- output:

- Feed size:

- Motor power:

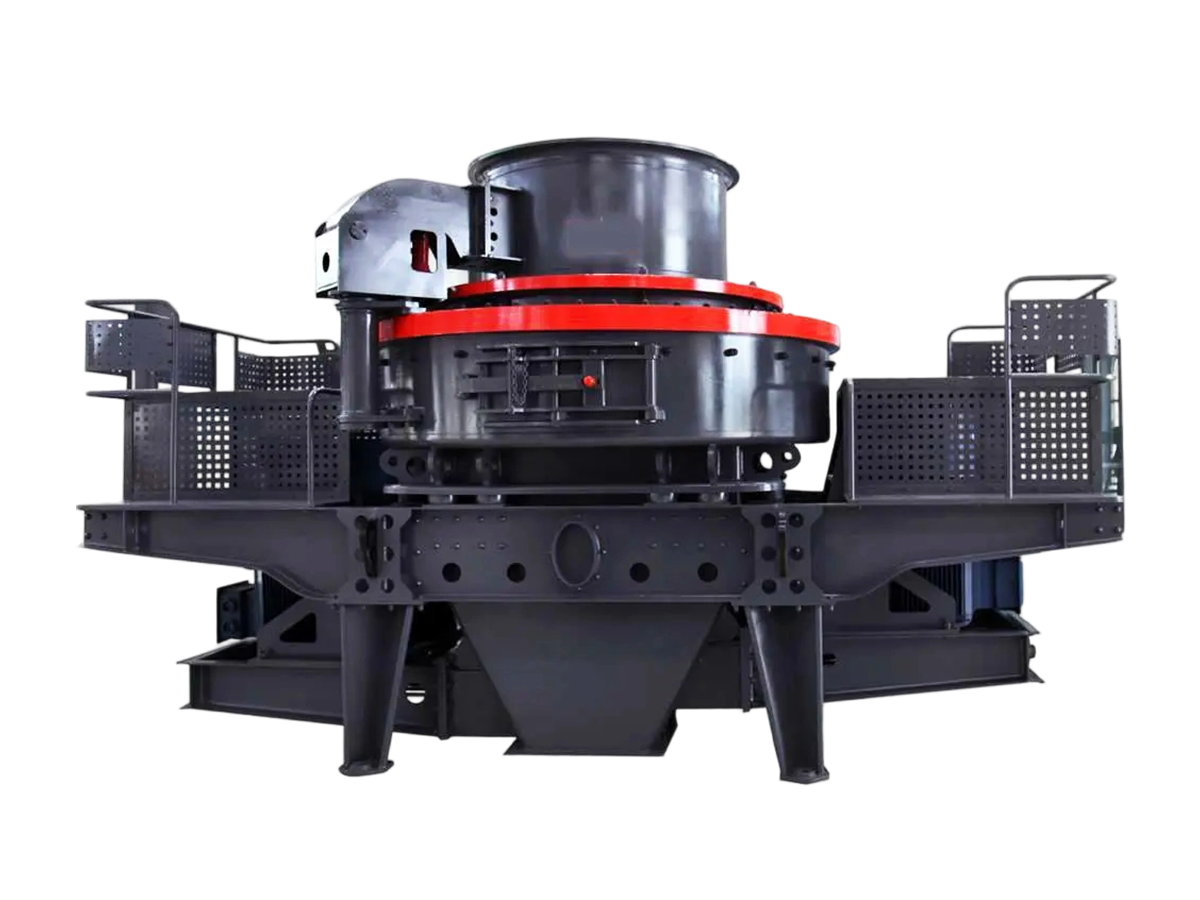

VSl-sand making machine is widely used for fine crushing and coarse grinding of metal and non metal ores, cement,refractory material,grinding material,glass raw material,building aggregates,artificial sand and all kinds of metallurgical slags.It is especially suitable for medium hardness materials;high hardness materials and corrosion resistance materials,such as carborundum,emery,sintered bauxite,magnesia,etc.

