- output:3-50t/h

- Feed size:<50

- Motor power:118-686kw

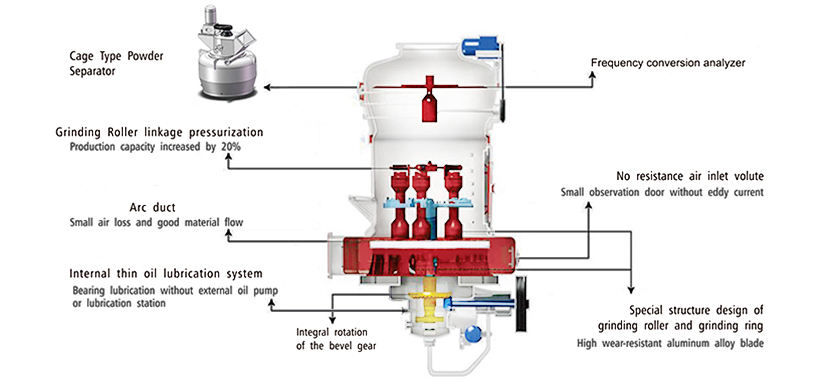

The MTW series Euro-type trapezium mill is a high-efficiency mining machine with innovative structural designs, such as bevel gear transmission and an internal thin oil lubrication system. It offers large output capacity (up to 60tph), low energy consumption, and advanced classification technology for accurate fineness adjustment. With a curved air duct design, annular water cooling, and extended oil change cycles (4 months), it ensures prolonged equipment life and reduced maintenance costs. Ideal for limestone, gypsum, and other non-metallic mineral grinding in industries like construction and metallurgy.

| M o d e l | MTW110 | MTW138 | MTW175 | MTW215 |

| Roller major diameterxheight(mm) | φ360×190 | φ460×240 | φ520×280 | φ640×320 |

| Roller inner diameterxheight(mm) | φ1100×190 | φ1380×240 | φ1750×280 | φ2150×320 |

| Max.feed size(mm) | <30 | <35 | <40 | <50 |

| Fineness of finished products(mm) | 1.2-0.045最细可达0.038 Finest up to 0.038 | 1.2-0.045最细可达0.038 Finest up to 0.038 | 1.2-0.045最细可达0.038 Finest up to 0.038 | 1.2-0.05最细可达0.038 Finest up to 0.038 |

| Capacity (t/h) | 3-10 | 6-20 | 10-35 | 20-50 |

| Main motor Power (kw) | 55 | 90 | 160 | 280 |

| Blower motor Power (kw) | 55 | 110 | 200 | 315 |

| Classifier motor Power(kw) | 7.5 | 22 | 37 | 90 |

| Electro-vibrating feeder | Model-GZ2F | Model-GZ3F | Model-GZ4F | Model-GZ5F |

| Power (kw) | 0.15 | 0.2 | 0.45 | 0.65 |

In main unit's working process, grinding roller device not only performs gyration by surrounding the central axis,but also performs revolution by surrounding the grinding ring. The grinding roller itself self- rotates by rubbing effect, the merit of which is that it can not only fully pulverize material, but also ensure uniform wear around grinding roller, increasing service life of grinding roller. perching knife, which is installed under grinding roller hanger, rotates with grinding roller at the same time. In this process, the perching knife throws up materials and feed them into grinding ring of grinding roller to form a padding layer. This padding layer is pulverized through outward centrifugal force generated by grinding roller(namely extrusion force between grinding roller and grinding ring)for the purpose of pulverization.

The system consists of grinding mill, separator, air blower, jaw crusher, vibrating feeder, hopper, dust collector, pipe, powder collector, electric cabinet, motors, etc.