- output:6-395m³

- Feed size:<2-Ø133

- Motor power:2.2-30kw

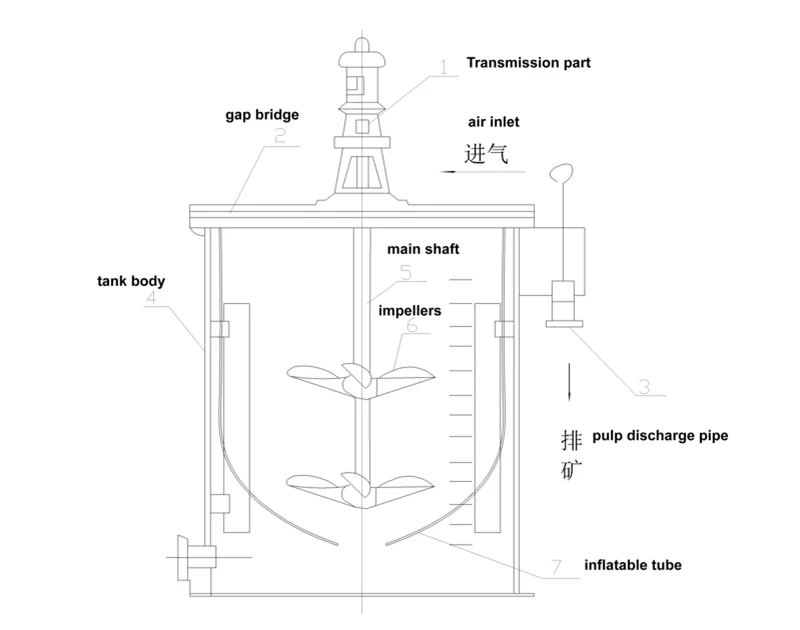

The double impellers leaching tank,is used for stiring,leaching and carbon absorption in the gold cyanide plant .as usual,the ore pulp in the double impellers leaching tank should have the fineness 75%of 200 mesh at least and the pulp density is less than 45%.

The working principle of double impellers leaching tank is that under the action of impeller,the pulp flow from top to bottom in the center,spread from surrounding damping plate,then mixed with the air fed from the lower.

| 型号 Model | 槽体规格(mm) (直径×高度) Cell(diameter×Height) |

有效容积 Effective Volume (m³) |

叶轮 Impeller | 直径Impeller (mm) |

行星摆线减速器 Cyclical Planetary Reducer |

重量 Weight(kg) |

|||||

| 转速 Rotation Speed(rpm) |

直径 Diameter (mm) |

给矿管 Feeding Tube |

排矿管 Output Tube |

型号 Model | 速比 Ratio |

配用电机功率 Motor Power(kw) |

槽体重量 Cell Weight |

总重 Total Weight |

|||

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2-Ø133 | 2-Ø133 | XLD2.2-4-29 | 29 | 2.2 | 1609 | 2144 |

| SJ2.5×3.15 | 2500×3150 | 13 | 52 | 935 | 2-Ø125 | 2-Ø125 | XLD2.2-4-29 | 29 | 2.2 | 2398 | 3095 |

| SJ3×3.15 | 3000×3150 | 18.9 | 43 | 1130 | 2-Ø150 | 2-Ø150 | XLD4-5-35 | 35 | 4 | 2480 | 4160 |

| SJ3.55×4.0 | 3550×4000 | 35 | 43 | 1310 | 2-Ø150 | 2-Ø150 | XLD4-5-35 | 35 | 4 | 4260 | 5025 |

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 2-Ø150 | 2-Ø150 | XLD7.5-7-43 | 43 | 7.5 | 6397 | 7569 |

| SJ4.5×5.0 | 4500×5000 | 71.6 | 35 | 1750 | 2-Ø159×6 | 2-Ø159×6 | XLD7.5-7-43 | 43 | 7.5 | 8614 | 10864 |

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 2-Ø159×8 | 2-Ø159×8 | XLD11-8-47 | 47 | 11 | 8740 | 14291 |

| SJ5.5×6.0 | 5500×6000 | 112 | 31 | 2100 | 2-Ø159×8 | 2-Ø159×8 | XLD11-8-47 | 47 | 11 | 12467 | 18745 |

| SJ6.5×7.0 | 6500×7000 | 215 | 21 | 2400 | 2-Ø159×8 | 2-Ø159×8 | GRF147-Y22-4P-70.87 | 47 | 22 | 17890 | 25978 |

| SJ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 2-Ø159×8 | 2-Ø159×8 | XLD22-10-47 | 47 | 22 | 20505 | 29030 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 23 | 2900 | 2-Ø168×8 | 2-Ø168×8 | XLD22-10-47 | 47 | 22 | 22552 | 32796 |

