammer frame.

优势Advantages

1.Inlet large, high crushing chamber.

2. Broken power consumption low.

3. New hammer, impact force.

4. Hammer shaft mounted adjustable, hammer, long life.

5. Grid size is adjustable, controllable particle size, particle shape is good.

6. Chassis can be flipped, maintenance more convenient.

7. Square shank bolts, impact resistance, wear and tear.

8. Compact, machine rigidity.

9. Fight structure, handling, easy to install.