| 规 格 型 号 M ode l | VS17611 | VS18518 | VS19526 | VS1140 | VSI1145 | |

| 生产能力Capacity(t/h) | 瀑落与中心进料 Central feeding with circular cascade feeding |

120-180 | 200-260 | 300-380 | 450-520 | 500-640 |

| 全中心进料Fully central feeding | 60-90 | 100-130 | 150-190 | 225-260 | 250-360 | |

| 最大入料尺寸Max.feedingsize(mm) | 软料Soft material | <35 | <40 | <45 | <50 | <50 |

| 硬料Hard material | <30 | <35 | <40 | <45 | <45 | |

| 转速Rotation speed(r/min) | 1700-1890 | 1520-1690 | 1360-1510 | 1180-1310 | 1100-1310 | |

| 电动机型号Model of motor | Y250M-4 | Y280M-4 | Y315M-4 | Y315L2-4 | Y315L2-4 | |

| 双电机功率Double motor powerkw) | 2×55 | 2×90 | 2×132 | 2×200 | 2×220 | |

| 最大外形尺寸Overall dimension 长×宽×高L×W×H(mm) | 3600×2248×2533 | 4378×2350×2667 | 4640×2650×2800 | 5570×2900×3000 | 5100×2790×3320 | |

| 重量Weight(t) | 10 | 12 | 16 | 25.6 | 27.5 | |

VSI sand making machine adopts the working principle of ” Stone on stone ” and “stone on iron”. “Stone on stone” is suitable for materials with high corrosiveness above medium hardness, and is suitable for material shaping. “Stone on iron” is suitable for medium-hard and less corrosive stones, and can be crushed, processed and made sand with large output. This working principle makes the VSI sand crusher more efficient in sand production and adapts to more materials.

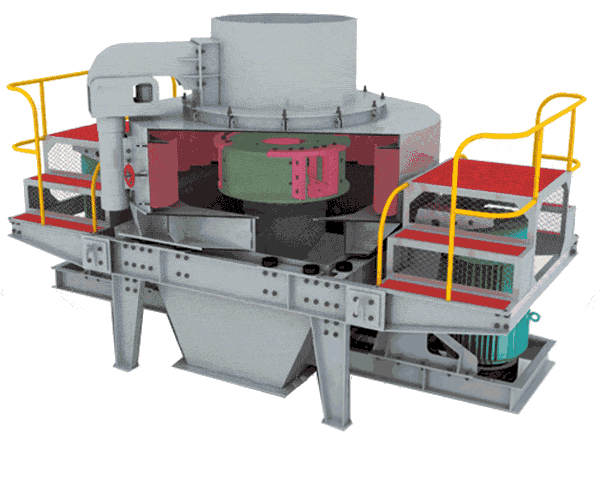

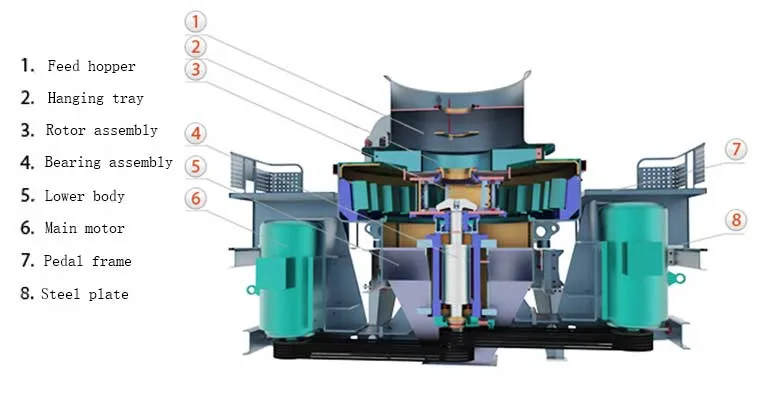

When the VSI crusher is working, driven by the motor, the rotor runs at high speed. The material falls vertically into the high-speed rotating impeller from the feeding port at the upper end of the VSI stone sand making machine. The high-speed rotor throws the material to the impact plate in the crushing chamber. The material not only collides violently with the impact plate, but also collides and breaks with the material. Then the material bounces from the counter liner back to the blow hammer and breaks again. This process is repeated until the stone meets the standard size and falls out of the discharge opening.

VSI vertical sand making machine comprises the casing, rotor, main shaft device, cooling device, motor, transmission pulley, and electric control cabinet.

优势Advantages

1. High output and high efficiency: The optimized design of the deep cavity rotor increases the material throughput by about 30%.

2. Long service life: The service life is increased by more than 40%, reducing daily fault repairs, saving costs, and improving efficiency;

3. Excellent sand particle type: The processed river pebble sand particle has a beautiful appearance, reasonable gradation, and adjustable fineness modulus.

4. Environmental protection is in place: The deep cavity turbine design, good exhaust system, and efficient dust removal equipment are used to reduce dust pollution; in addition, the equipment operates smoothly, reduces the body’s vibration, and reduces the noise of equipment startup and operation.