- output:

- Feed size:

- Motor power:11kw

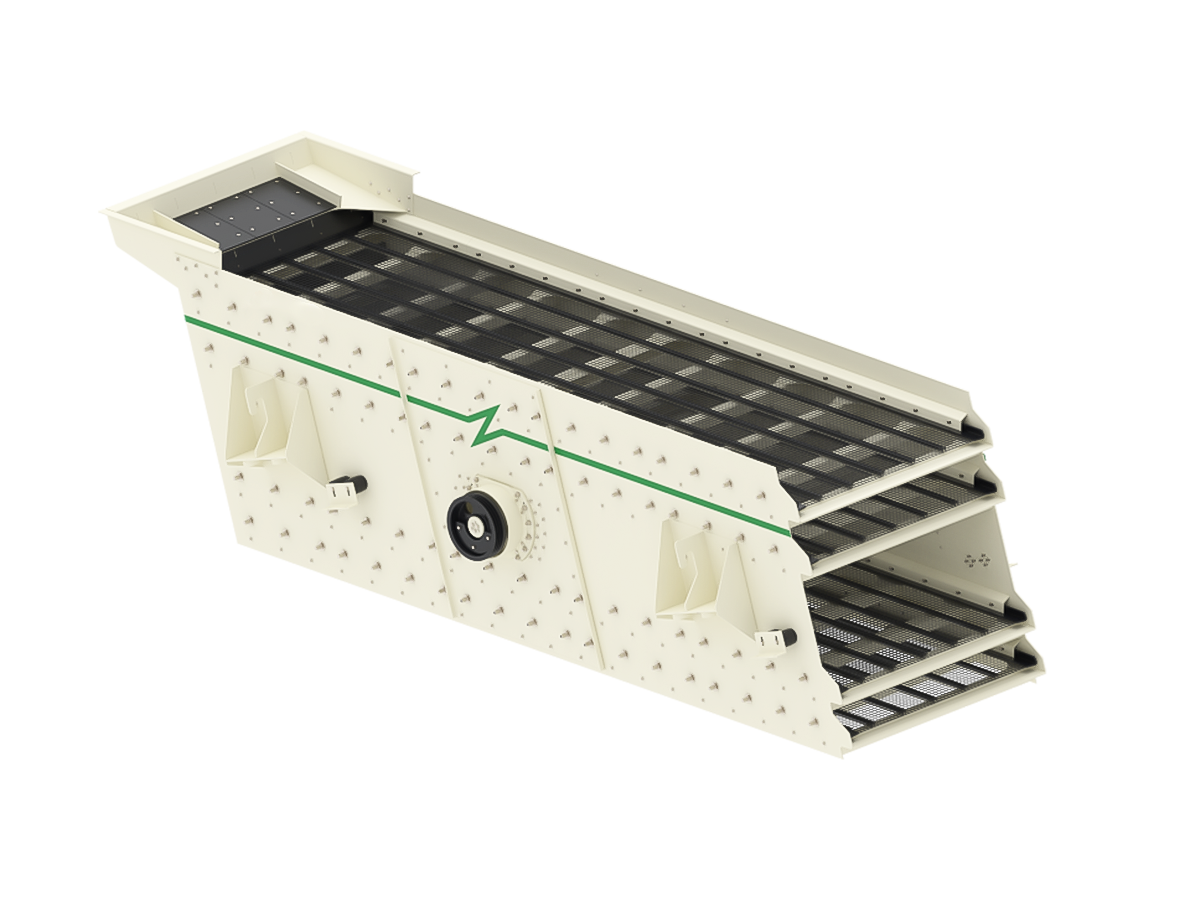

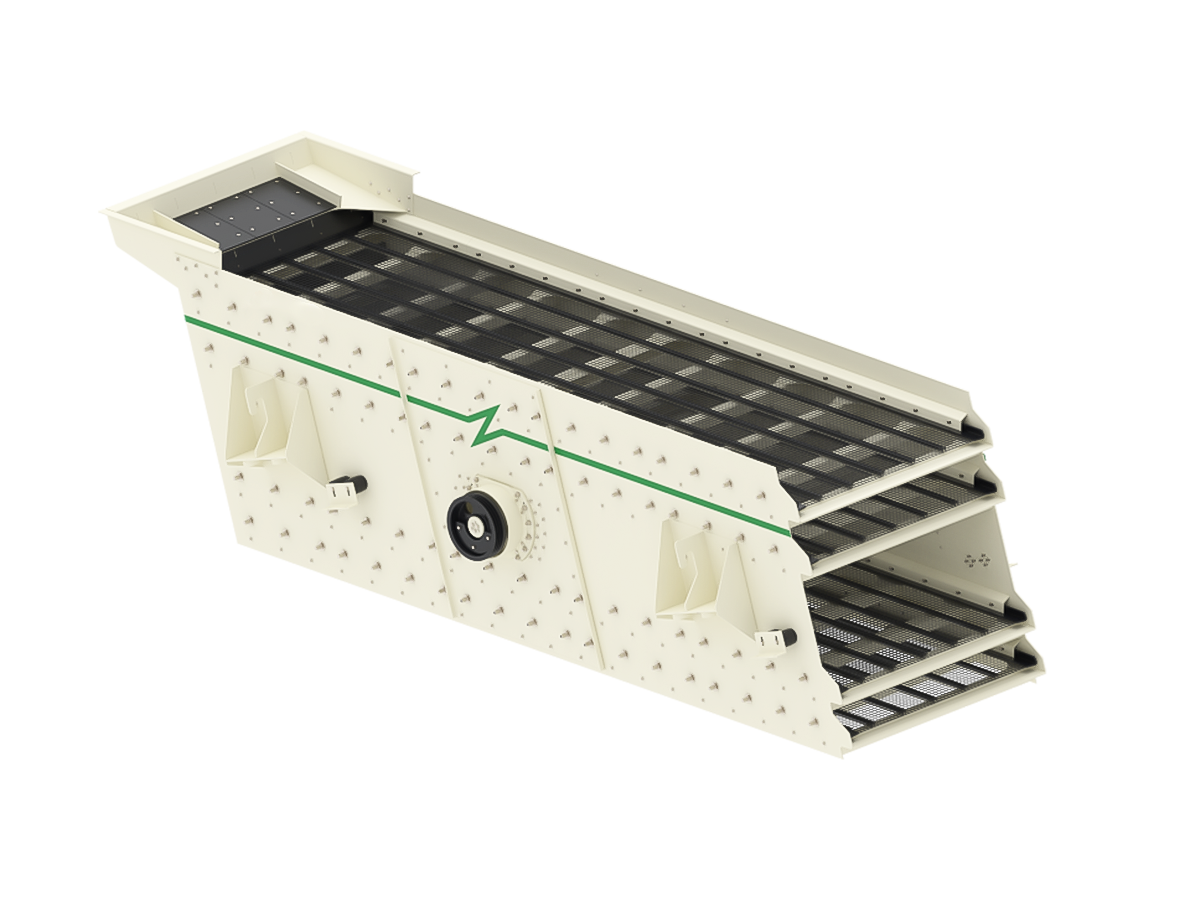

Circular vibrating screen has multiple layers,it is a multi-layer,high efficiency new vibrating screen.It has characteristics like reliable structure,low consumption,high screening efficiency,low vibrating noise,long durability,convenient maintenance,safe operation,etc.Our vibrating screen is widely used for screening in mines,building material,transportation,energy sources,chemical industry,etc.

| 型号 Model | 筛面层数 Layers | 筛孔尺寸 Screen mesh(mm) |

最大进料尺寸 Max feed size(mm) | 处理能力Capacity(m³/h) | 振动频率 Frequency (r/min) | 双振幅(mm)Double amplitude | 电机功率(kw) Motor power |

