- output:1.4-87t/h

- Feed size:≤25mm

- Motor power:45-3550kw

Dry grinding ball il is charactenized by high grinding efficiency,single large capacity,low power consumption and small dust pollution.It generally uses the mulichambers.It is commonly used in closed-circuit miling and open flow milling in the field of cement,fly ash,a variety of non-metallic materials dry miling production.

| 规格型号 Model | 有效容积(m³) Effective volume | 装球量 Balls weight(t) |

给 料 粒 度 ( m m ) Feeding size | 产量(t/h) Capacity | 主减速机Main reducer | 配用电机功率 Motor power(kw) | 机重Weight(t) |

| φ1200×4500 | 4.7 | 6.5 | ≤25 | 1.4-2 | ZD 30 | 45 | 13.1 |

| φ1500×5700 | 9.4 | 13 | ≤25 | 3.5-4.5 | ZD 40 | 130 | 24 |

| φ1830×6400 | 15.7 | 22 | ≤25 | 5.5-6.5 | ZD 60 | 210 | 38 |

| φ1830×7000 | 17.1 | 23.5 | ≤25 | 6-7 | ZD 60 | 210 | 43 |

| φ2200×6500 | 23 | 31.5 | ≤25 | 8-10 | ZD 70 | 380 | 50.2 |

| φ2200×7500 | 26.5 | 36 | ≤25 | 10-11 | ZD 70 | 380 | 53.2 |

| φ2200×8000 | 28.3 | 39 | ≤25 | 10-12 | ZD 70 | 380 | 55 |

| φ2400×11000 | 46.3 | 64 | ≤25 | 19-21 | ZD 80 | 680 | 99.2 |

| φ2400×13000 | 54.7 | 75.5 | ≤25 | 21-23 | MBY710 | 800 | 115.2 |

| φ2600×13000 | 88.6 | 122 | ≤25 | 28-32 | MBY800 | 1000 | 148 |

| φ3000×12000 | 78.9 | 109 | ≤25 | 32-35 | MBY900 | 1250 | 168.6 |

| φ3000×13000 | 85.5 | 118 | ≤25 | 34-37 | MBY900 | 1400 | 172.3 |

| φ3200×13000 | 134.2 | 185 | ≤25 | 45-50 | MBY1000 | 1600 | 218 |

| φ3800×13000 | 137.1 | 189 | ≤25 | 60-62 | MFYX250 | 2500 | 286 |

| φ4200×13000 | 167.5 | 231 | ≤25 | 85-87 | MFX355 | 3550 | 320 |

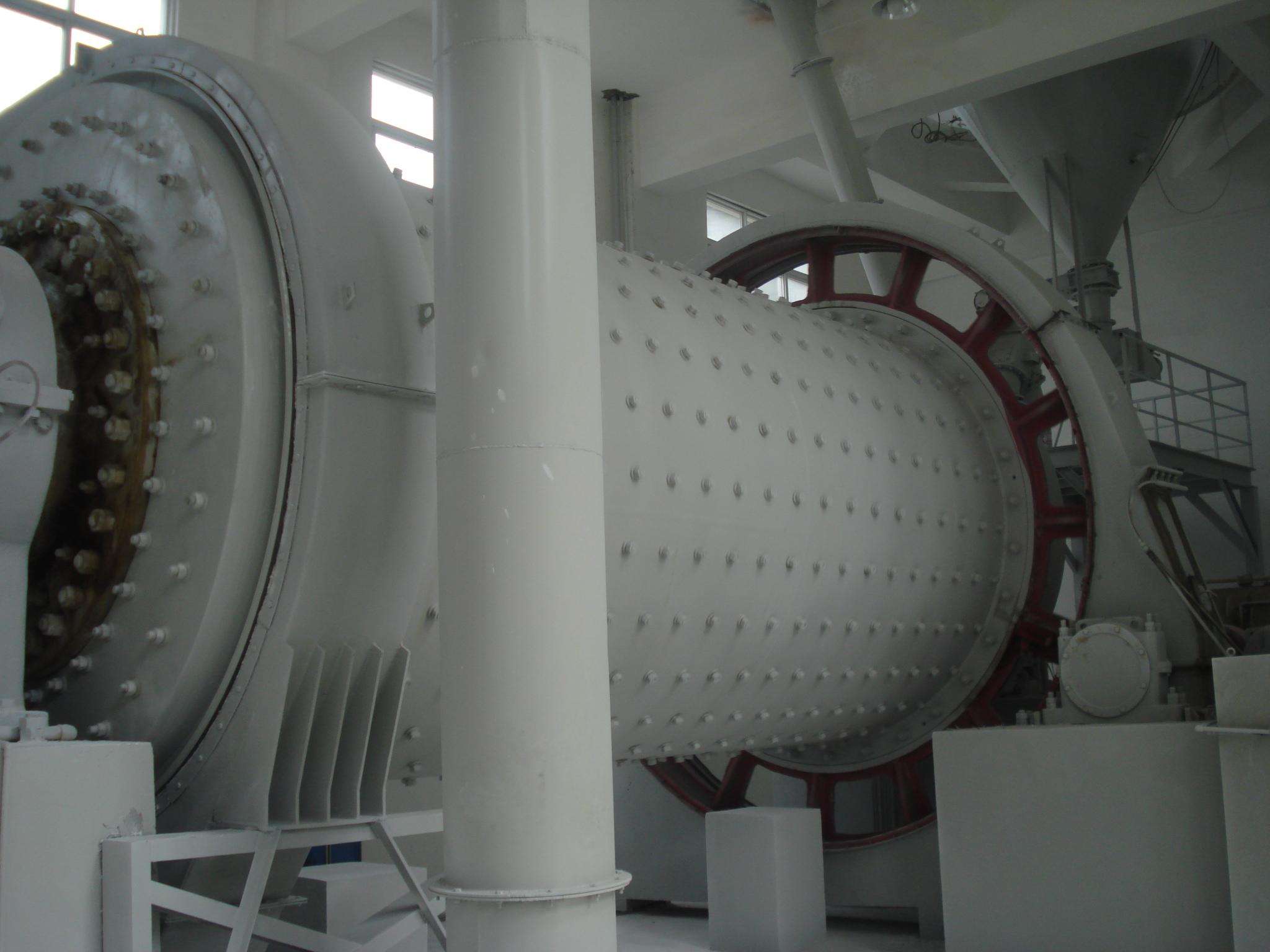

