- output:0.3-2.5t/h

- Feed size:0.037-2mm

- Motor power:1.1kw

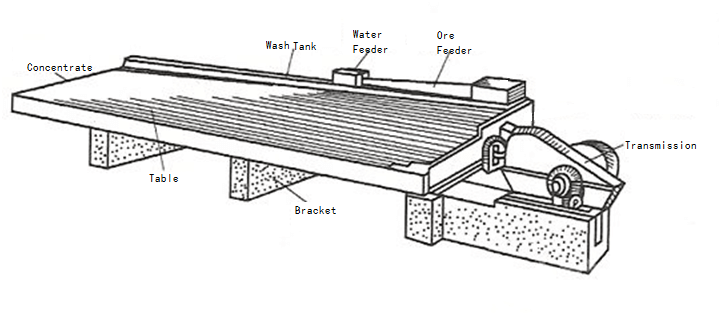

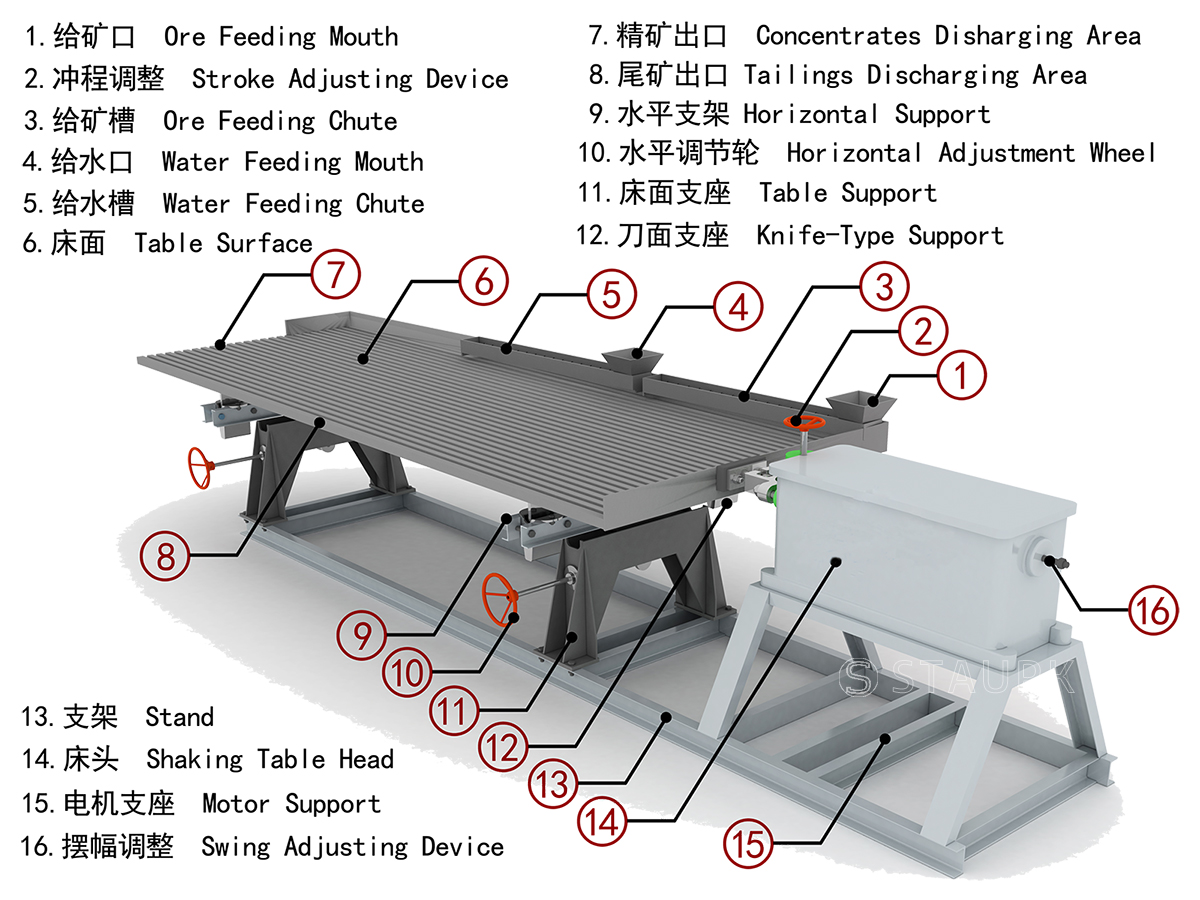

6-S shaking table is one of important equipment in gravity beneficiation process,which is applied in iron, manganese,coal,tungsten,tin,gold and other rare metal and precious metal beneficiation process.It can be used for roughing,concentrating,scavenging process to extract different particle ore,such as rough sand, fine sand and ore mud.