重量(不含电机) Weight(t)(Excluding motor) |

筛面倾角(") Screen slope |

筛面规格(mm) Screen specification |

| 2YK1237 | 2 | 2-50 | 200 | 25-50 | 970 | 8 | 11 | 4.9 | 15-20 | 1200×3700 |

| 3YK1237 | 3 | 2-50 | 200 | 30-60 | 970 | 8 | 11 | 5.2 | 15-20 | 1200×3700 |

| 4YK1237 | 4 | 2-50 | 200 | 30-60 | 970 | 8 | 11 | 5.3 | 15-20 | 1200×3700 |

| 2YK1548 | 2 | 2-50 | 200 | 45-90 | 970 | 8 | 15 | 6.3 | 15-20 | 1500×4800 |

| 3YK1548 | 3 | 2-50 | 200 | 45-90 | 970 | 8 | 15 | 6.5 | 15-20 | 1500×4800 |

| 4YK1548 | 4 | 2-50 | 200 | 45-90 | 970 | 8 | 18.5 | 6.6 | 15-20 | 1500×4800 |

| 2YK1848 | 2 | 2-50 | 200 | 55-110 | 970 | 8 | 15 | 6.9 | 15-20 | 1800×4800 |

| 3YK1848 | 3 | 2-50 | 200 | 55-110 | 970 | 8 | 22 | 7.2 | 15-20 | 1800×4800 |

| 4YK1848 | 4 | 2-50 | 200 | 55-110 | 970 | 8 | 22 | 7.5 | 15-20 | 1800×4800 |

| 2YK1860 | 2 | 2-50 | 200 | 65-130 | 970 | 8 | 22 | 7.1 | 15-20 | 1800×6000 |

| 3YK1860 | 3 | 2-50 | 200 | 65-130 | 970 | 8 | 22 | 7.4 | 15-20 | 1800×6000 |

| 4YK1860 | 4 | 2-50 | 200 | 65-130 | 970 | 8 | 30 | 7.7 | 15-20 | 1800×6000 |

| 2YK2160 | 2 | 2-50 | 200 | 80-160 | 970 | 8 | 30 | 11.2 | 15-20 | 2100×6000 |

| 3YK2160 | 3 | 2-50 | 200 | 90-180 | 970 | 8 | 37 | 12.4 | 15-20 | 2100×6000 |

| 4YK2160 | 4 | 2-50 | 200 | 90-180 | 970 | 8 | 45 | 15.1 | 15-20 | 2100×6000 |

| 2YK2460 | 2 | 2-50 | 200 | 150-300 | 970 | 8 | 30 | 13.5 | 15-20 | 2400×6000 |

| 3YK2460 | 3 | 2-50 | 200 | 180-360 | 970 | 8 | 37 | 13.6 | 15-20 | 2400×6000 |

| 4YK2460 | 4 | 2-50 | 200 | 180-360 | 970 | 8 | 45 | 14.4 | 15-20 | 2400×6000 |

vibrating screen mainly consists of the eccentric block vibrator, screen box, motor, and supportive device. Its vibrating track is a circle and moves on a circular motion. It is a multi-layer and high efficient vibrating screen.

Motor drives the V-belt to make the eccentric block rotate in high speed, so that producing large centrifugal force to make exciter produce the amplitude in circular motion, the stone aggregates on the screen surface will be throwing motion continuously under the function of exciter, during the process of materials contacting with the screen surface, final products will be classified.

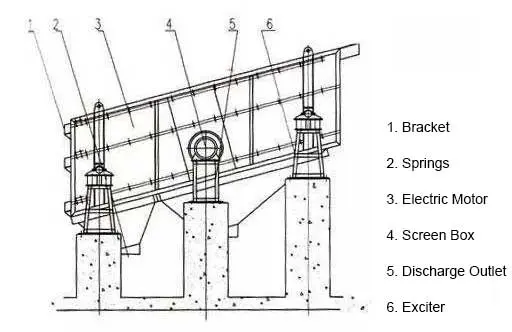

The circular vibrating screen is composed of a screen box, screen frame, screens, transmission device, vibration exciter, supporting device, vibration-isolating device, etc.

Screens: the screen is fixed on the screen bracket by bolts and rubber strips. Because it is mainly used to screen large-sized materials, the screen surface needs to have a greater bearing capacity, wear resistance, and impact resistance.

