- output:1-3000t/d

- Feed size:2-8g/t

- Motor power:0

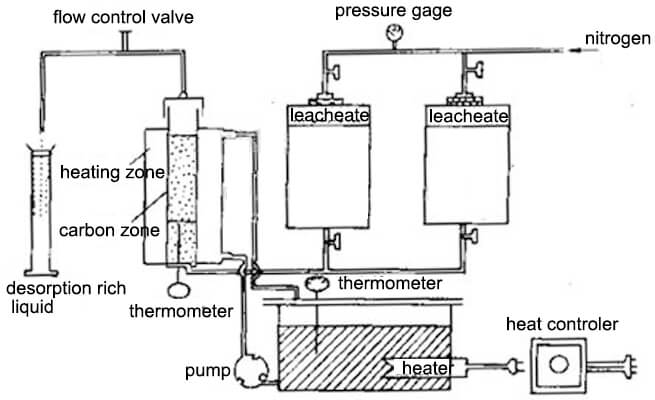

A system for desorbing and electrowinning gold from a gold-bearing charcoal under high temperature and high pressure conditions.The advantage is that under the condition of high temperature and high pressure,the desorption rate is above 98%;the desorption electrolysis temperature is the same,no heat exchange is needed,and the power consumption is 1/4~1/2 of the conventional system due to rapid work; the non-toxic desorption combination agent Carbon- containing activator,which plays a role in regeneration of charcoal,does not require fire regeneration,saves carbon regeneration cost;has low cyanide cost and no pollution;high grade gold mud,no need for reverse electrolysis,easy to extract.

| Model | Suitable size | system equipment details | System instrument details | Operating parameter | |

| Mine capacity (t/d) |

Ore grade (g/t) |

||||

| GJD-200 | <150 | 2-8 | S1 desorption column S2 filter S3 electrolytic cell S4 circulation pump S5 electric heater S6 ejectorS7 air compressor S8 desorption tank S9 clean water pump S10 acid storage tank S11 magnetic pump S12 carbon storage tank S15 control cabinet S16 silicon rectifier cabinet S17 pickling tank |

B1 resistance remote diaphragm pressure gauge B1 pressure indicating regulator B2 diaphragm pressure gauge B3 vortex flowmeter B3 flow totalizer B4 thermal temperature gauge B5 temperature sensor B5 temperature indicating regulator B6 diaphragm pressure gauge B7 level gauge B9 temperature sensor B9 temperature indicating regulator |

Desorbent PH>13.5 Use batch: unlimited Electrolysis start 100-110℃ End of electrolysis: 150℃ Electrolytic current. 350-1250 A Electrolysis voltage: 2-4V Pressure at 150 C: desorption column Upper part: 0.50-0.57 MPa Electrolytic tank: 0.45-0.52 MPa |

| GJD-300 | 150-300 | ||||

| GJD-450 | |||||

| GJD-500 | 300-500 | ||||

| GJD-600 | |||||

| GJD-750 | |||||

| GJD-1000 | 500-1000 | ||||

| GJD-1200 | |||||

| GJD-1500 | |||||

| GJD-1800 | |||||

| GJD-2000 | 1000-2000 | 2-20 | |||

| GJD-2500 | |||||

| GJD-3000 | |||||

| GJD-3500 | 2000-3000 | ||||

| GJD-4000 | |||||

| GJD-5000 | |||||

Gold and silver in the desorbed pregnant solution exist in the form of Au(CN)₂⁻ and Ag(CN)₂⁻ complex ions. During the electrolysis process, the gold and silver in ionic state gain electrons at the anode plate, are reduced to metallic gold and silver, and deposit (precipitate) on the surface of the cathode (carbon fiber or steel wool).

The complete set of equipment consists of three main modules: the reaction vessel, the heating system, and the gas circulation system.

Advantages

(1) Since solvent steam desorption and pregnant solution electrolysis are separated and operate independently without mutual interference, simultaneous solvent steam desorption and solvent recycling are achieved. No solvent steam enters the electrolysis process, ensuring the safety of the technology in application.

(2) The separation of desorption and electrolysis processes enables fully automated monitoring throughout, ensuring both operational safety and economic security in gold production.

(3) This control system ingeniously selects temperature and liquid level detection points and determines sensor installation methods, ensuring the sealing performance of the entire setup and eliminating potential safety hazards.

This control system features short electrolysis time, low tail solution grade, high safety and reliability, advanced automation, and excellent economic benefits, making it widely adopted in gold enterprises.