- output:8000-600kg

- Feed size:≤10mm

- Motor power:/

Ultrafine powder grinding mill is a machine for producing fineness and ultra-powder It mainly is suitable for, the low degree of hardness,the Mohs's cale is not bigger than 7 levels non-flammable explosive britle material,like calcite,chalk,limestone,dolomite,kleit,bentonite,talc,mica,magnesite,ilite,leaf agalmatolite,vermiculite,sepiolite,concave-convex good stone,rectorite,diatomaceous earth,barite,gypsum,alunite,graphite,fuorspar,rock phosphate,potassium ore,pumice and so on 100 many kinds of materials.

| 名称Name | Unit | HGM80 | HGM100 | HGM125 |

| Number of roller | PC | 21 | 27 | 40-44 |

| Roll table ring | Layer | 3 | 3 | 4 |

| Averageworking diameter | mm | 800 | 1035 | 1300 |

| Feed granularity | mm | ≤10 | ≤10 | ≤10 |

| Fineness of finished product | μm/order | 47-5/325-2500 | 47-5/325-2500 | 47-5/325-2500 |

| Capacity | kg | 4000-600 | 6000-900 | 8000-1200 |

| Dimension(length xwidth xheight) | m | 11.9×2.7x5.8 | 14.5×3.8x6.3 | 14×9×10.25 |

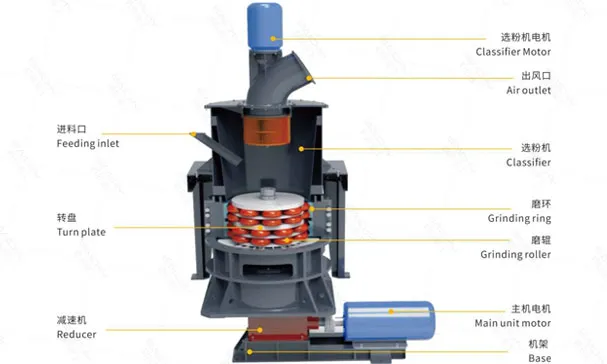

The ring mill operates on the principle of compression and grinding.

It consists of 3 or 4 grinding rings and several grinding rollers.

The material is fed into the center of the rotating grinding ring.

As the ring turns, centrifugal force pulls the material to the edge of the ring.

At the edge, the material is ground between the ring and the rollers.

Grinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grinding. It rotates and provides the surface against which the rollers press the material.

Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ring. They roll on the ring and crush the material into fine particles.

Classifier: A classifier is used to separate fine particles from coarse ones. The fine particles are collected, while the coarse ones are sent back for further grinding.

Feeder: The feeder uniformly feeds the material into the grinding chamber.

Blower: The blower provides airflow to transport the ground material through the mill and to the classifier.

Cyclone Separator: This separates the ground particles from the air stream and collects them.

优势Advantages

High Fineness: Ring mills are capable of producing very fine particles, making them suitable for ultrafine grinding applications.

Efficiency: The design of the ring mill allows for efficient grinding with lower energy consumption compared to other grinding methods.

Consistency: Provides uniform particle size distribution.

Compact Design: The vertical structure of the ring mill requires less space compared to horizontal mills.