- output:3-15t

- Feed size:/

- Motor power:96-280kw

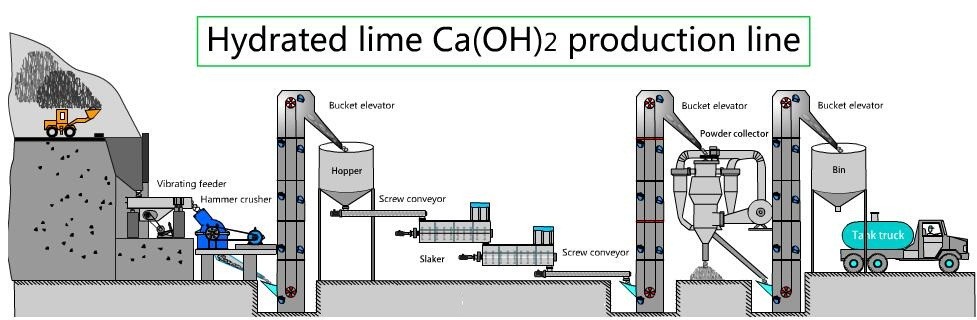

Hydrated lime fully automatic production line is designed and successful applied by the research and development department of Nile Machinery Be equipped with crushing,conveying ,digestion,slag,dust powder,electronic control 7 systems With high production efficiency ,low comprehensive energy consumption ,high level of automatic and control,with the characteristics of environmental friendly,which has been the first choice for the hydrated lime production.

| 型号Model | 用水量Water supply volume(t/h) | 功率 Power(kw) |

消石灰指标Hydrated lime index |

| 3-4t | 300kg/T Lime | 96 | 100-600 mesh(Adjustable) 100-600 mesh (can be adjusted) Water content≤1% Impurity content ≤3% |

| 5-6t | 300kg/T Lime | 120 | 100-600 mesh(Adjustable) 100-600 mesh (can be adjusted) Water content≤1% Impurity content ≤3% |

| 6-8t | 300kg/T Lime | 145 | 100-600 mesh(Adjustable) 100-600 mesh (can be adjusted) Water content≤1% Impurity content ≤3% |

| 8-10t | 300kg/T Lime | 195 | 100-600 mesh(Adjustable) 100-600 mesh (can be adjusted) Water content≤1% Impurity content ≤3% |

| 12-15t | 300kg/T Lime | 280 | 100-600 mesh(Adjustable) 100-600 mesh (can be adjusted) Water content≤1% Impurity content ≤3% |

The complete equipment for hydrated production line from our company adopts PLC control system, which performs the data processing, parameter setting, direct digital display, automatic alarm function and etc, increasing the production efficiency. World-class electric elements are used to ensure the operation safety and control system stability of the whole production line.

The complete equipment is divided into 9 systems:

① Crushing system: hammer crusher.

② Conveying system: bucket elevator and belt conveyor.

③ Slaking system: qualified CaOH is put into the first slaking device to be primarily slaked, then it proceeds to the second or third slaking device to be further and totally slaked or resolved, and then, qualified primary CaOH products come into being and the slaking rate is 98%.

④ Residue discharging system: in the first level discharging process, residue with +0.5cm size in the semi-finished products are being discharged; in the second level discharging process, sand and coal dust with -0.5cm size are being discharged.

⑤ Dust collecting system: this system collects the dust produced in the production, and the dust collecting rate meets the national standard (20mg/m3), therefore, secondary pollution can be avoided.

⑥ Powder collecting system: powder is collected by closed circulating air.

⑦ Electric control system: PLC control system and CRT screen display; the PLC system performs the data processing, parameter setting, direct digital display, automatic alarm function and etc. World-class electric elements are used to ensure the operation safety and control system stability of the whole production line.

⑧ Packing system: non-weighing packing is included.

⑨ Proportioning system: digital display; water and lime proportion is adjusted manually.