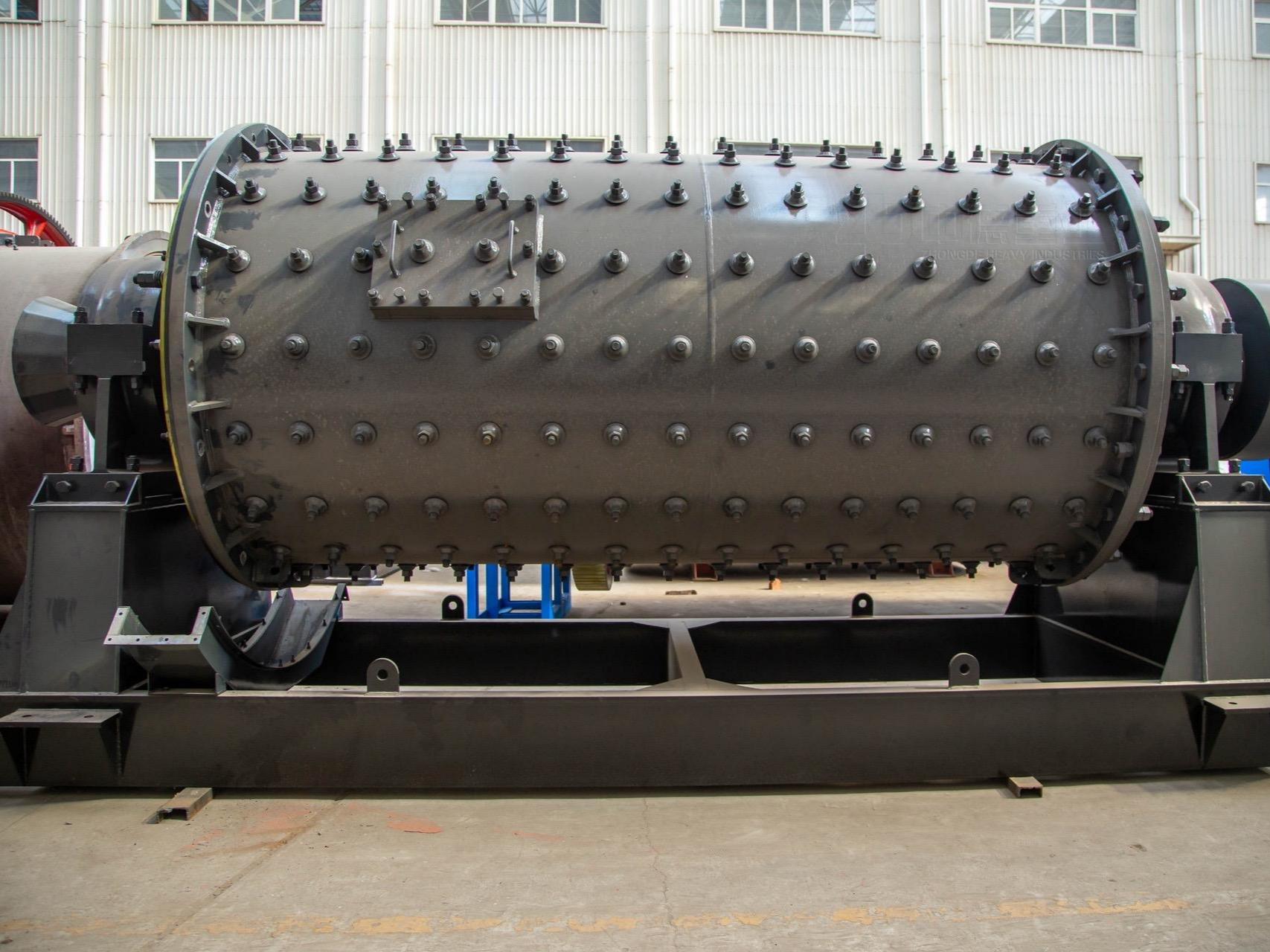

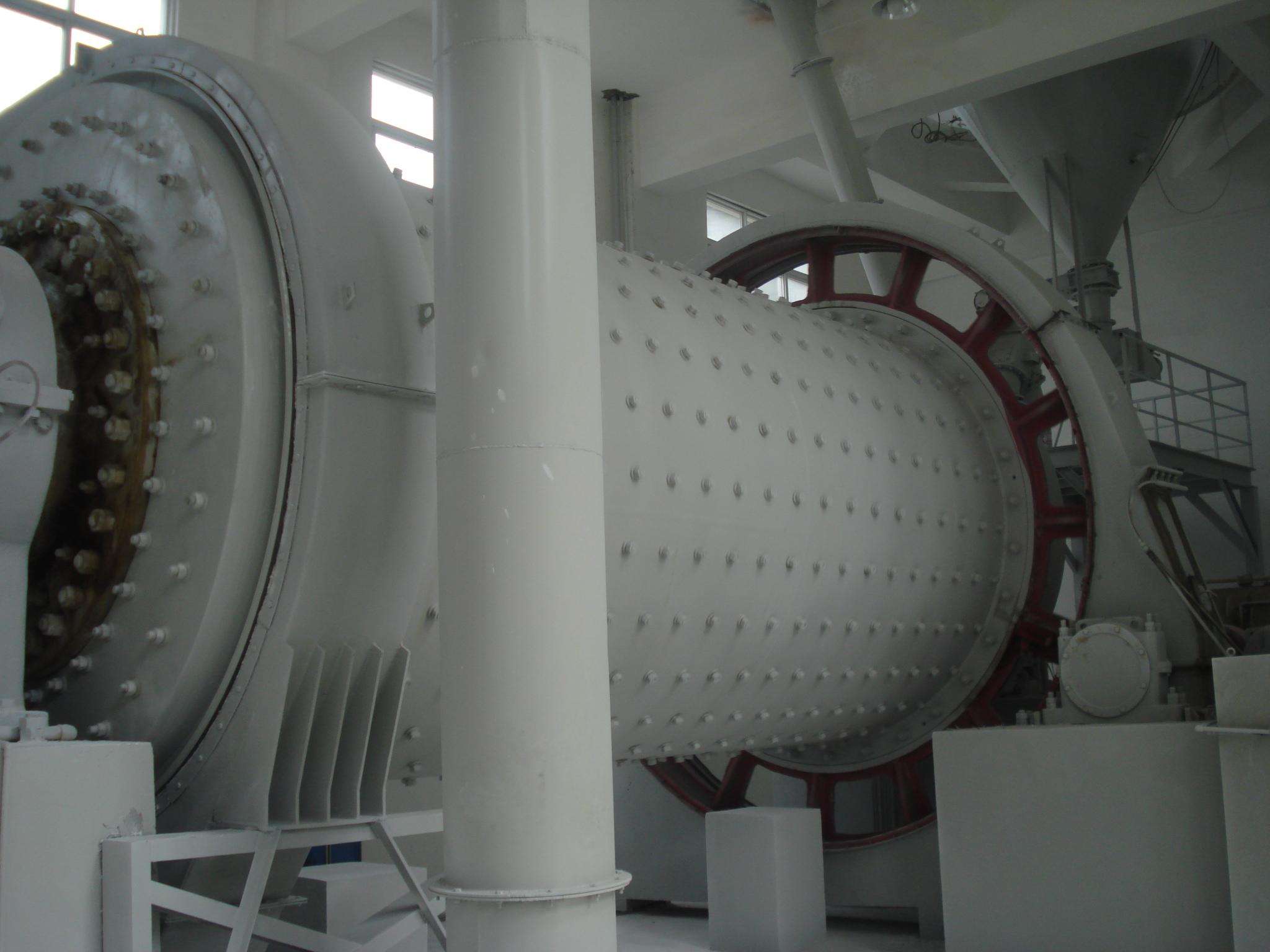

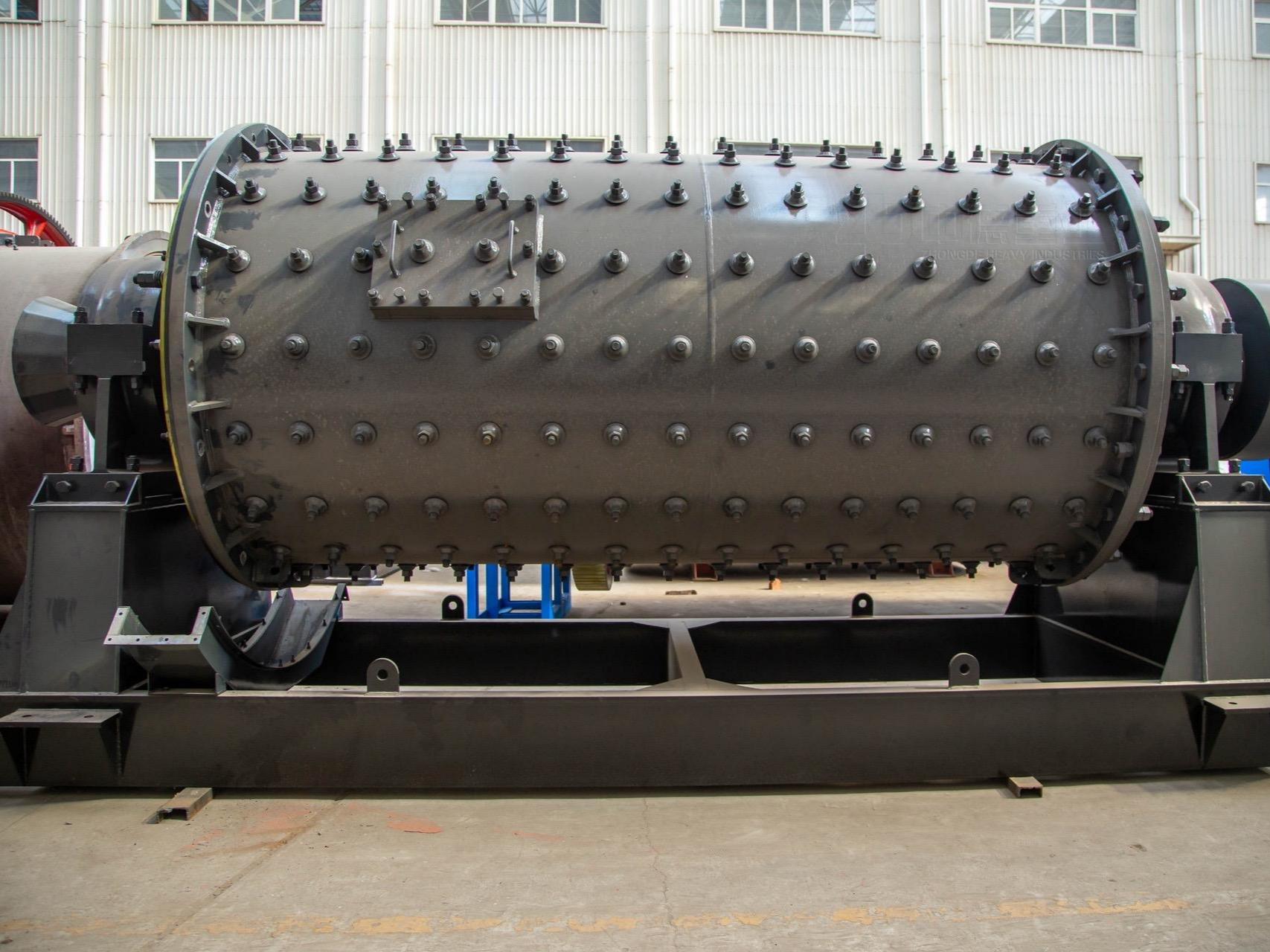

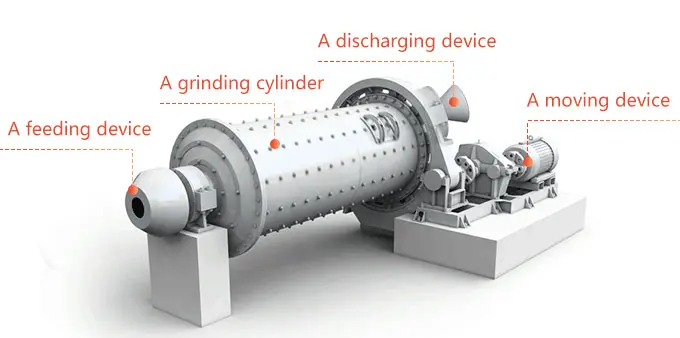

The ball mill is a horizontal rotating device transmitted by the outer gear. The materials are transferred to the grinding chamber through the quill shaft uniformly. There are ladder liner and ripple liner and different specifications of steel balls in the chamber. The centrifugal force caused by rotation of barrel brings the steel balls to a certain height and impact and grind the materials. The ground materials are discharged through the discharging board thus the grinding process is finished.

The machine is composed of feeding part, discharging part, turning part and driving part (reducer, small driving gear, electric