- output:1-10t/h

- Feed size:<35mm

- Motor power:18.5-132kw

High-pressure roller mills used in the mineral industry,building industry,chemical industry and metallurgy industry.It is used for high fineness production of more than 400 kinds of non flammable and non-explosive materials of Mohs hardness less than 7 Richter scales,humidity below 6%,such as quartzite,feldspar,barite,fluorite,dolomite,garnet,carborundum,bauxite,zircon sand,marble,calcite,iron ore,phosphate ore,coal briquette,ceramic,slags,etc.The final product particle size can be adjustable between 40 and 800 meshes.

| 产品型号 Model | 磨辊Roller | 磨环Ring | 最大进料粒度 Max.feed size(mm) |

成品粒度Final size(mm) | 主机功率 Power(kw) | 处理能力 Capacity(t/h) | |||

| 个数(pcs) Quantity | 直径(mm) Diameter |

高度(mm) Height | 内径(mm) Diameter |

高度(mm) Height |

|||||

| YGM-75 | 3 | 260 | 150 | 780 | 150 | <15 | 0.613-0.019 | 18.5 | 1-3 |

| YGM-85 | 3 | 270 | 150 | 830 | 140 | <20 | 0.613-0.019 | 22 | 1.2-4 |

| YGM-95 | 4 | 310 | 170 | 950 | 170 | <25 | 0.613-0.019 | 37 | 2.1-6.5 |

| YGM-130 | 5 | 410 | 210 | 1280 | 210 | <30 | 0.613-0.019 | 75 | 5-10 |

| YGM-160 | 6 | 440 | 270 | 1480 | 270 | <35 | 0.613-0.019 | 132 | 8-10 |

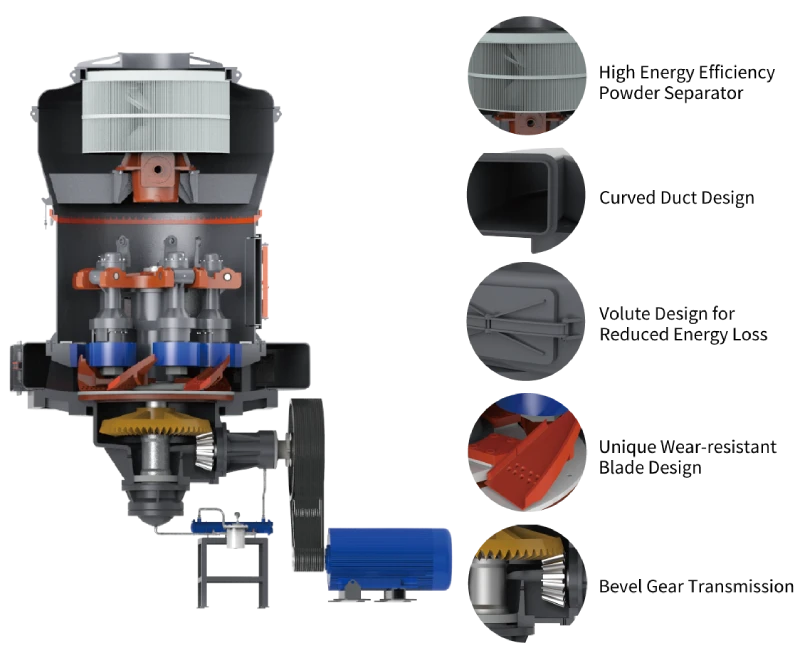

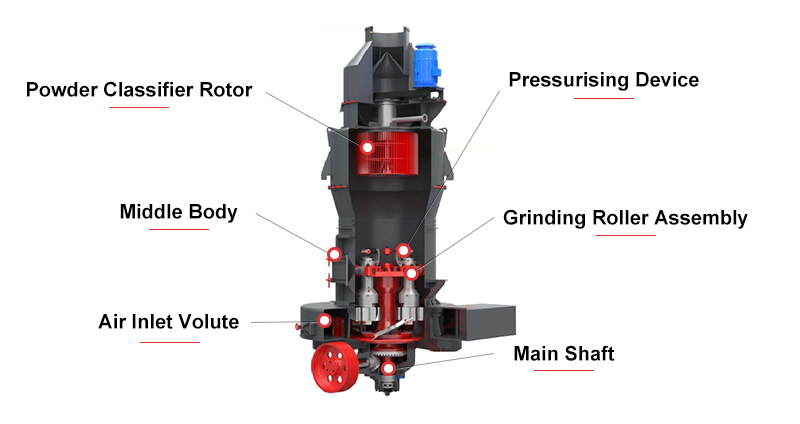

The working principle of the high pressure grinding mill is similar to that of the traditional Raymond mill, but the grinding device is equipped with a high pressure spring with a pressure of 1000-1500kg. When the machine is working, the grinding roller of the high-pressure roller mill rotates around the main shaft, and rolls close to the grinding ring under the action of the high-pressure spring and centrifugal force, and its rolling pressure is 1.2 times higher than that of the Raymond pulverizer under the same power conditions, so The output of the high pressure pulverizer is greatly improved.

