- output:0.5-100t/h

- Feed size:≤20mm

- Motor power:18.5-1000kw

Wet grinding ballmill is a mineral processing machine for milling the materials into powders after they are crushed.All the mineralore beneficiation and concentrating processes,including gravity separation, chemical,froth flotation,the working principle is to prepare fine size ores by grinding with ball mill which has.

| 规格型号 Model | 筒体转速 Rotational speed (r/min) | 最大装球量 Balls weight(t) |

给料粒度 Feeding size(mm) |

出料粒度 Output size(mm) |

产量 Capacity(t/h) |

电动机功率 Motor power(kw) |

机重 Weight(t) |

| φ900×1200 | 36 | 1 | ≤20 | 0.074-0.4 | 0.5-1.5 | 18.5 | 4 |

| φ900×1800 | 36 | 1.5 | ≤20 | 0.074-0.4 | 1.1-3.5 | 22 | 4.8 |

| φ1200×2400 | 31 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 30 | 9.5 |

| φ1200×4500 | 31 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 45 | 13.1 |

| φ1500×3000 | 33.8 | 7 | ≤25 | 0.074-0.4 | 2-6.3 | 75 | 16 |

| φ1500×4500 | 33.8 | 10 | ≤25 | 0.074-0.4 | 3-9 | 110 | 19 |

| φ1830×3000 | 23.8 | 10 | ≤25 | 0.074-0.4 | 4-11 | 130 | 25 |

| φ1830×3600 | 23.8 | 12 | ≤25 | 0.074-0.4 | 4.3-12 | 155 | 32 |

| φ1830×4500 | 25 | 15 | ≤25 | 0.074-0.4 | 4.5-16 | 155 | 33.7 |

| φ2100×3600 | 23.8 | 22.5 | ≤25 | 0.074-0.4 | 6-17 | 210 | 45.8 |

| φ2200×4500 | 23.7 | 28 | ≤25 | 0.074-0.4 | 9-25 | 280 | 46.5 |

| φ2400×4500 | 21 | 30 | ≤25 | 0.074-0.4 | 10-32 | 380 | 65 |

| φ2700×4500 | 20.7 | 43 | ≤25 | 0.074-0.4 | 15-40 | 480 | 97 |

| φ3200×4500 | 19 | 59 | ≤25 | 0.074-0.4 | 18-55 | 630 | 156.5 |

| φ3600×4500 | 17 | 75 | ≤25 | 0.074-0.4 | 30-100 | 1000 | 162 |

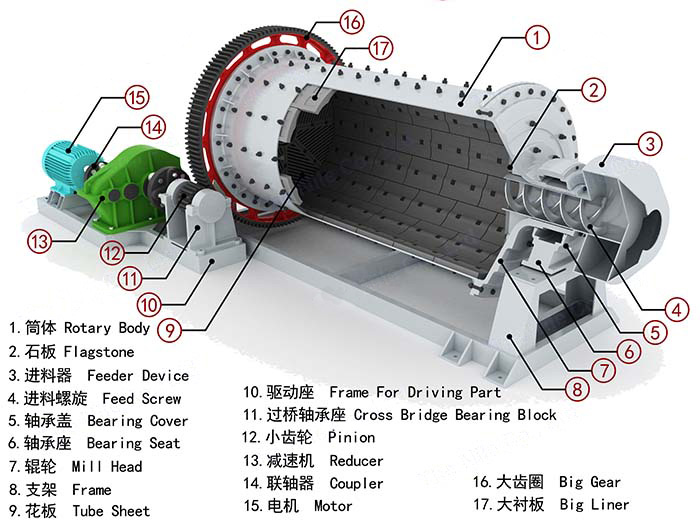

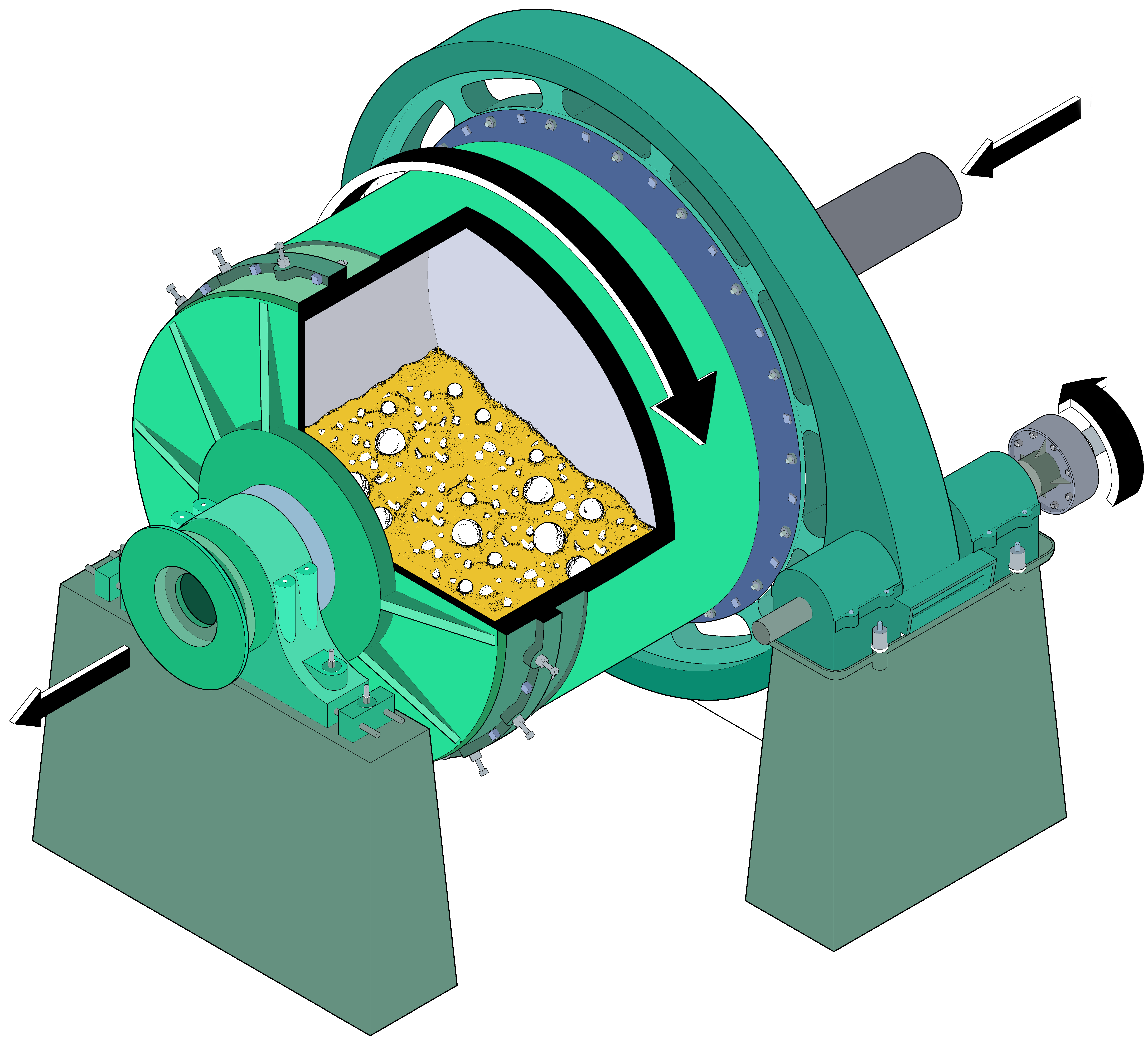