motor and electric control). The quill shaft adopts cast steel part and the liner is detachable. The turning gearwheel adopts casting hobbing process and the drum is equipped with wear-resistant liner, which has good wear-resistance. The machine is with stable and reliable working condition. Moreover, according to different materials and discharging methods, there are dry ball mills and wet ball mills for choice.

优势Advantages

Enhanced Lining Plate Durability: The lining plate, subjected to an advanced double-medium quenching process, exhibits exceptional wear and impact resistance. It maintains its shape under heavy production loads, minimizing deformation and wear.

Versatile Lining Plate Performance: Compared to traditional high manganese steel liners, our medium alloy, double-medium quenched lining plates offer superior cost-effectiveness. They excel in both wet and dry grinding conditions, handling various ores and rocks efficiently.

Increased Gear Strength: The use of displacement gears significantly enhances gear bending strength, eliminating undercutting issues common in traditional designs.

Improved Bearing Lifespan: By enlarging the hollow shaft diameter, we’ve increased the radial clearance between the bearing and the feed/discharge screw cylinder. This improved heat dissipation prolongs bearing life.

Energy Efficiency and Reduced Wear: Our thin oil lubrication system replaces traditional grease lubrication, reducing friction and wear on bearings and other components. This results in lower energy consumption and extended equipment life.