- output:0.22-8t

- Feed size:/

- Motor power:5.5-90kw

The batch ball mill s a small non-continuous production mill.With advantages simple structure,easy operation,less auxiliary equipment,it can once obtain high fineness products.It can adopt dry-milling with special product collection hopper and wet milling with slurry discharge valve.The batch ballmill is applied to the production lines with high fineness requirements or small production lines with special materials.

| 型号 Model | 有效容积(m³) Effective volume | 物料单次最大装填量(t) Max material loading per batch | 筒体转速Rotational speed(r/min) | 电机功率Motor power(kw) | 重量Weight(t) |

| TCQ910×1120 | 0.68 | 0.22 | 36 | 5.5-11 | 3 |

| TCQ1200×1400 | 1.5 | 0.5 | 32 | 11-18.5 | 3.8 |

| TCQ1500×1800 | 3 | 1 | 28 | 15-22 | 4.5 |

| TCQ1800×2100 | 5 | 1.65 | 26 | 18.5-30 | 5.5 |

| TCQ2100×2100 | 6.8 | 2.2 | 22 | 22-37 | 7.4 |

| TCQ2200×2400 | 8.5 | 2.8 | 20 | 30-45 | 8.2 |

| TCQ2500×2900 | 13.2 | 4.4 | 16 | 37-55 | 9.3 |

| TCQ2800×3700 | 21.2 | 7 | 14.5 | 55-75 | 12.5 |

| TCQ3000×3700 | 24.3 | 8 | 14 | 75-90 | 18.6 |

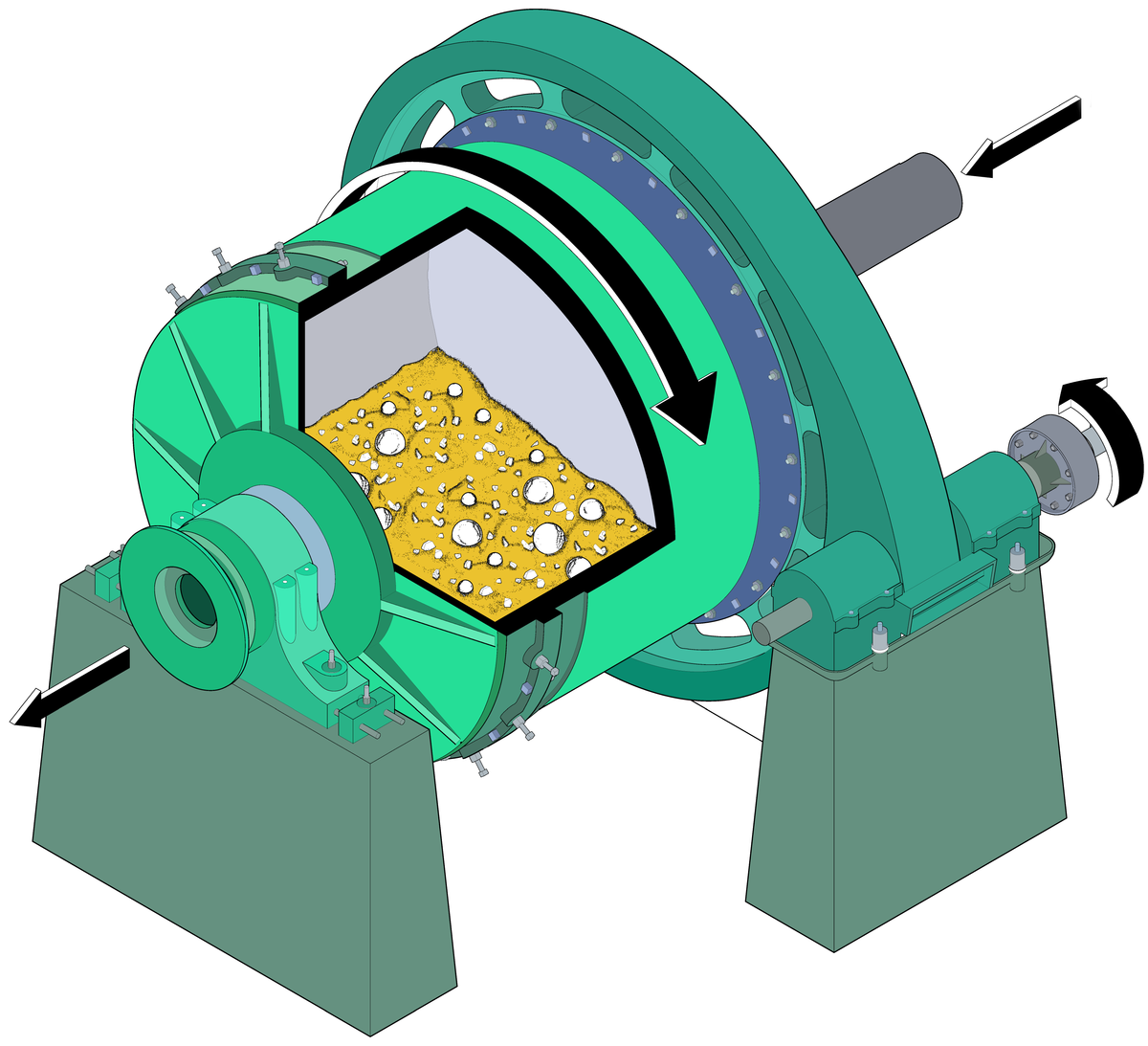

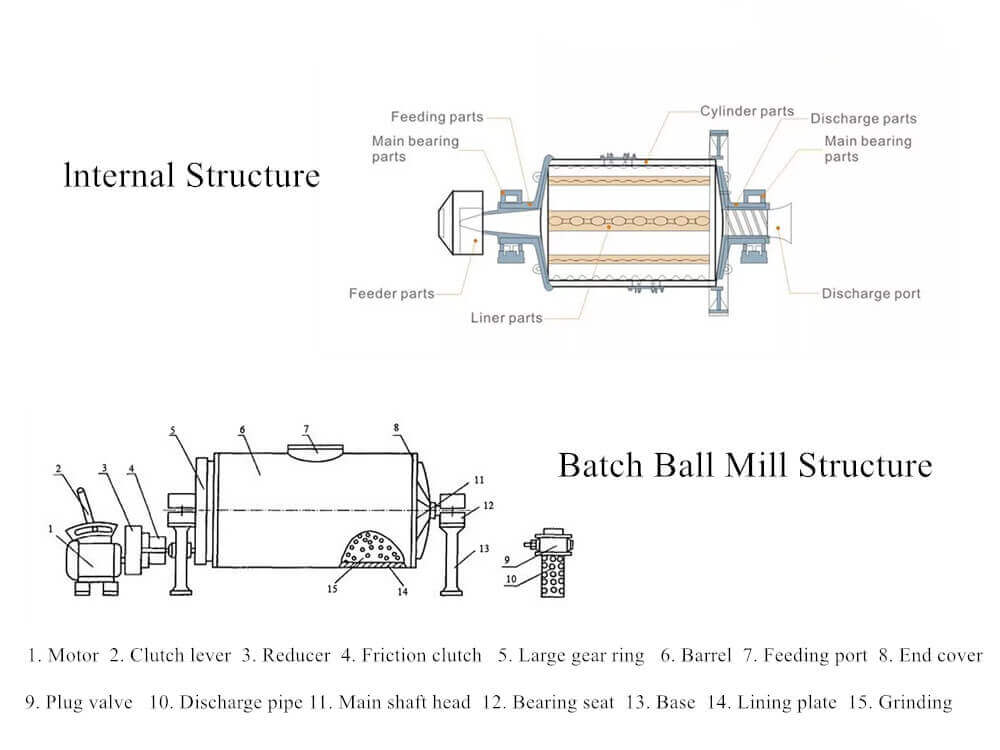

The batch ball mill is of horizontal, cylindrical, and tubular structure. It comes with two cabins and is a grate ball mill. The materials are evenly fed through the charging device to the first warehouse where there are step scales boards, corrugated scale boards, and different specifications of steel balls. When the cylinder rotates, the centrifugal force produced causes the steel balls to impact and grind the materials in the ball mill. The materials are then lead to the second cabin for further milling until they turn into powders and are discharged from the outlet.

The batch ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, pinion, motor, electric control), and other main parts. The hollow shaft is made of steel casting with a removable lining. The rotary gear is processed by casting hobbing. The cylinder is embedded with a wear-resistant lining plate, which has good wear resistance. The batch mill runs smoothly and works reliably.

优势Advantages

Control of the final product particle size through grinding time

Flexibility of use

Easy transition from one grinding process to another

Possibility of heating or cooling the drum

Easy installation and maintenance

Long service life of grinding balls

Adaptability of the quality of balls and drum lining

Grinding in wet or dry conditions