Ball Mill Motor drives the rotary cylinder through the rotation of reducer and surrounding large gear or it directly drives the cylinder with the rotation of surrounding large gear. The body of cylinder has installed appropriate grinding media - grinding mill balls or steel bars. They are raised to a certain height by centrifugal force and friction, and then fall down with the falling down or drain off state. Grinded materials are continuously given to the cylinder from the mouth, and then crushed by the movement of the grinding media. Finally, the materials will be discharged by the strength of overflow and continuous ore feeding so as to move to the next step.

Wet ball mill is mainly composed of the main motor, main reducer, transmission part, rotary part, main bearing, slow-speed transmission part, hoisting device, feed pipe, discharge pipe, outlet device, ring seal, base part, high and low pressure lubrication station, jet lubrication system, bearing cooling water system, etc. The hollow shaft is made of cast steel parts with replaceable liners, and the rotary large gear is manufactured by casting and gear hobbing. The cylinder is lined with wear-resistant liners, providing excellent abrasion resistance. The machine operates smoothly and reliably.

Wet ball mill is mainly composed of the main motor, main reducer, transmission part, rotary part, main bearing, slow-speed transmission part, hoisting device, feed pipe, discharge pipe, outlet device, ring seal, base part, high and low pressure lubrication station, jet lubrication system, bearing cooling water system, etc. The hollow shaft is made of cast steel parts with replaceable liners, and the rotary large gear is manufactured by casting and gear hobbing. The cylinder is lined with wear-resistant liners, providing excellent abrasion resistance. The machine operates smoothly and reliably.