- output:0.3-9.5t/h

- Feed size:15-30mm

- Motor power:7.5-75kw

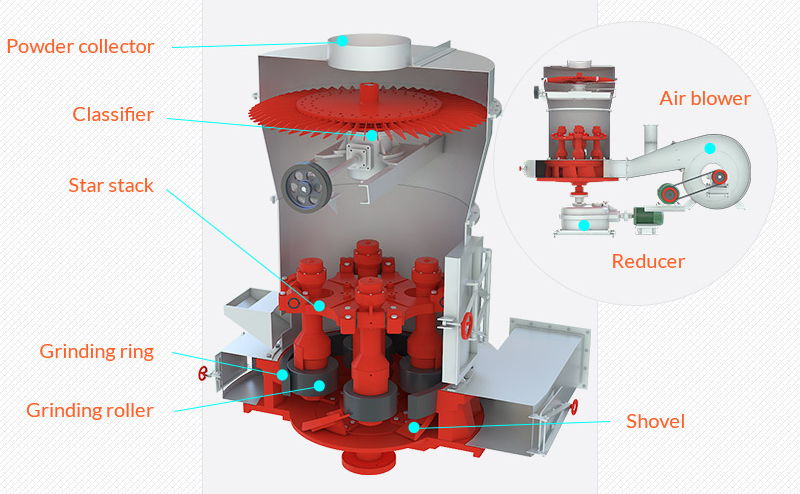

Raymond mill is a common grinding equipment.It is mainly be used for high fineness production of non- flammable and non-explosive minerals,chemicals,building materials with mohs hardness less than 7 Richter scales,humidity below 6%,the final product particle size can be adjustable between 40 and 400 meshes.The suitable minerals are barite,calcite,potash feldspar,limestone,talc,dolomite and gypsum,etc.

| 型号 Model | 磨辊个数Roller number(pcs) | 磨辊尺寸Roller size(mm) | 磨环内径和高度Inner diameter& height of ring(mm) | 最大进料尺寸 Max.feed size(mm) |

成品粒度Final size(mm) | 处理能力Capacity(t/h) | 主机功率 Power(kw) | 重量Weight(t) | 外形尺寸(mm) Overalldimension |

| 3R1510 | 3 | 150×100 | 570×100 | 15 | 0.2-0.044 | 0.3-1.2 | 7.5 | 2 | 3200×2100×3800 |

| 3R2115 | 3 | 210×150 | 630×150 | 15 | 0.2-0.044 | 0.4-1.6 | 15 | 3.6 | 4500×2800×5800 |

| 3R2615 | 3 | 260×150 | 780×150 | 20 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 | 5650×3305×3950 |

| 3R2715 | 3 | 270×150 | 830×150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 | 5600×3400×5900 |

| 3R3015 | 3 | 300×150 | 875×150 | 20 | 0.2-0.044 | 1.2-3.5 | 30 | 5.3 | 5700×3500×5900 |

| 4R3016 | 4 | 300×160 | 890×160 | 20 | 0.2-0.044 | 1.2-4 | 30 | 8.5 | 6500×4100×5200 |

| 4R3216 | 4 | 320×160 | 970×160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 | 9900×5800×10580 |

| 5R412 | 5 | 410×210 | 1280×210 | 30 | 0.2-0.044 | 3-9.5 | 75 | 24 | 7900×8000×9700 |

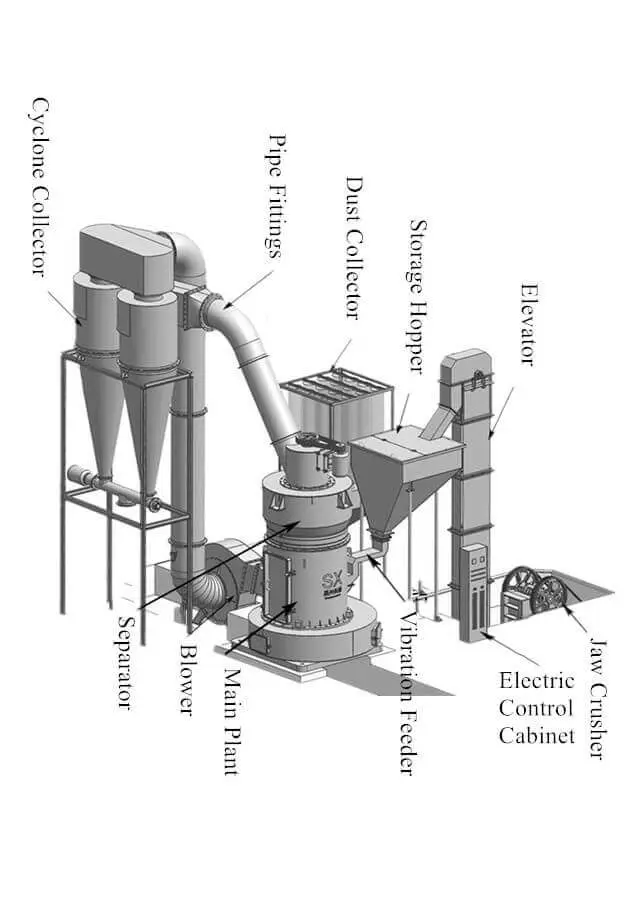

After the bulk material is crushed to the required particle size by the jaw crusher, the material is sent to the storage hopper by elevator, and then the material is continuously fed in evenly and quantitatively through the vibrating feeder Grinding in the main machine grinding chamber, the ground powder is taken away by the airflow of the fan, and classified by the analyzer. The fineness of the powder enters the large cyclone collector through the pipe with the airflow for separation and collection, and then the powder is discharged The valve discharge is the finished powder. The airflow is sucked into the blower by the return duct at the upper end of the large cyclone collector. The entire airflow system of this machine is closed and circulating, and it circulates under the condition of positive and negative pressure.

The main parts of a Raymond grinding mill plant are a cyclone collector, pipe fittings, dust collector, storage hopper, elevator, crusher, electric control cabinet, feeder, main plant, blower, separator, etc.

优势Advantages

The raymond grinding mill offers multiple advantages, including a long service life through its resilient coupling that minimizes vibration and noise, along with a simple yet compact system design that allows for space-saving outdoor arrangements to significantly reduce investment costs. It features high-performance sealing technology, an eco-friendly air circulation system paired with an advanced dust remover for environmental compliance, and energy-efficient operation. Additionally, its convenient impeller adjusting devices enhance the precision of finished products, ensuring optimal performance and quality.

✔ Efficient grinding and particle size adjustment: The high-pressure spring system is used to enhance the grinding roller pressure (800-1200kg), and the closed-circuit air selection cycle is used to achieve 80-425 mesh particle size adjustment, and some models can reach more than 1000 mesh.

✔ Stable operation and low noise: The whole machine adopts a three-point positioning structure to reduce vibration, the noise is as low as 60 decibels, and the operation stability is high.

✔ Strong adaptability: It is suitable for non-flammable and explosive materials with a humidity of less than 6% and a Mohs hardness of no more than 9.3, and can directly process raw materials below 20 mm.