| SJ8.0×8.5 | 8000×8500 | 342 | 18.5 | 3300 | 2-Ø168×8 | 2-Ø168×8 | TPS315-3F | 59 | 30 | 30559.5 | 42467.3 |

| SJ8.5×9.0 | 8500×9000 | 395 | 18.5 | 3300 | 2-Ø219×8 | 2-Ø219×8 | TPS315-3F | 59 | 30 | 34130 | 46623 |

Agitation leaching Tank for a variety of metal ores, mainly for pre-mixing flotation, are pharmaceutical products, with the well-mixed slurry can also be used for other non-metallic mineral mixing.It is a flat-bottomed bucket of radiation in the form of circular screw-type impeller mechanical agitation.Triangle by the electric motor rotating impeller rotation, will be full of drugs and pulp mixture to increase the role of the mineral reactions pharmaceutical and strengthen drug reactions necessary equipment.

The series leaching tank is suitable for less density,low viscosity,low sedimentation velocity,more than 90% particle size in the -200 mesh,in the gold leaching,adsorption and other mixed operation of slurry concentration is less than 45% (by weight).Without crushing materials for the easy crushed materials,it is more superiority to adopting this machine.

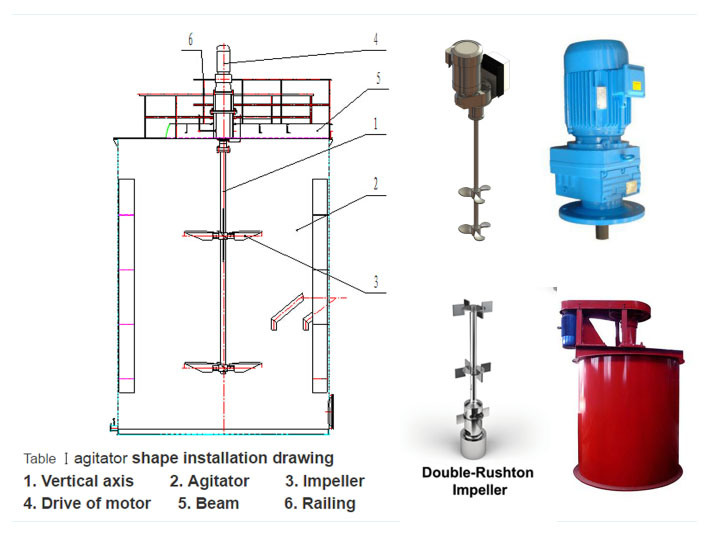

Double impeller leaching tank equipped with motor, cycloidal planetary gear speed reducer, bearing block and agitating shaft, is characterized by compact structure, little occupied space, and the agitating shaft equipped with a double impeller , from the top view the impeller rotating clockwise, each impeller composed of 4 blades, and the angle of the top blade and the below one is 45 degree. The compact air gets through the elbow pipe or the hollow shaft to the tank’s bottom, the raising air plays the role of mixing , at the same time the big bubble shattered by the impeller changing into small bubbles, in the end the pulp and air reaches fully mixing and sodium cyanide solution contacts with the pulp completely, thereby gets the better gold leaching result. The design of this device keeps the impeller low-speed moving, reducing the possibility of wearing or smashing the active carbon, so as to achieve high leaching rate, high absorption rate and collects more gold.

Advantages

The flow of the ore stream is stable, the slurry is mixed uniformly, and the power consumption is low.

The air enters the groove through the hollow shaft of the transmission, and is agitated by the blades, so that the air is evenly dispersed.

Compact structure and easy maintenance.

The hollow shaft is ventilated to the bottom, and air enters the tank through it, dispersed evenly with small bubblesv

Using two new impellers, the diameter of the impeller of the stirring tank is large, the rotation speed is low, and the power consumption of the stirring is small, which can reduce the wear of the char.

The stirring intensity is moderate, and the concentration and fineness distribution of the slurry in the tank are consistent, which can improve the leaching rate of cyanide and the adsorption rate of carbon.

The impeller of the leaching mixing tank is lined with wear-resistant rubber, which has a low speed and a long service life.