- output:≤40mm

- Feed size:20t/h

- Motor power:45KW

High efficiency fine crusher is the most effective,practical and reliable gravel machine.It is suitable for crushing granite,basalt,limestone,river gravel,cement clinker,quartz,iron ore,bauxite and other minerals.It also applies to artificial sand,highway,railway,water conservancy,airport,construction,cement,refractory, metallurgical and other industries for the production of superior quality stone.

| 规格型号 Model | 主轴转速(rpm) Rotation speed of main shaft | 锤头数量 Quantity of hammers | 转子直径 Diameter of rotor(mm) |

转子长度 Length of rotor(mm) |

入料粒度Input size (mm) | 出料粒度 Output size(mm) |

电机功率 Power(kw) | 处理能力 Capacity(t/h) | 外形尺寸Dimension(m) |

| 800×400 | 860 | 12 | 800 | 400 | ≤40 | 5 | 37-45 | 10-20 | 2.1×1.4×1.7 |

| 800×600 | 860 | 18 | 800 | 600 | ≤50 | 5 | 45-55 | 15-25 | 2.1×1.62×1.7 |

| 800×800 | 860 | 24 | 800 | 800 | ≤60 | 5 | 45-55 | 20-30 | 2.1×1.84×1.96 |

| 1010×1010 | 720 | 30 | 1010 | 1010 | ≤80 | 5 | 55-75 | 40-60 | 2.1×1.84×1.96 |

| 1200×1000 | 590 | 30 | 1200 | 1000 | ≤100 | 5 | 90-110 | 50-70 | 2.45×1.6×1.96 |

| 1200×1200 | 590 | 24 | 1200 | 1200 | ≤100 | 5 | 110-132 | 70-109 | 3.0×2.16×2.5 |

| 1400×1400 | 540 | 24 | 1400 | 1400 | ≤120 | 5 | 132-160 | 120-160 | 3.0×2.36×2.55 |

| 1600×1600 | 460 | 24 | 1600 | 1600 | ≤120 | 5 | 220-250 | 160-200 | 3.0×2.76×2.5 |

| 1800×1800 | 420 | 24 | 1800 | 1800 | ≤150 | 5 | 280-315 | 200-240 | 3.0×3.26×3.15 |

The working principle of the high-efficiency fine crusher mainly relies on the high-speed rotating hammer or blade to hit, cut and crush the material. The material enters the cavity through the feed hopper and is repeatedly hammered and cut by the high-speed rotating hammer or blade, thereby achieving the effect of fine crushing.

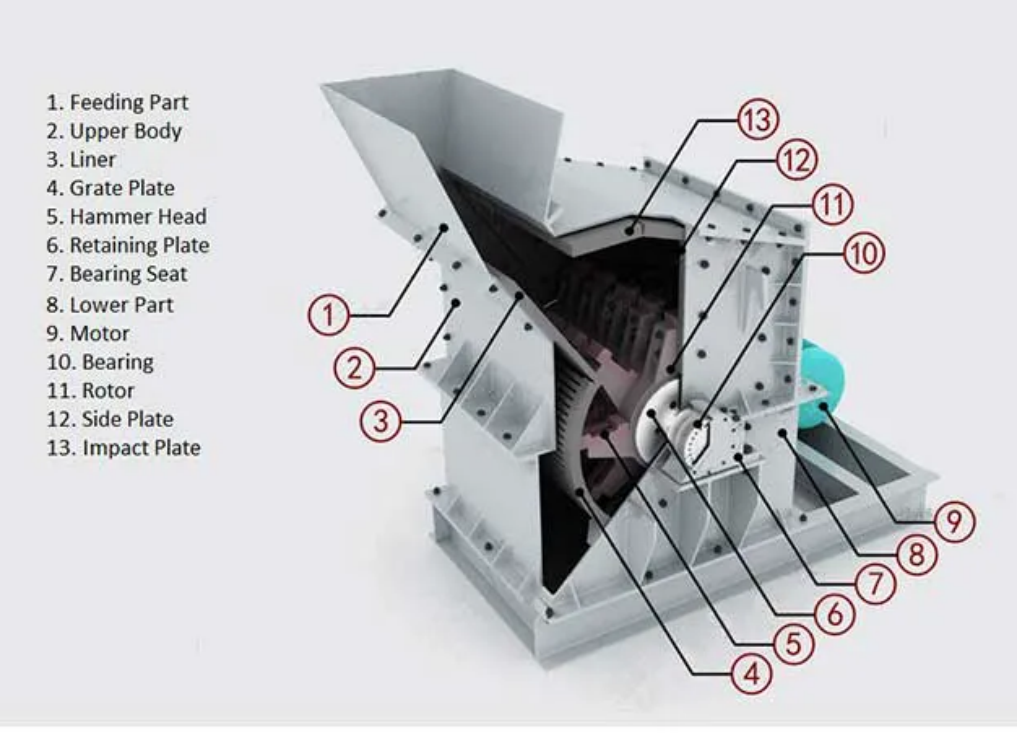

This equipment mainly consists of a rotary section, a guard plate section, and a box section. The wheel core of the rotary section is equipped with multiple non-overlapping hammer frames, and the hammer heads are fixed onto these frames. The width of the hammer heads exceeds that of the hammer frames and the wheel hubs. The wheel core is integrally formed by several wheel hubs and is fixed onto the main shaft. Both ends of the main shaft are supported on the frame by rolling bearing seats. The guard plate assembly is divided into several pieces and fixed onto the box to protect it from wear, while forming various types of impact crushing chambers. The box is divided into upper and lower parts, connected by bolts for easy disassembly, assembly, and maintenance.

优势Advantages

1.Discharging granularity is adjustable.

2.Sieve plate adopts special spring concession structure, simple, convenient, reasonable, safe and stable.

3.Adopt elasticity constant force and make crushing force stable.

4.Adopt high alloy hammer head, it can reduce abrasion, extend lifespan, and has high efficiency.

5.Mixing pad can exchange, also can increase the lifespan. Do not block and it has high safty.

6.Compared with hammer crusher and impact crusher, it can only wear rotor, and can not wear wheel core and hammer carrier.

7.It is easy to maintain, we only need to hoist the upper box, and open the lower box.

8.Adopt multi-layer three channel discharging device, it can discharge the material at time, and improve the capacity.

9.Adopt solid rotor, rotational inertia, and strong hitting power.