When the material to be ground enters the grinding chamber, it is scooped up by the shovel and sent to the grinding roller and the grinding ring for rolling. The crushed powder is brought into the analyzer with the circulating air of the blower. Qualified fine powder enters the cyclone powder collector with the airflow. Larger particles fall back into the grinding chamber for regrinding. The circulating air returns to the blower to repeat the above process, and the remaining air enters the bag filter for purification. After the grinding roller and the grinding ring reach a certain level of wear, adjust the length of the high pressure spring to maintain a constant grinding pressure between the grinding roller and the grinding ring. So as to ensure stable output and fineness.

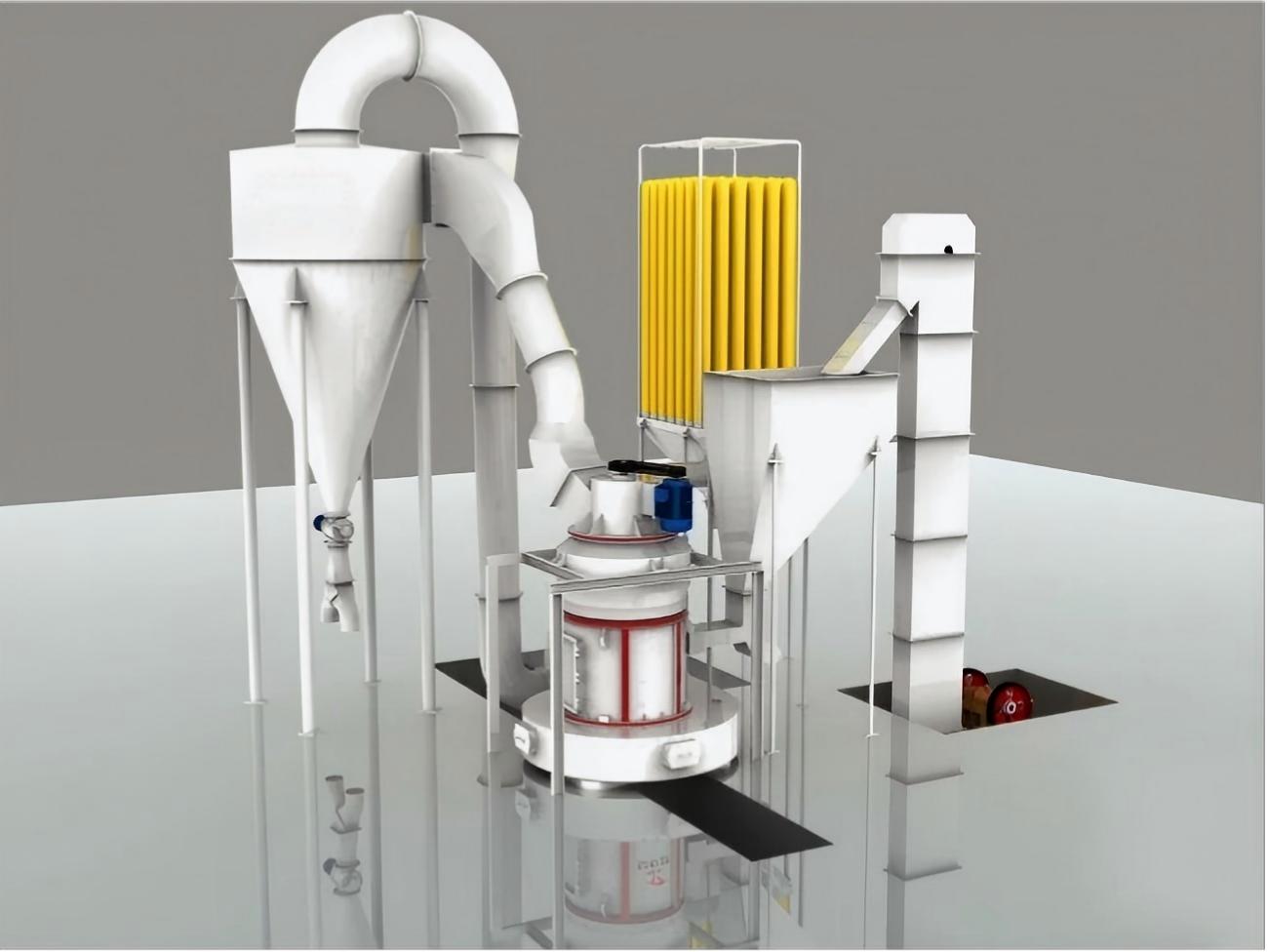

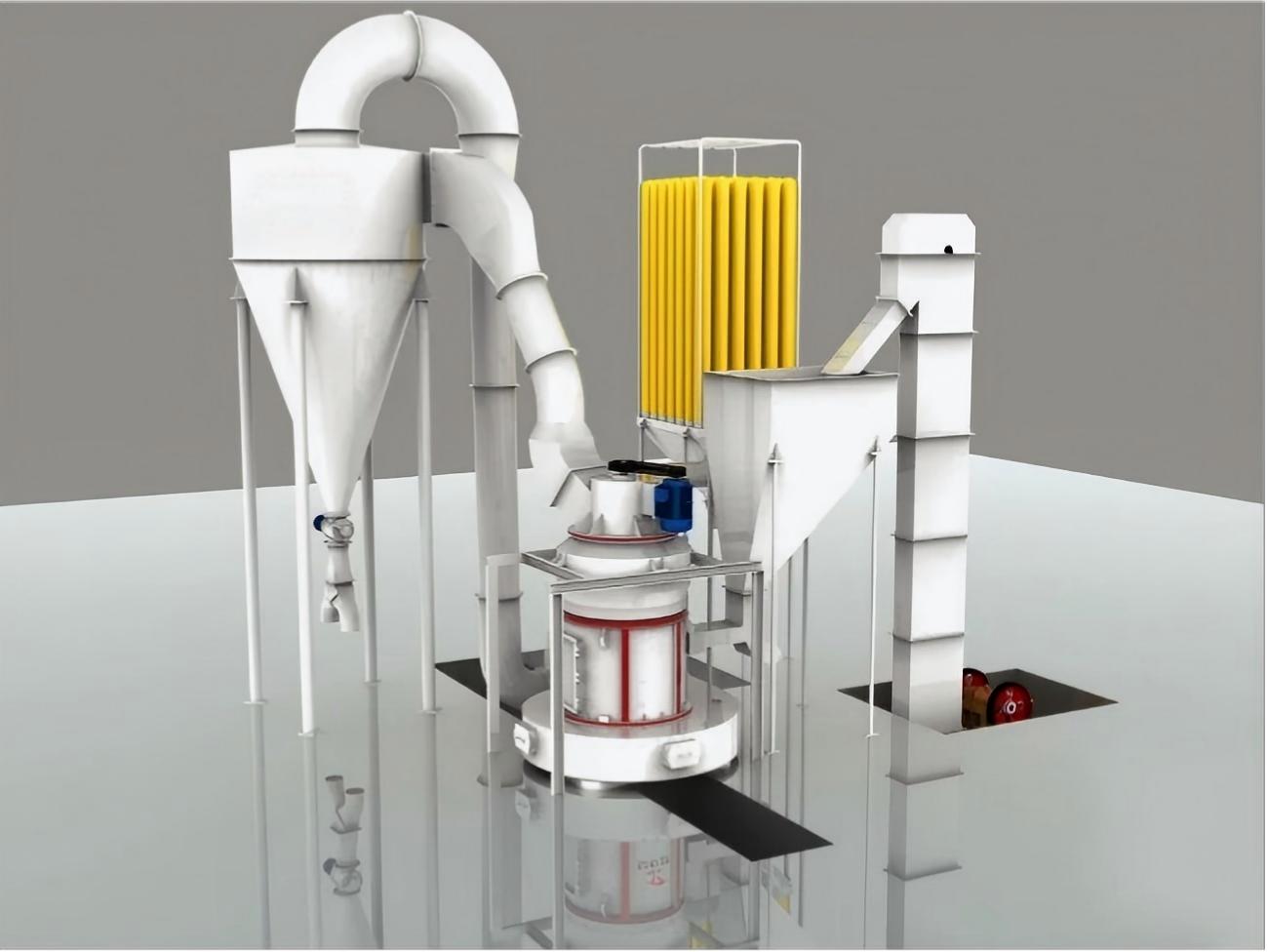

The complete set of high pressure micro-powder grinding equipment is mainly composed of grinding system, analysis system, dust removal system and high-pressure device. The components of the grinding system include motors, blades, grinding rollers, gearboxes and other accessories. Compared with other grinding mills, the structure of the high pressure micro-powder mill has the advantages of higher efficiency and more wear resistance.

优势Advantages

1. The grinding force is large. The grinding roller assembly of the high-pressure grinding mill adopts a high-pressure spring device to increase the grinding force. The grinding force of each grinding roller assembly can be increased by 500Kg on the original basis, which greatly improves the milling efficiency.

2. The grinding area is large, and the grinding height of the grinding roller and grinding ring is increased from 160mm to 200mm.

3. Large amount of shovel.

4. High classification accuracy.

5. Double cyclone collector.

6. The main engine adopts a buffer device, and the structure of the main casing is optimized to ensure stable operation and low noise.

7. The main engine and analysis machine adopt quick-change pressing device, which is convenient for maintenance.

8. The residual wind is collected by cloth bags, and there is no dust pollution.

9. The blower of the high pressure grinding mill adopts a high-pressure centrifugal fan, and the air volume and air pressure are increased, which greatly improves the pneumatic conveying capacity