Temperature of desorption is 120±10℃,operation pressure 0.2±0.1MPA,temperature of e

- output:150-1500Kg/Batc

- Feed size:/

- Motor power:34.4-89kw

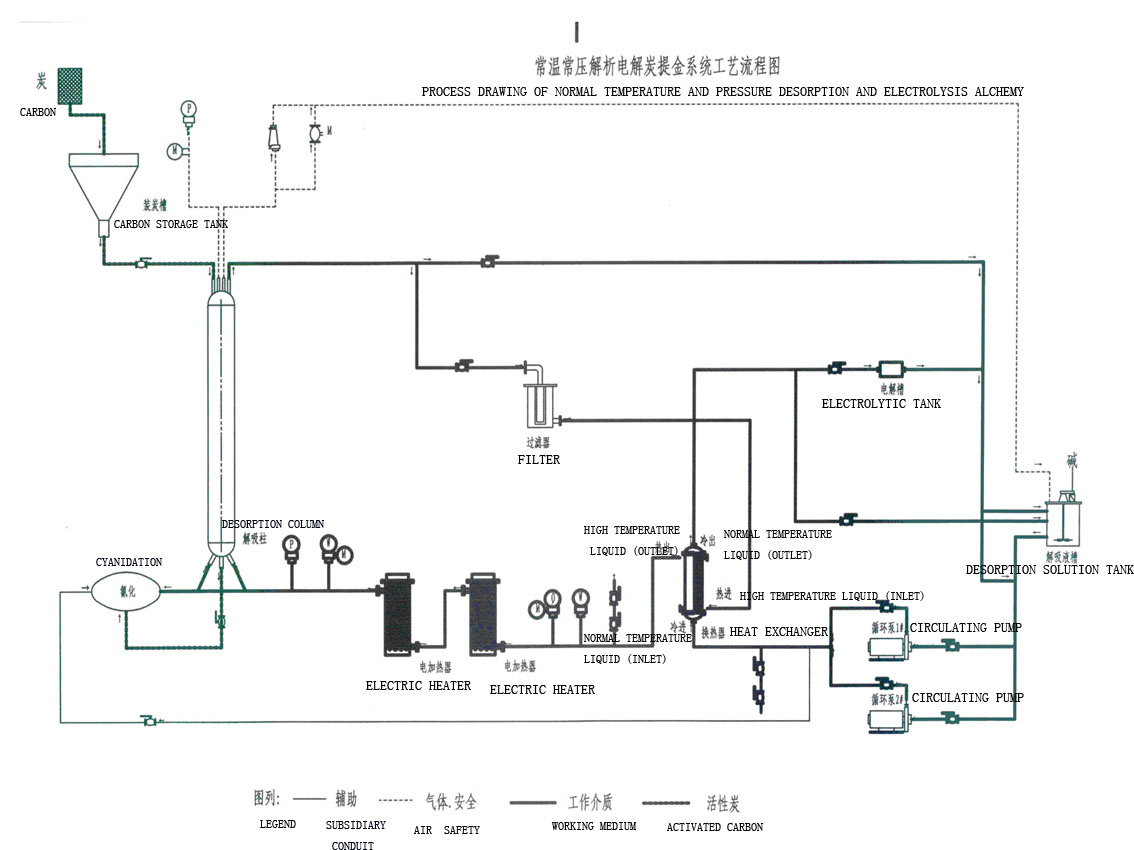

Normal temperature and normal pressure desorption electrolysis equipment is composed by electric heater, elution column,heat exchanger,electrolyzer,pump and etc.

Temperature of desorption is 120±10℃,operation pressure 0.2±0.1MPA,temperature of electrolysis is 90- 98℃,Processing time of Gold Loaded Carbon is 30-36 hours/batch,and also the desorption liquid need to add certain sodium cyanide.

| 载金炭处理能力 (kg/批次) Processing Capacity of Gold Loaded Carbon(Kg/Batch) |

工 作 压 力 ( M P a ) Operate Pressure |

工作温度(℃) Desoption Temperature |

功率(Kw) Power |

贫炭品位(g/t) Grade of Lean Carbon |

| 150 | 0.2±0.1 | 120±10 | 34.4 | <200 |

| 300 | 0.2±0.1 | 120±10 | 34.4 | <200 |

| 500 | 0.2±0.1 | 120±10 | 66 | <200 |

| 1000 | 0.2±0.1 | 120±10 | 89 | <200 |

| 1500 | 0.2±0.1 | 120±10 | 89 | <200 |

The system employs a two-stage process: desorption and electrolysis.

Desorption: Activated carbon, with its affinity for anions, is introduced into the system to replace the Au(CN)2- complex, thereby desorbing gold. This process occurs in a desorption tower.

Electrolysis: The gold-laden solution from the desorption stage is transferred to an electrolytic cell. Here, ionization is utilized to recover solid gold. The crude gold produced undergoes further purification to yield finished gold.

In essence, the system involves desorbing gold from the carbon using a specific chemical environment and then recovering the gold through electrolysis.

Advantages

High efficiency gold recovery

Low consumption of resources

Rapid desorption electrolysis process (approximately 12 hours)