- output:55t/h

- Feed size:45mm

- Motor power:90kw

PCL Vertical Shaft Impact Crusher is also called PCL sand making machine.It is widely used for crushing various kinds of ores,cement,fire-proof materials,bauxite,corundum,glass raw material,building sand, stone materials and other metallurgical slags.Also,it is especially efficient to crush materials with strong hardness and good corrosion resistance,such as carborundum,corundum and magnesium sand.

| 规格型号 Model | 最大入料粒度 | 功率 | 叶轮转速 | 处理量 | 外形尺寸 | 重量 |

| Max.feed size(mm) | Power(kw) | Impeller speed(r/min) | Capacity(t/h) | Dimension(mm) | Weight(kg) | |

| PCL-600 | 35 | 22-55 | 2000-2600 | 12-30 | 2500×1600×2260 | 5600 |

| PCL-750 | 45 | 45-90 | 1500-2500 | 25-55 | 2780×1800×2700 | 7300 |

| PCL-900 | 50 | 90-180 | 1200-2000 | 55-100 | 3900×2160×2770 | 12100 |

| PCL-1050 | 60 | 150-264 | 1000-1700 | 100-160 | 4660×2450×3660 | 16900 |

| PCL-1250 | 60 | 264-440 | 850-1200 | 160-300 | 5600×2950×4000 | 22000 |

| PCL-1350 | 60 | 320-440 | 800-1193 | 200-360 | 5340×2940×3650 | 26000 |

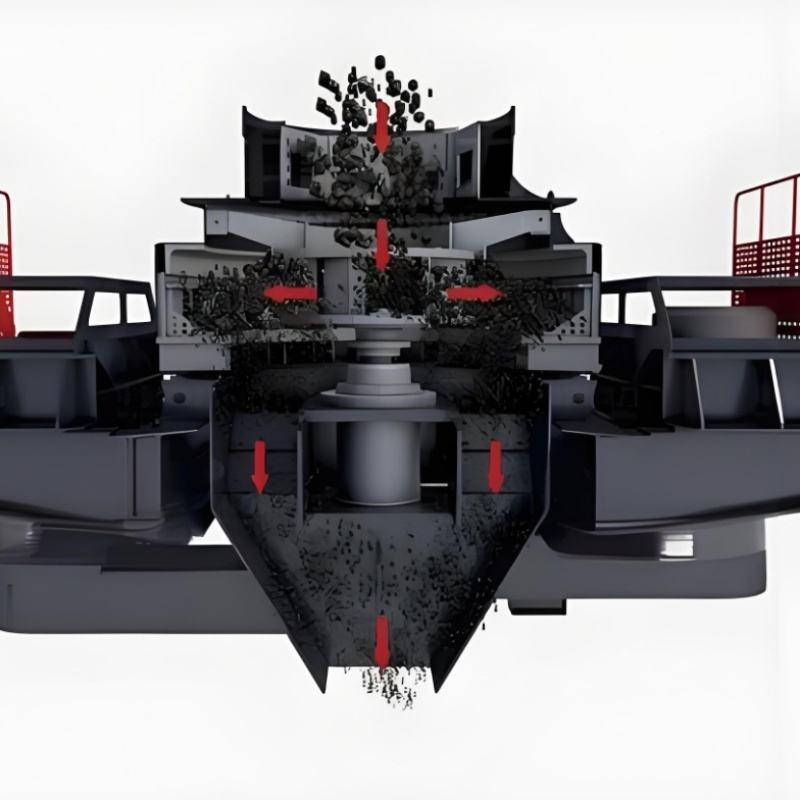

The supplies are falling into the whirling impeller of high speed vertically by the top of the machine, under high-speed centrifugal function, the supplies shunted with another part around the impeller in the form of the umbrella produce at a high speed, striking and crushing. Supplies which not bumping into each other, can form vortex striking with each other between impeller and chassis. The crushed materials will be discharged from the underpart directly, forming a lot of circulation of closed path.

They will be sieved by the equipment and reaches the grain size of finished product required.