| Model No | 6-S | Surface size of table (mm) | 4520×1850×150 | |

| Stroke(mm) | 8-36 | Motor (kw) | 1.1 | |

| Stroke rate(Time/Min) | 240-380 | Overall imensions(mm) | 5630×1850×900 | |

| Landscape angle(°) | 0-5 | Surface Weight of table(kg) | 650 | |

| Material | Feed size(mm) | Mine density | Flushing water(t/h) | Capacity(t/h) |

| Coarse sand | 0.5-2 | 10-30 | 0.5-3.5 | 1-2.5 |

| Fine sand | 0.074-0.5 | 10-30 | 0.5-3.5 | 0.8-1.2 |

| Ore mud | 0.037-0.074 | 10-30 | 0.5-3.5 | 0.3-0.6 |

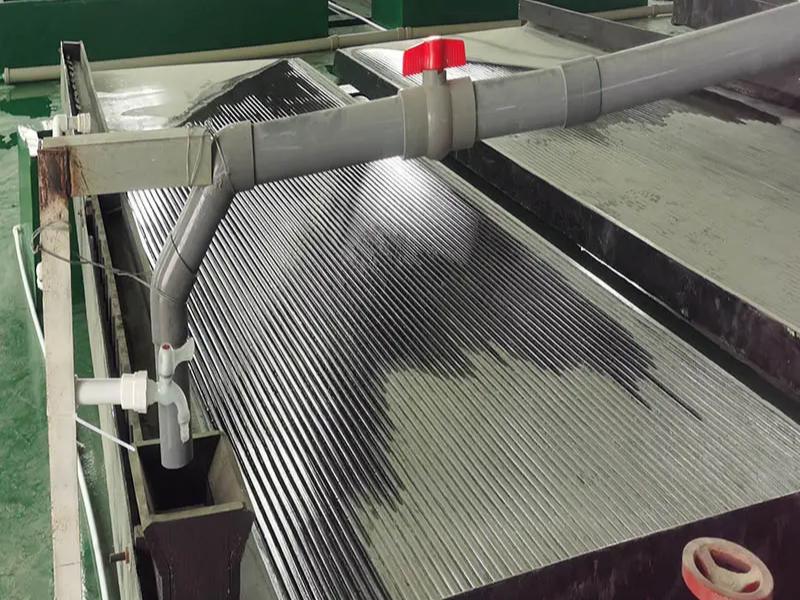

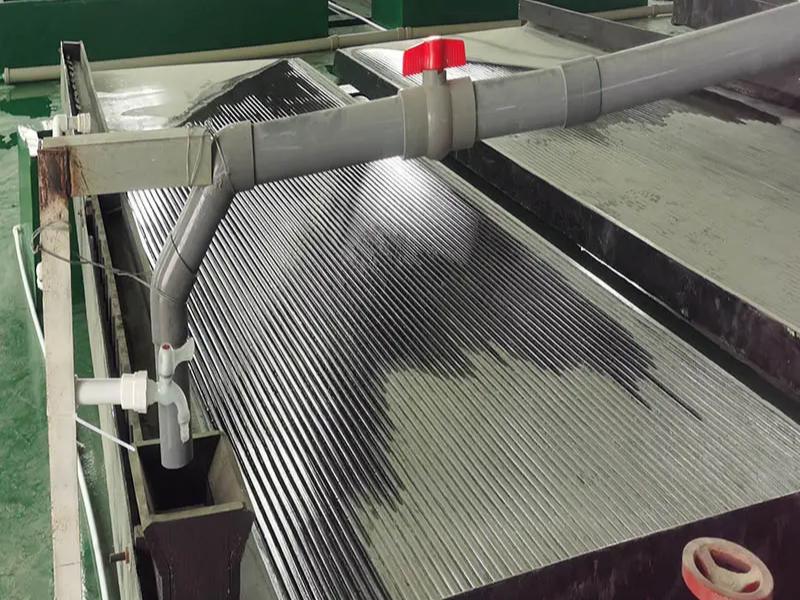

Shaking tables are rectangular-shaped tables with ribbed decks with a water film flowing on them. Water flowing along the long axis of the table slurries the fed sample. Low-density particles are transported in the fast-moving film, causing fine, high-density particles to fall into the beds behind rifles. With the rapid backward movement of the table, the particles gain a forward movement thanks to momentum, so each structure is separated from the other. Separation performance in shaking tables is directly related to particle size distribution.

Therefore, the narrower the grain size of the material, the better the separation performance. Wilfley and Gemini type shaking tables appear with different models in the recovery of precious metals, in gold mines, and in electronic waste recycling processes.

The crankshaft rocker moves up and down as shaking table’s belt rotating drove by motor. When the crankshaft rocker moves downward, materials will come in from tilt table though bunker. The water channel of shaking table supplies water to the materials. Like this, while the table is vibrating, the water is flowing. Different density materials will flow to concentrate mouth and tails mouth along with different direction. Mining shaking table has improved much after generations.

Advantages

High Separation Accuracy: The shaker table can effectively separate minerals with different specific gravities and obtain high-purity concentrates.

Easy Operation: Simple operation and maintenance, requiring no complex training.

Low Cost: Compared with other beneficiation equipment, the shaker table has a lower investment cost and operating cost.

Wide Application: The shaker table is suitable for the beneficiation of various minerals, such as gold, silver, copper, lead, zinc, tungsten, tin, etc.

Environmentally Friendly: The shaker table is a physical beneficiation method that does not use chemical reagents and causes less environmental pollution.