Screen frame: the screen frame is composed of side plates and beams. The side plate can be made of steel plate or other materials. The beam is usually made of steel pipe, channel steel, or I-beam.

Vibration exciter: circular vibrating screen adopts single shaft exciter.

Supporting device: it is an elastic element for supporting the screen box, including a hanging type and seat type.

Vibration-isolating device: it prevents the vibration from being transmitted to the ground, commonly used are coil springs, plate springs, and rubber springs.

Transmission device: circular vibrating screen frequently adopts a V-belt transmission device. It has a simple mechanism and steady running.

优势Advantages

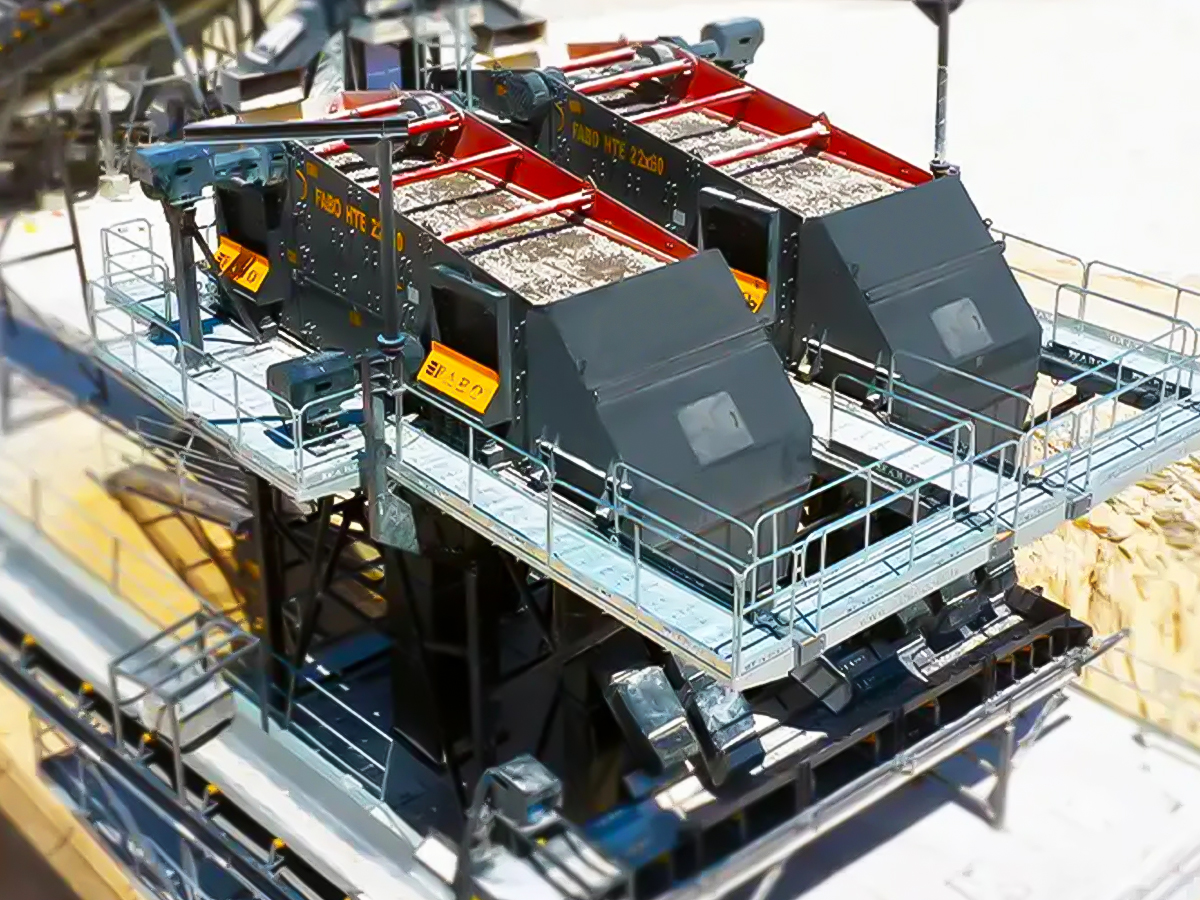

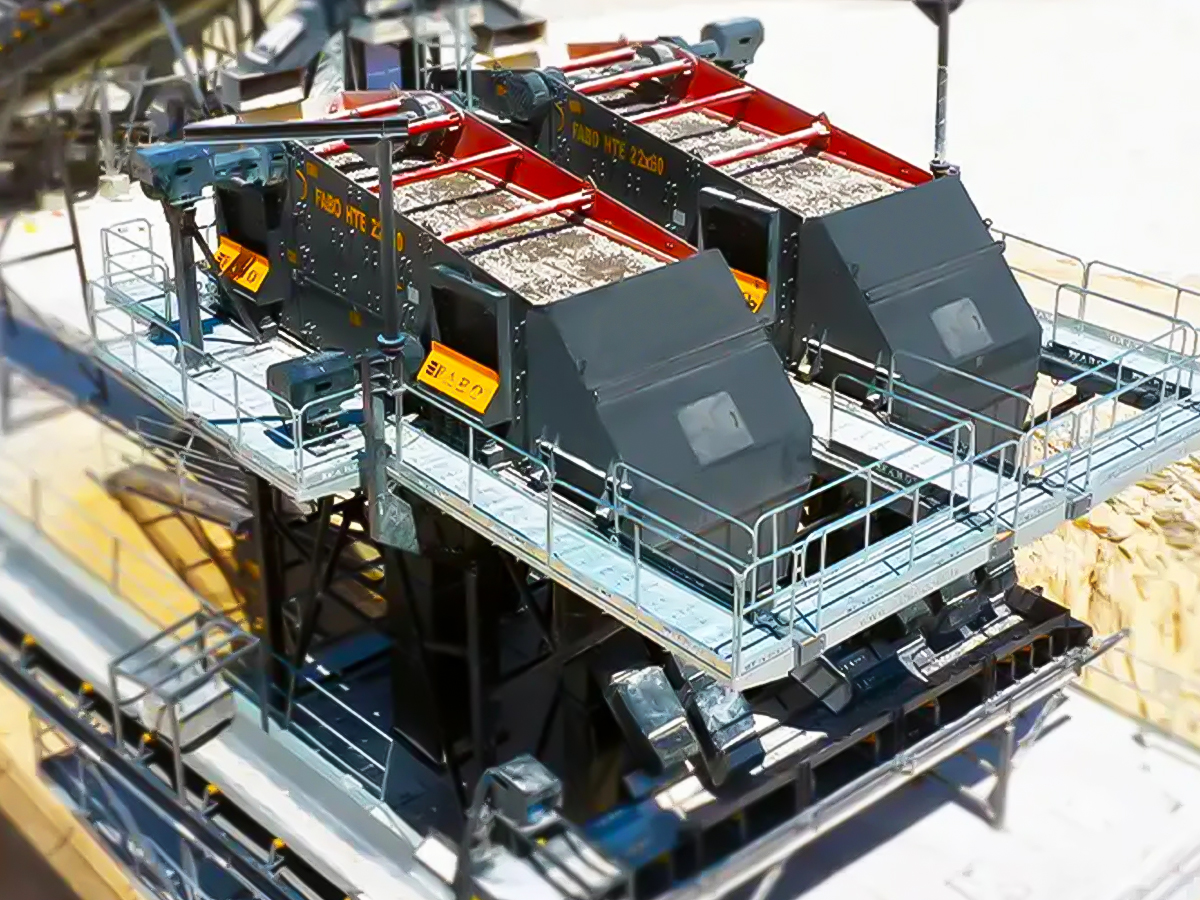

01.Configurable Screening Media

Compatible with wire mesh, perforated sheets, and polyurethane panels for application-specific performance.

02.High Compression Springs

Heavy-duty springs absorb dynamic loads, ensuring stable operation and extended equipment life.

03.Modular Drive System

Independent bearing modules linked by a cardan shaft ensure balanced vibration and easy maintenance.

04.Wet Screening Applications

Integrated spray bars enhance material washing and efficiency in wet screening setups.