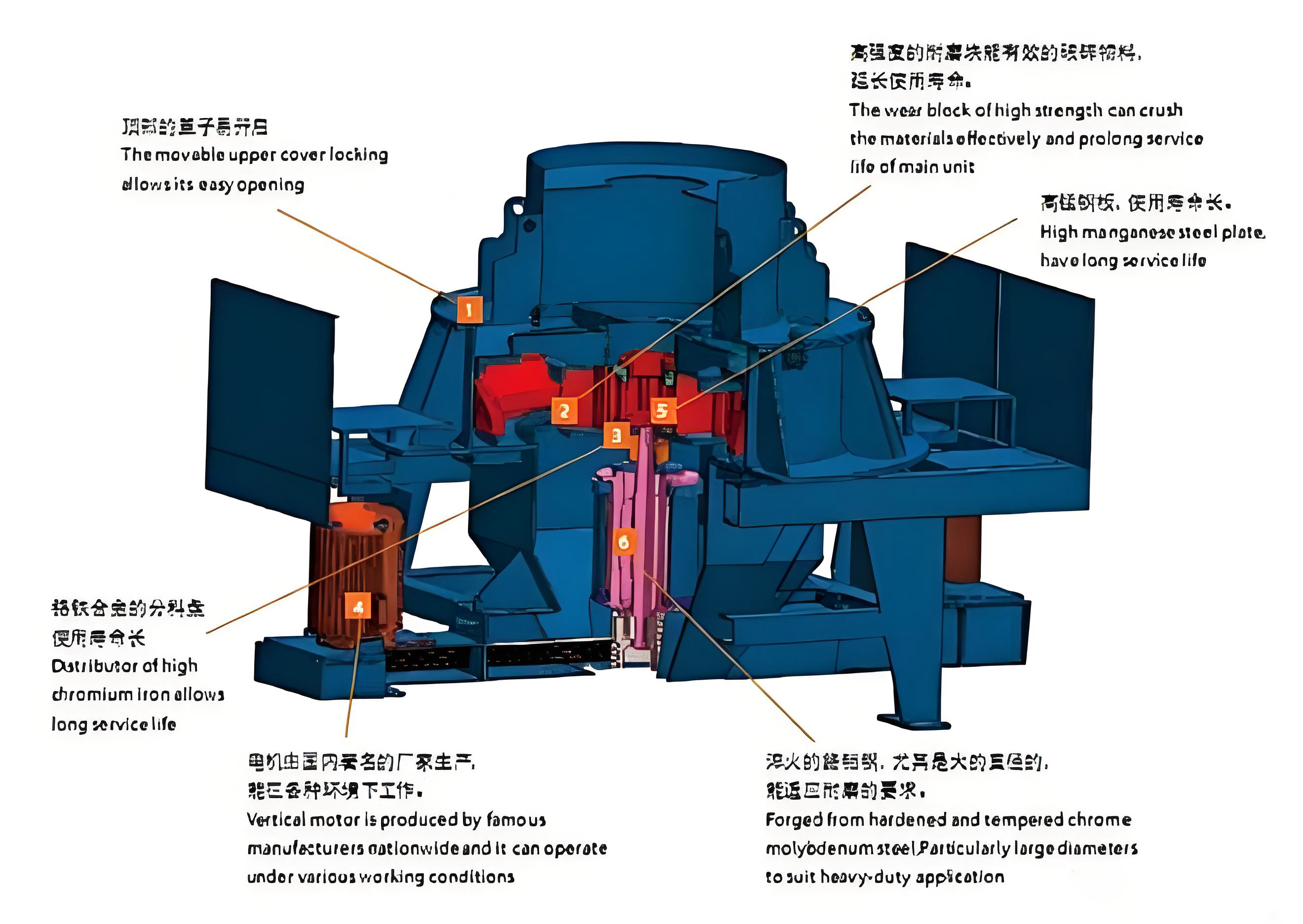

Understanding the main parts of a VSI crusher helps with operation and maintenance.

Hopper: Where the feed material enters the machine.

Distributor Plate: A small but critical plate that evenly distributes feed into the rotor.

Rotor: The heart of the machine. It spins at high speed to accelerate the material.

Crushing Chamber: The main body where the rock-on-rock or rock-on-anvil impact happens.

Wear Parts: Replaceable components inside the machine, such as rotor tips and wear plates, that protect the main structure.

Main Shaft Assembly: The precision-engineered shaft and bearing system that supports and spins the rotor.

Drive System: The motor and belts that power the machine.

优势Advantages

1. The structure is simple and reasonable, and the operating cost is low.

2. High efficiency and energy saving, with two functions of fine crushing and coarse grinding.

3. It is less affected by the moisture content of the material, and the moisture content can reach about 8%.

4. The product is cubic, with high bulk density and low iron pollution.

5. Strong wear resistance and long service life. The impeller self-lining of the sand-making machine is small in wear and easy to maintain.

6. Low noise and low dust pollution, which is good for protecting the environment.